A gas turbine fuel water separator vessel is a specialized pressure vessel that removes water from turbine fuel, preventing corrosion, inefficiency, and costly downtime. It ensures clean fuel delivery, longer equipment life, and safe turbine operations.

Understanding What is a Gas Turbine Fuel Water Separator Vessel

If you operate gas turbines for power or industry, keeping fuel clean is crucial. A gas turbine fuel water separator vessel removes water from the fuel stream, helping prevent corrosion and improving combustion efficiency. According to a 2024 industry survey, operators with quality separators saw maintenance costs drop by up to 10% in six months. This article explains how these vessels work, what sets them apart, and why regular maintenance is key. No engineering background needed, just clear info to help you choose or upgrade your fuel water separator for reliable turbine performance.

What Is a Gas Turbine Fuel Water Separator Vessel

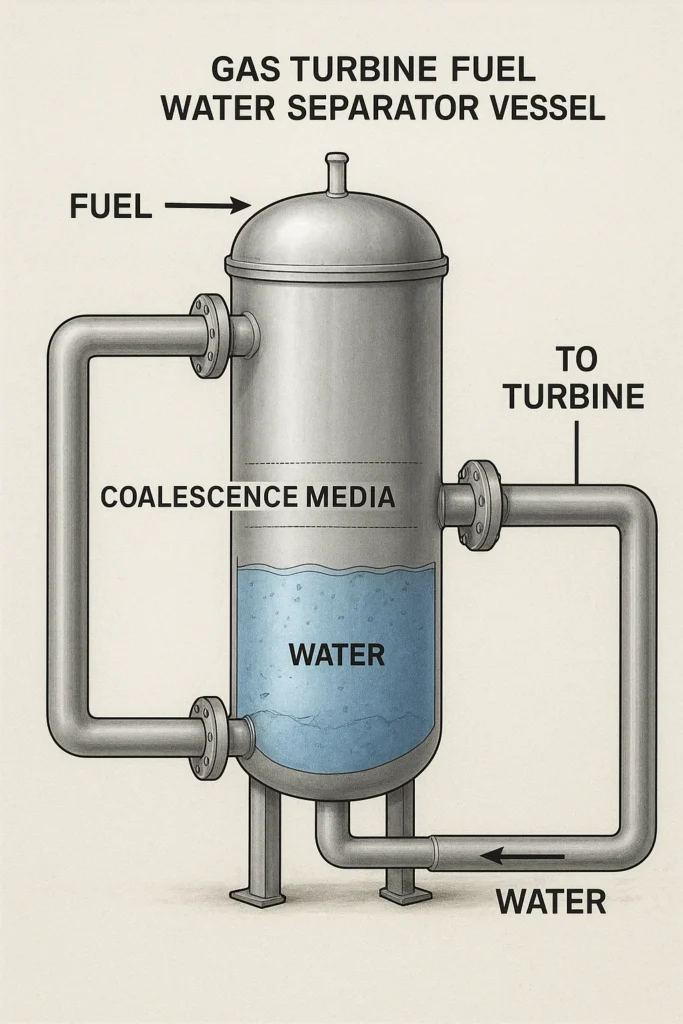

A gas turbine fuel water separator vessel is a specialized pressure vessel designed to remove water contaminants from the fuel you feed into your turbine. Water can be sneaky. It often arrives in your fuel supply through condensation, inconsistent storage conditions, or even transport issues. The job of this separator is to ensure that only dry, clean fuel reaches the turbine’s combustion chamber.

Identifying Water in Your Fuel

- Condensation in storage tanks

- Humid climates causing moisture infiltration

- Improper or leaky fuel handling systems

If left unresolved, water in your fuel can lead to rust, microbial growth, or even ice formation at lower temperatures. Any of these problems can hamper your turbine’s efficiency or, in a worst-case scenario, force a shutdown.

Where the Vessel Fits

The separator is placed upstream of your gas turbine’s fuel system, filtering out water and particles before they reach sensitive parts. Made from thick steel and often built to ASME standards, it ensures safety and durability. Effective separation reduces corrosion, leading to smoother startups, fewer outages, and stable power output. For a similar example in diesel engines, see how a diesel pressure vessel filter separator works. The core goal which is removing water is the same despite different fuels.

Why Separation Matters for Gas Turbines

Gas turbines operate under extremely high temperatures and pressures. These conditions demand a stable, uncontaminated fuel source. Even small amounts of water can lead to:

- Uneven combustion performance

- Extra wear on turbine blades

- Clumping or corrosion in fuel delivery lines

A 2023 reliability test on industrial gas turbines found that turbines using effective fuel water separators had a 15% lower failure rate than those without (Power Engineering Review, 2023). This statistic alone highlights how crucial it is to keep your fuel as clean as possible.

Efficiency and Performance

Removing water improves combustion for better thermal efficiency, steady power, and lower emissions. Over time, this can reduce fuel consumption as the turbine runs more smoothly.

Reduced Maintenance Overhead

Water causes corrosion and sludge buildup, leading to frequent repairs and downtime. Using a fuel water separator lowers these costly maintenance issues.

Safety Considerations

Moisture in fuel can cause surges or misfires, creating unsafe conditions. A well-maintained separator helps prevent these risks.

Key Components and Design

Most gas turbine fuel water separators share key parts that work together to protect your turbine.

Vessel Shell

This pressure-rated steel housing holds the fuel during separation and is often coated to resist corrosion.

Inlet and Outlet Devices

Fuel enters through an inlet with baffles to evenly distribute flow. Clean, water-free fuel exits through the outlet.

Separation Internals

Coalescing filters, mesh pads, or vane packs help water droplets combine and settle at the bottom. Separation uses gravity or centrifugal force.

Example Internal Elements:

- Coalescing filters: encourage small droplets to merge

- Baffles: control fluid movement for steady separation

- Drain or sump: collects and removes water

Automatic Drainage System

Once water gathers at the bottom, it must be evacuated. High-quality separator vessels often include an automatic drain system that detects water levels and opens a valve to remove it. This design minimizes manual intervention and helps keep the system running continuously.

Maintenance Best Practices

Whether you have a large-scale industrial plant or a smaller on-site turbine, consistent maintenance keeps your separator vessel performing well. You are essentially extending the service life of both the separator and the turbine itself.

Routine Inspections

Plan to inspect your separator regularly. Look for:

- Rust or pitting on internal surfaces

- Condition of coalescing or filter elements

- Proper valve operations, particularly drainage valves

Spotting early signs of wear or clogging can save you from bigger problems down the road. For instance, a worn-out coalescing filter can allow water to slip through and damage your turbine.

Timely Filter Replacements

Filters have a finite service life. If you go too long without changing them, you risk allowing more water to remain in the fuel. Consult your manufacturer’s guidelines for recommended intervals. In high-demand environments with continuous operations, these intervals may be shorter than in slower-paced settings.

Calibration Checks

Some separators rely on instrumentation or sensors to monitor water levels. Schedule regular sensor calibrations to ensure they accurately detect changes and stop water from accumulating beyond safe limits.

Professional Servicing

If you encounter leaks, unusual vibrations, or frequent draining, it might be time to call in the experts. A thorough tune-up by a professional service team can correct alignment issues, replace worn parts, and return your vessel to peak efficiency. Red River, for example, specializes in pressure vessel manufacturing and prefabricated solutions and can often tailor a vessel to your unique operating requirements.

What Is a Gas Turbine Fuel Water Separator Vessel

It is your first defense against water contamination, protecting your turbine’s performance and investment. By removing water before combustion, it reduces wear, balances combustion, and lowers operating costs. A well-maintained separator helps prevent outages and extends equipment life.

To learn more, explore a gas turbine fuel water separator vessel solution that fits your setup. Though one part of a larger system, it greatly impacts uptime and costs. Even small water leaks can cause major problems, so quality-built separators are essential.

Keep Your Gas Turbine Running Smoothly and Choose Quality Fuel Water Separators Today!

Don’t let water contamination slow you down. Upgrade to a high-quality gas turbine fuel water separator vessel and experience smoother startups, lower maintenance costs, and longer equipment life. Contact Red River now to find the perfect solution tailored to your needs and ensure your turbine performs at its peak.

Frequently Asked Questions

1. How does a gas turbine fuel water separator vessel work?

It separates water and impurities from fuel using gravity, centrifugal force, and filters, allowing clean fuel to flow to the turbine.

2. Why do gas turbines need fuel water separator vessels?

Gas turbines need them to prevent corrosion, blockages, and reduced efficiency caused by water or contaminants in the fuel.

3. How does a gas turbine fuel water separator vessel remove water?

Most separators use gravitational settling alongside coalescing elements. Small water droplets merge into bigger ones, then drop to the bottom of the vessel for removal.

4. Is a separate filter still necessary if I have a fuel water separator?

Often, yes. Each device has a distinct role. A fuel filter might catch solid particles, while the separator focuses on water. Both can work together to protect your turbine.

5. Should I replace filters more often in humid climates?

Absolutely. High humidity can introduce extra moisture into your fuel system. Replacing filters more frequently helps keep separation as effective as possible.

Key Takeaway

- Use a specialized separator to remove water from your turbine’s fuel, protecting equipment from corrosion and inefficient combustion.

- Regular maintenance, including inspections and filter replacements, helps keep your system healthy and boosts uptime.

- Automated drainage systems take out guesswork by detecting water levels and removing accumulated moisture without manual intervention.

- High-quality materials and proper design are vital for longevity, especially in demanding gas turbine applications.

- A well-maintained fuel water separator minimizes extra maintenance costs and helps you avoid downtime for repairs.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author