Vessels for fuel cell systems are essential for safely storing, regulating, and delivering hydrogen under high pressure, enabling reliable operation across transportation, industrial, and power generation applications. Advanced materials, strict ASME/ISO standards, and ongoing design innovations make these vessels the structural backbone of scalable, clean hydrogen energy infrastructure.

How Vessels for Fuel Cells Power Clean Energy Systems

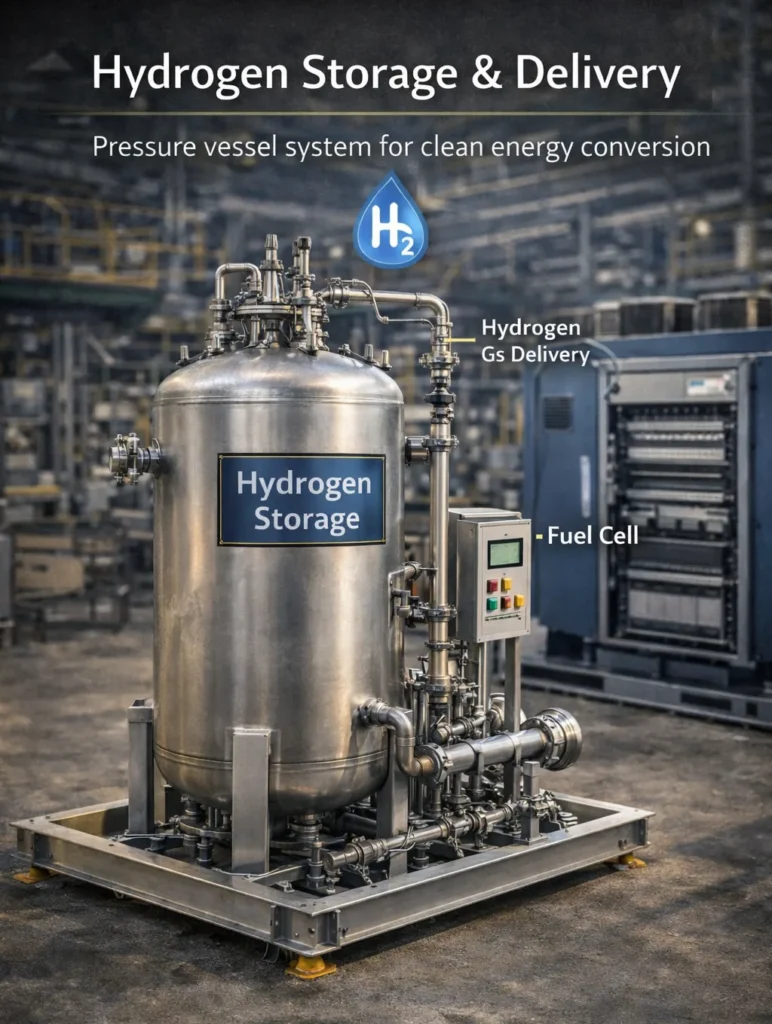

Vessels for fuel cells are critical components in modern clean energy infrastructure, particularly within fuel cell energy systems. These vessels are specifically engineered to support safe hydrogen storage, precise pressure regulation, and consistent fuel delivery across next-generation power applications. As hydrogen adoption expands into transportation, grid-scale power generation, and off-grid solutions, pressure vessels provide the structural backbone required to store and manage compressed gases under extreme conditions.

Companies specializing in engineered containment systems, such as those producing custom pressure vessels and modular energy equipment, play a key role in enabling scalable hydrogen infrastructure. Without advanced vessel design and fabrication expertise, maintaining safety and performance benchmarks would be impractical.

Function of Vessels for Fuel Cells Energy Systems Explained

Vessels used in hydrogen and fuel cell systems support multiple operational requirements across the hydrogen value chain:

- Hydrogen Storage: High-pressure containment (350–700 bar) enables on-demand energy availability, similar to applications discussed in why you would need a pressure tank.

- Pressure Regulation: Integrated systems reduce storage pressure to fuel-cell-ready levels.

- Thermal Management: Vessel design mitigates temperature swings caused by compression and expansion.

- Safety Containment: Built to exceed failure thresholds outlined in pressure vessel safety and compliance standards.

- Fuel Distribution: Used in skid-mounted and mobile systems, often integrated into modular skids for faster deployment.

These functions ensure fuel cell systems operate reliably in real-world environments.

Common Vessel Types Used in Fuel Cell Infrastructure

The vessel configuration depends on system mobility, pressure demands, and lifecycle goals:

- Type I Steel Cylinders: Common in stationary installations and industrial energy systems.

- Type II Hybrid Vessels: Steel liners with composite reinforcement to reduce mass.

- Type III Composite Vessels: Aluminum liners with carbon fiber wrap, frequently used in transportation.

- Type IV All-Composite Vessels: Polymer liners with full composite structures, similar to designs explored in Type 4 pressure vessel technology.

- Buffer Tanks: Stabilize pressure fluctuations, aligning with concepts explained in pressure tanks vs pressure vessels.

Each vessel type balances safety, cost, and performance requirements.

Material and Design Standards

Vessels in fuel cell energy systems must comply with rigorous engineering standards:

- High Burst Pressure Ratings: Designed beyond operational limits as outlined in failure criteria for pressure vessels.

- Hydrogen Compatibility: Materials selected using best practices from choosing the right material for pressure vessel fabrication.

- Leak-Proof Construction: Advanced welding and inspection methods supported by ASME-certified pressure vessel standards.

- Thermal Resistance: Performance across wide temperature ranges.

- Weight Optimization: Critical for automotive and mobile energy systems.

Compliance with ASME Section VIII and ISO standards ensures global deployability, as discussed in demystifying ASME pressure vessel certification.

Applications Across Fuel Cell Sectors

Vessels in fuel cell energy systems serve a wide range of industries and uses:

- Automotive: Hydrogen storage tanks for cars, buses, and trucks.

- Backup Power: Telecom and data center systems similar to those described in pressure vessels in power generation.

- Maritime & Aviation: Emerging zero-emission vessel and aircraft platforms.

- Power-to-Gas Systems: Renewable hydrogen storage for grid balancing.

- Industrial Energy: On-site generation for campuses and factories, often paired with prefabrication solutions.

These applications highlight the growing reliance on pressure vessel technology in the hydrogen economy.

Manufacturing Challenges and Opportunities

Developing vessels in fuel cell energy systems presents unique manufacturing considerations:

- Composite Fabrication Expertise: Required for Type III and Type IV lightweight vessels.

- Leak Testing and Validation: Techniques aligned with pressure vessel inspection best practices.

- Mass Production Scalability: OEMs must produce vessels with speed, consistency, and compliance.

- Integration with Skid Packages: Modular designs simplify transport and installation for industrial clients.

- Recyclability and Lifecycle Management: Especially critical for EV and consumer-facing fuel cell applications.

These challenges drive innovation in pressure vessel manufacturing processes and quality assurance.

Innovations in Fuel Cell Vessel Design

Recent developments in vessels in fuel cell energy systems include:

- Smart Vessels: Sensors embedded into the vessel walls for real-time pressure, temperature, and leak monitoring.

- 3D-Printed Components: Additive manufacturing allows for internal baffle customization.

- Hydride-Based Storage Vessels: For low-pressure solid-state hydrogen absorption and release.

- Lightweight High-Capacity Tanks: Using graphene-reinforced composites for reduced mass and higher burst resistance.

- Thermally Adaptive Liners: Materials that adjust insulation properties based on ambient conditions.

Many of these innovations build upon foundational principles outlined in understanding the purpose of a pressure vessel.

The Backbone of Fuel Cell Infrastructure

Vessels for fuel cells energy system are more than just containers—they are precision-engineered assets designed to meet the unique demands of hydrogen storage and delivery. These vessels for fuel cells play a vital role in safeguarding the fuel supply, regulating energy output, and maintaining consistent operational safety across diverse applications. As global energy systems shift toward cleaner, hydrogen-based solutions, the need for advanced vessels for fuel cells has grown significantly. High-performance, regulation-compliant vessels for fuel cells are now indispensable in automotive fuel cell technology, industrial hydrogen systems, and stationary power generation. Whether used in vehicles, commercial operations, or decentralized power systems, vessels for fuel cells provide the backbone for reliable, safe, and scalable hydrogen energy infrastructure. Their ability to maintain integrity under pressure, prevent leakage, and optimize fuel flow ensures that fuel cell systems operate efficiently and sustainably in a range of demanding environments.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. Why are vessels important in fuel cell energy systems?

They store and regulate hydrogen or other fuels under pressure, ensuring safe and efficient delivery to the fuel cell.

2. What types of vessels are used in hydrogen fuel cells?

Common types include composite-wrapped cylinders (Types III and IV), buffer tanks, and hybrid steel-composite vessels.

3. What standards apply to these pressure vessels?

ASME Section VIII, ISO 11119, and DOT regulations define material, pressure, and safety standards for these vessels.

4. Are there specific materials best suited for hydrogen?

Yes. Stainless steel, aluminum alloys, and composites are often used due to their resistance to hydrogen embrittlement and lightweight properties.

5. Can fuel cell vessels be used in mobile and stationary systems?

Absolutely. They are designed for both applications, with different designs optimized for automotive, grid, or industrial use.

Key Takeaways

- Vessels in fuel cell energy systems support clean energy by safely storing and delivering pressurized hydrogen.

- Applications span from vehicles and power grids to marine and aerospace systems.

- Vessel types include steel, hybrid, and composite options tailored for specific demands.

- Standards like ASME and ISO ensure vessel integrity, safety, and performance.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author