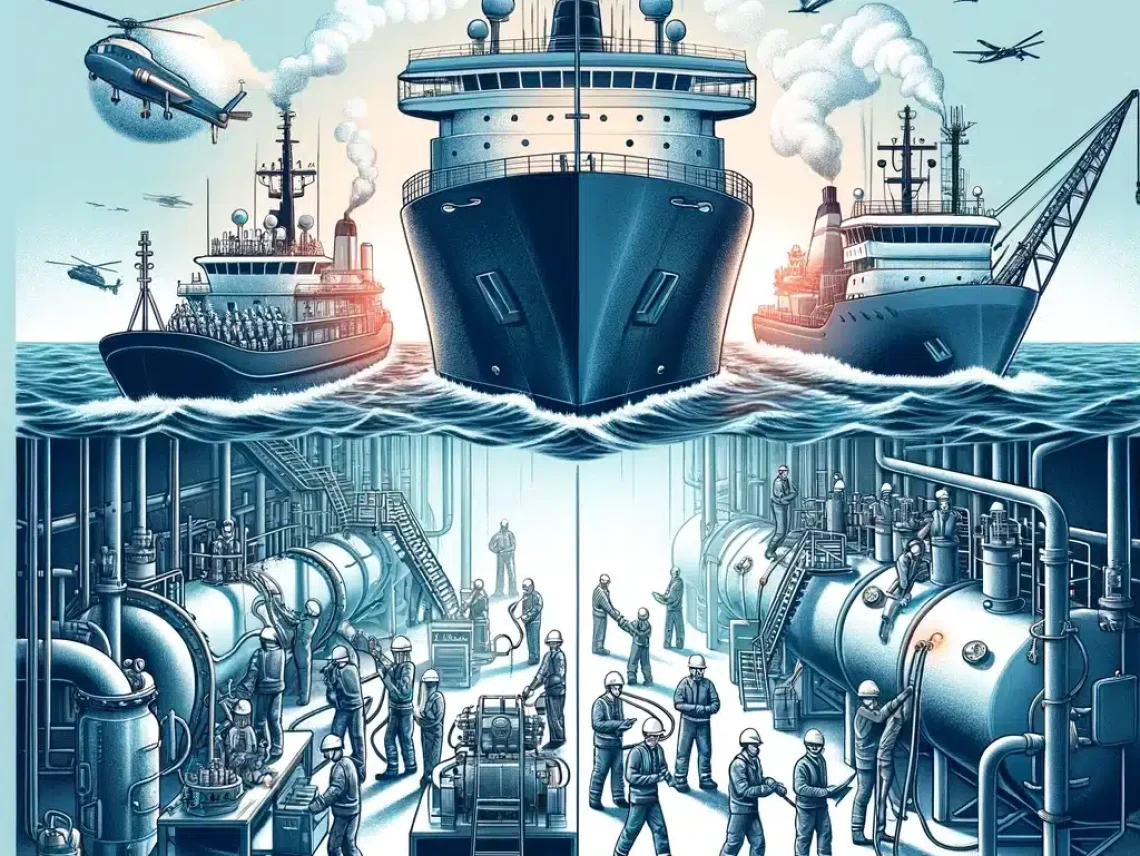

Ship operations encompass a wide spectrum of essential activities, from navigation and maritime management to complex cargo handling and onboard systems maintenance. At Red River, we recognize that these functions are at the heart of modern ship operations. Our pressure vessels are built to support this critical work integrating seamlessly into a dynamic marine environment where safety, efficiency, and regulatory compliance are paramount.

The maritime enterprise has evolved dramatically through the years, and so have vessel operations. This evolution resonates with our adventure at Red River. Just as ship operations have evolved with advanced technologies and safety protocols, Red River has modernized its manufacturing practices to meet these changing standards. Our modern-day technology and adherence to stringent protection standards mirror this evolution, ensuring that our pressure vessels meet the ever-changing demands of the maritime industry.

Vessel operations are the backbone of global trade. They facilitate the movement of goods throughout oceans, connecting markets and fueling economies. At Red River, we recognize the importance of this function. Our pressure vessels are not just products; they are vital components that support the efficiency and protection of maritime operations. We take pleasure in understanding that our vessels play a component in this critical global network.

The scope of ship operations includes several mission-critical roles performed by crew and operators across all maritime vessels. Navigational management and protection are paramount, concerning unique path planning and adherence to protection protocols to defend the vessel and crew.

Efficient cargo management and stowage are critical elements of successful ship operations. Properly loaded cargo maintains vessel balance, ensures safe navigation, and prevents damage during transit. In international trade, optimizing stowage plans directly impacts delivery timelines and port efficiency. Modern ship operations rely on digital cargo planning systems to improve space utilization and comply with international load line regulations.

To see how our engineered pressure vessels support secure and balanced cargo transport, visit our Pressure Vessels page.

Routine vessel maintenance is the backbone of reliable ship operations. Scheduled inspections, system diagnostics, and timely repairs ensure the vessel remains seaworthy and compliant with safety standards. Preventive upkeep minimizes breakdowns and helps ship operators avoid costly delays or detentions at ports. In today’s high-demand logistics world, the quality of maintenance defines the resilience of ship operations.

Automation has transformed ship operations by streamlining repetitive tasks, reducing crew workload, and minimizing human error. From automated ballast systems to AI-driven route planners, automation enhances decision-making speed and safety across all shipboard systems. Ships with advanced automation can run more efficiently and meet stricter emissions and safety standards.

State-of-the-art navigational systems are at the heart of safe and efficient ship operations. Tools such as ECDIS (Electronic Chart Display and Information Systems), GPS integration, and real-time AIS tracking provide unparalleled situational awareness. These advancements support route optimization, minimize collision risk, and reduce fuel costs, making navigation smarter and more compliant.

AI-driven insights are revolutionizing ship operations by enabling predictive maintenance, autonomous route selection, and operational risk alerts. By analyzing sensor data across propulsion, fuel, and weather systems, AI ensures more reliable voyages. Shipowners embracing AI in ship operations gain a competitive edge through improved safety and fuel efficiency.

Navigational management and protection are paramount, concerning unique path planning and adherence to protection protocols such as those defined in the SOLAS NVIC guidance to defend the vessel and crew.

Ongoing training programs for maritime crews are essential for compliant and effective ship operations. These programs cover new technologies, environmental regulations, and updated safety standards. Operators who invest in crew development ensure smoother day-to-day shipboard performance and regulatory compliance.

The well-being of crew members directly affects performance in ship operations. Modern practices focus on reducing fatigue, improving living conditions, and ensuring mental health support. Prioritizing safety and welfare builds trust and increases retention in a competitive labor market.

Operators must comply with international regulations such as SOLAS (International Convention for the Safety of Life at Sea, 1974) and MARPOL – the Convention for the Prevention of Pollution from Ships core pillars of safe and environmentally compliant ship operations.

Sustainability is central to future-proof ship operations. Stricter emission standards, ballast water management rules, and fuel sulfur limits require ships to adopt cleaner technologies and optimized voyage planning. Failing to comply can result in heavy fines or denied port entry.

Operating in international waters demands rigorous documentation and continuous regulatory updates. Successful ship operations require up-to-date knowledge of port state control requirements, flag state responsibilities, and region-specific laws. Proactive compliance planning is now a competitive advantage.

Tight financial controls are essential in ship operations to maintain profitability amid rising fuel and regulatory costs. Budgeting for maintenance, training, and compliance helps prevent costly surprises. Smart operators track operational KPIs to optimize resource allocation across their fleets.

The efficiency of ship operations directly impacts freight rates. Delays, safety issues, or maintenance failures raise costs that are eventually passed on to clients. Conversely, streamlined ship operations reduce turnaround times and boost a vessel’s marketability.

Balancing high performance with cost-efficiency is the core challenge in ship operations. Technologies like voyage optimization software and hybrid propulsion systems help ships run leaner while meeting performance benchmarks. Success lies in minimizing waste without compromising safety.

From weather volatility to piracy, ship operations face numerous risks. A robust risk management system includes real-time threat monitoring, incident simulation drills, and insurance alignment. Proper planning ensures business continuity even under adverse conditions.

Effective crisis management is a defining trait of professional ship operations. This includes fire response, man-overboard procedures, and communication protocols during equipment failure. Trained crews and clear SOPs turn potential disasters into manageable situations.

Marine insurance plays a vital role in risk mitigation for ship operations. Policies must reflect the ship’s routes, cargo types, and flag state laws. Liability awareness among operators prevents costly litigation and ensures financial protection.

Stricter emission standards, ballast water management rules, and fuel sulfur limits such as those outlined under MARPOL Annex VI & APPS require ships to adopt cleaner technologies and optimized voyage planning.

Advanced propulsion technologies, cleaner fuels, and optimized routes help reduce the carbon intensity of ship operations. Operators that embrace ESG (Environmental, Social, Governance) practices gain reputational and regulatory advantages.

Technologies like scrubbers, shore power, and solar-assist systems enable more sustainable ship operations. Investment in R&D and fleet retrofitting is key to meeting 2030 and 2050 climate targets set by global authorities.

Autonomous navigation, blockchain in cargo tracking, and real-time emissions reporting are reshaping ship operations. As the maritime industry digitizes, early adopters stand to gain the most in efficiency and regulatory alignment.

Digital twin technology, remote diagnostics, and AI-powered maintenance forecasting are revolutionizing how ship operations are managed. Future ships will rely more on data centers and analytics than traditional engineering alone.

By 2035, most ship operations will be semi-autonomous, with digital crew interfaces and continuous emissions optimization. Safety, sustainability, and speed will converge as core performance metrics.

As the maritime industry evolves, ship operations remain the critical link between vessel performance, regulatory compliance, crew welfare, and environmental responsibility. At Red River, we understand that reliable, efficient operations at sea begin with the right equipment, training, and vision. From automation to sustainability, the future of ship operations lies in intelligent integration where technology, safety, and strategic foresight work together.

Whether you’re managing a single vessel or an entire fleet, optimizing ship operations is no longer optional it’s essential for resilience, profitability, and regulatory alignment in a global economy.

When designing a pressure vessel, the most critical factors include material selection, which must withstand the internal pressures and chemical properties of the stored substances; design pressure and temperature, ensuring the vessel can operate safely under maximum expected conditions; and compliance with industry standards like ASME, ensuring structural integrity and safety. Additionally, the vessel’s intended use, such as storage or reaction, significantly influences its design.

Environmental factors play a crucial role in pressure vessel design and material selection. Corrosive environments require corrosion-resistant materials like stainless steel or special coatings. Extreme temperatures necessitate materials with high thermal stability. Additionally, external factors like seismic activity or exposure to harsh weather conditions must be considered to ensure the vessel’s durability and safety.

Current advancements in pressure vessel manufacturing include automation in welding and fabrication processes, enhancing precision and efficiency. The use of advanced materials like composites for lighter, stronger vessels is gaining traction. Additionally, digital technologies like 3D modeling and simulation software are revolutionizing design processes, allowing for more accurate stress analysis and optimization of vessel geometry.

Yes, pressure vessels can be extensively customized to meet specific industry needs, including size, shape, material, and internal configurations. However, customization is limited by factors like material properties, safety standards, and manufacturing capabilities. For instance, while larger vessels offer more capacity, they require thicker walls and more robust support structures, which can impact cost and feasibility.

Modern pressure vessels incorporate several key safety features, such as pressure relief valves to prevent over-pressurization, corrosion-resistant materials and coatings to prevent leaks, and non-destructive testing methods for regular safety inspections. Additionally, advanced monitoring systems can provide real-time data on vessel conditions, enabling proactive maintenance and safety management.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.