ASME pressure vessel welding requires certified welders, approved materials, strict adherence to Section IX codes, thorough inspections, and complete documentation to ensure safety, reliability, and code compliance. Prefabrication in controlled environments further improves quality, reduces costs, and minimizes on-site risks while maintaining consistent, defect-free welds.

Understanding What Are the Requirements for ASME Pressure Vessel Welding

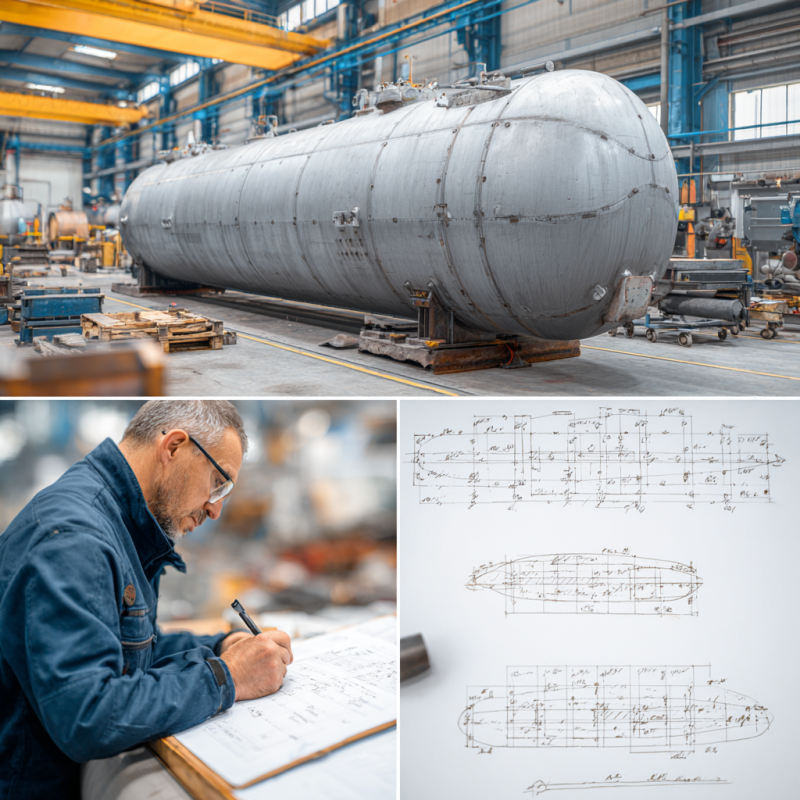

If you’re asking “what are the requirements for ASME pressure vessel welding,” you’re likely aiming to build or maintain a system that can handle high pressures safely. Meeting the American Society of Mechanical Engineers (ASME) standards is crucial for many industries, ranging from petrochemicals to pharmaceuticals. In this guide, we’ll explore the key factors behind ASME-compliant pressure vessel welding. You’ll discover why proper code adherence, certified welders, and robust quality checks matter. And the good news, as confirmed by experts such as Red River, is that this process can be more straightforward when you know the fundamentals.

What are the ASME pressure vessel welding requirements

At the core of pressure vessel production, ASME regulations define how you must handle design, materials, welding procedures, and final testing. These requirements come from the ASME Boiler and Pressure Vessel Code (BPVC), which provides guidelines for safe construction and inspection. You need to ensure that your procedures and personnel all align with this code. Below are the most critical aspects:

- Compliance with ASME BPVC Section IX on welding and brazing qualifications

- Use of code-approved materials and procedures

- Employment of qualified, certified welders

- Adherence to rigorous inspection and testing processes

- Detailed documentation, including material traceability and welder logs

If you’re new to the topic, you might want to check the basics of pressure vessel welding to see why these requirements matter so much. For an overview, see what pressure vessel welding.

By following ASME protocols, you reduce risks such as vessel rupture or hazardous leaks. Each requirement works together to ensure safety, reliability, and longevity for your pressure vessels. Let’s examine each part more closely.

Follow ASME code guidelines

ASME’s guidelines set the baseline for vessel design, welding, and quality control. They specify welding procedure qualifications, acceptable filler metals, preheat temperatures for various materials, and inspection measures. According to Red River, an ASME-certified manufacturer with U4 & R stamps, this certification ensures that any vessel meets strict dimensional and structural guidelines.

Why the code matters

- Safety first: When a pressure system fails, the results can be catastrophic. ASME standards are there to prevent such incidents, requiring robust designs and steady welding practices.

- Legal compliance: In many regions, local regulations insist on ASME certification, particularly for large-scale operations that handle high pressures.

- Repeatability: The code ensures consistent, repeatable outcomes. If you follow standardized guidelines, your vessel’s reliability is not left to chance.

When preparing to tackle ASME welding tasks, you’ll often start by qualifying your Welding Procedure Specification (WPS). A WPS outlines the materials, positions, filler metals, and joint details. You also need a Procedure Qualification Record (PQR) to document testing results for that procedure. Section IX mandates these elements to confirm that the welding technique can produce sound joints.

For more insights into which welding processes work best, try reading what welding process is used for pressure vessels. It sheds light on different methods and how they align with ASME rules.

Use certified welders

Even with a perfect welding procedure, you still need skilled hands. Under ASME requirements, welders must pass a performance qualification that demonstrates their ability to create defect-free welds. This involves hands-on tests with destructive or non-destructive evaluations.

How welders become certified

- Training: Many companies, such as Red River, offer in-house or external training to prepare employees for welding tests.

- Testing: Individuals take a welder performance qualification test under Section IX protocols. They weld a coupon that then undergoes X-rays or other inspections.

- Documentation: Once proven effective, the welder’s performance record is documented. This record must match the WPS/PQR being used on the job.

A recurring question is how long these certifications last. Often, they remain valid as long as the welder continues to use the qualified process within a specific time period. If you’d like more details, you can look at how long pressure vessel welding certification last.

Why certified welders matter

- Reduced error: Certified welders have the know-how to minimize porosity, cracks, or other weld flaws.

- Code compliance: Each welder’s documentation ties back to a recognized standard, ensuring your project meets ASME demands.

- Peace of mind: You know your operations won’t stall due to welding rework or safety breaches.

Apply prefabrication benefits

Prefabrication is a growing approach in the pressure vessel world. Instead of performing all the welding on-site, you can do much of the work in a controlled manufacturing environment. Red River, for instance, highlights cost savings and better quality in prefabricated skids and modules. Prefabrication helps you:

- Control environment: Inside a workshop, you can keep humidity, temperature, and contamination in check, which improves weld consistency.

- Reduce on-site exposure: By completing assemblies beforehand, fewer people face on-site hazards. This can lead to improved incident rates.

- Cut costs: Fewer mistakes and faster construction mean cost savings. Shipment and inspection also become easier, as everything is already assembled or partially complete.

With this method, conflict resolution also tends to be quicker, since you can identify design overlaps or geometry issues before they reach the field. For a deeper look at on-site best practices, see how to weld pressure vessels.

Key prefabrication advantages

| Aspect | Benefit |

| Quality | Controlled settings reduce weld defects. |

| Schedule | Less weather or shipping delays. |

| Safety | Fewer on-site hours mean lower risks. |

| Cost | Fewer errors, faster builds, less waste. |

Prefabrication doesn’t just help you speed up production, it also ensures a tighter grip on quality, which aligns perfectly with ASME standards.

Ensure rigorous quality control

Quality control (QC) is a major part of any pressure vessel project. If you look at successful manufacturers like Red River, they emphasize continuous improvement and Lean Six Sigma training, ensuring each stage is meticulously checked. QC typically covers:

- Material traceability: You must confirm that every plate, pipe, or fitting comes from an approved source and meets ASME criteria.

- Welding inspections: Non-destructive testing (NDT) methods, such as radiography or ultrasonic testing, pinpoint internal flaws invisible to the naked eye.

- Documentation: Keeping thorough records proves that each weld meets code. This includes weld logs, welder qualifications, and test results.

Common NDT methods

- Radiographic testing: Uses X-ray beams to detect internal cracks.

- Ultrasonic testing: Employs high-frequency sound waves to find flaws beneath the surface.

- Magnetic particle inspection: Helps reveal surface-breaking defects in ferromagnetic metals.

- Dye penetrant inspection: Uses a fluorescent dye to spot small surface cracks.

If defects are found, welders either repair or replace the section, then retest it. This loop of inspection and correction is fundamental to meeting what the ASME code demands.

Role of documentation

Accurate records provided to an Authorized Inspector are crucial. If your vessel ever experiences an issue, having complete documentation proves you followed the standards. It also makes it easier to perform repairs or alterations later, since you’ll know the component history. For more on best practices, see welding procedure for pressure vessel.

What are the requirements for ASME pressure vessel welding

When you sum it all up, ASME pressure vessel welding pivots on a few major pillars. You need standardized guidelines from Section IX, trained and tested welders, materials that meet code, careful prefabrication to boost efficiency, and intense quality checks through every stage. That might sound like a challenge initially, but once you have the right procedures in place, you’ll see smoother operations, higher safety scores, and confidence in your finished vessel’s integrity.

From choosing the correct filler metal to ensuring each welder’s certification is up to date, each step is essential to keep your project on track. Having an ASME-certified partner, such as vessel welding specialists, can simplify these tasks. They help you handle the codes and documentation without losing time or sacrificing quality. Embracing best practices, such as workshop prefabrication and thorough testing, further ensures that you’re not left with last-minute surprises. By following these essential requirements, you’ll set the foundation for a durable, high-performing pressure vessel.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and modular skids.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently asked questions

1. What is the ASME pressure vessel welding code?

The ASME pressure vessel welding code is a set of standards established by the American Society of Mechanical Engineers that governs the design, fabrication, inspection, and welding of pressure vessels to ensure safety and reliability.

2. How to comply with ASME pressure vessel welding code?

To comply with the ASME pressure vessel welding code, manufacturers and welders must follow approved welding procedures, use qualified personnel, conduct proper testing, and maintain documentation that demonstrates adherence to the code.

3. Can I do all pressure vessel welding on-site?

You can, but prefabrication in a controlled environment often yields better results. It improves weld quality, cuts costs, and reduces on-site hazards.

4. What types of NDT are typically used for ASME vessels?

Radiography and ultrasonic testing are common. Others include dye penetrant and magnetic particle inspection. Each spots different kinds of flaws.

5. Are ASME pressure vessel requirements the same worldwide?

While ASME guidelines are recognized globally, local laws may add extra steps or approvals. Always confirm local regulations before you start.

Key takeaways

- ASME codes protect your team and your investment, setting the bar for safe, reliable pressure vessels.

- Certified welders ensure compliance, reduce defect rates, and help pass inspections.

- Prefabrication in a controlled shop environment saves time, trims costs, and lowers exposure risks.

- Accurate documentation and material traceability create transparency and speed up any needed repairs.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author