Table of Contents

ToggleNot all pipes are pressure vessels but some become one based on design and function. A pipe vessel is a pipe that stores pressurized fluids and meets specific criteria under ASME codes. This article breaks down the differences, when classification matters, and how to stay compliant in industrial systems.

The world of pressurized systems is vast, covering everything from boilers to tanks. But what about a pipe vessel can a pipe itself ever be considered a pressure vessel? This article breaks down that key question, exploring how pipes function in pressurized environments and under what conditions a pipe qualifies as a vessel. If you’re designing, inspecting, or working with pressure-rated systems, understanding the pipe vessel classification is crucial for safety, compliance, and performance.

Pipe: Think of pipes as highways for fluids, gases, or even solids. They move materials from Point A to Point B, forming the backbone of plumbing, oil, and gas industries. While pipes don’t contain pressure like vessels, they play a critical role in transporting pressurized contents.

Carry vs. Contain: Pipes focus on transporting fluids, whereas pressure vessels store and manage pressurized substances. When high-pressure containment is needed, pressure vessels take the lead.

Safety First: Pressure vessels feature built-in safety mechanisms like relief valves. Pipes, however, rely on their design and system setup to prevent failures and ensure smooth operation under pressure.

Routine Checks: Both need regular inspections, but the frequency and focus differ depending on their role and risk factors.

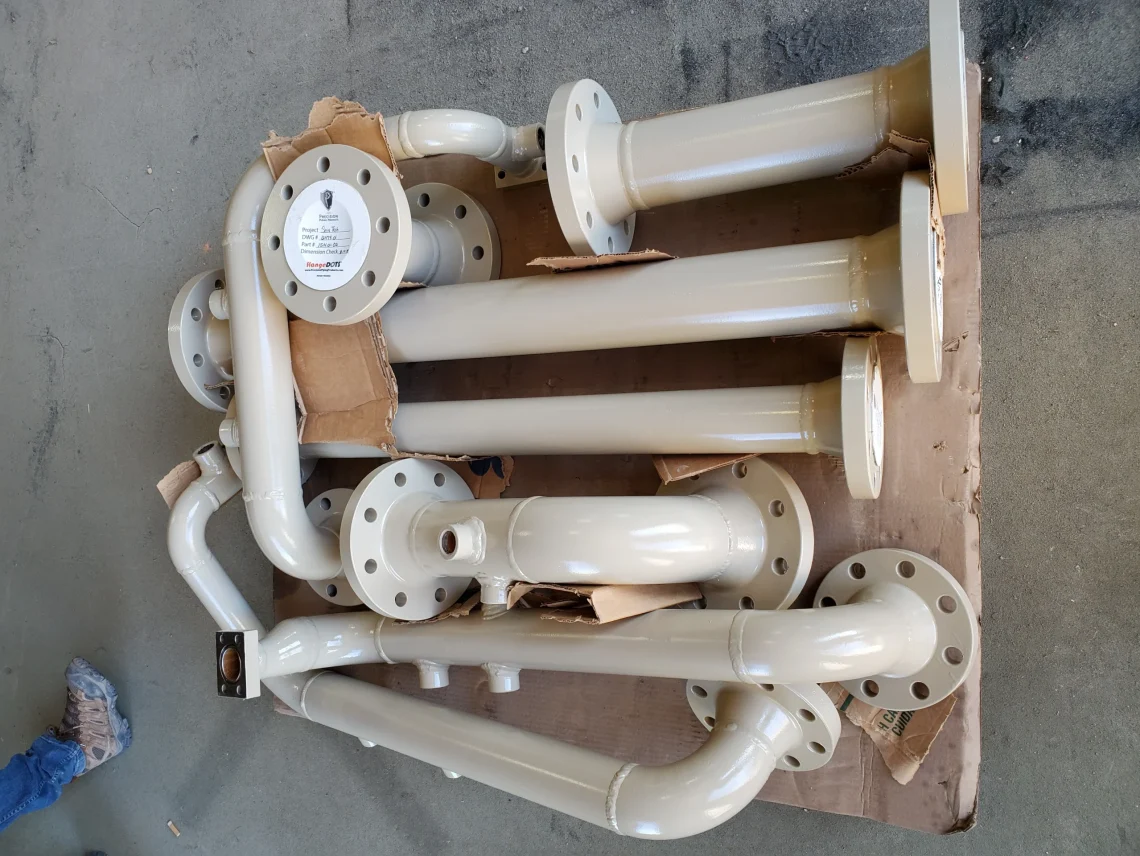

A pipe vessel refers to a pipe that, by design or function, must meet pressure vessel standards. This happens when the pipe’s purpose shifts from transporting fluids to containing pressurized substances often with closures, flanges, and capped ends.

For example, a pipe used to hold gas under pressure with no active flow is no longer just a transport channel it acts as a pressure vessel. In such cases, ASME Boiler and Pressure Vessel Code (Section VIII) typically applies, rather than just ASME B31.3 for piping.

Pipe vessels are common in high-risk applications like chemical reactors, gas separators, and certain sections of oil rigs.

Pipes and pressure vessels often share similar environments, especially in industries like oil and gas, where they manage high-pressure flows. Here’s a closer look at how they function in these demanding settings:

Pipes and pressure vessels play crucial roles in various industrial applications, collaborating to ensure efficient operations.

Pipes have evolved significantly, moving from early designs to modern innovations in materials and functionality to meet industrial demands.

Sustainability is a growing focus in pipe design, with efforts aimed at minimizing environmental impact while maintaining performance.

The financial aspect of using pipes in industrial applications plays a key role, balancing initial investments with ongoing maintenance.

Pipes, in their gig as the go-to transporters, are crucial, especially when they’re working under pressure. They might not always get the pressure vessel label, but their role in keeping things moving safely and efficiently is top-tier. As tech evolves and we get smarter about handling pressure, the journey of pipes is set to be one of constant innovation, safety, and efficiency.

Understanding the distinction between a pipe and a pressure vessel is more than technical semantics it has real-world implications for design, safety, and compliance. In certain applications, a pipe vessel must meet strict regulatory standards due to the pressure it contains. Recognizing when a pipe becomes a vessel ensures your systems are built safely and inspected correctly under ASME codes. As industries evolve, the role of pipe vessels will continue to grow in complexity and importance.

Whether you’re unsure how your pipe system fits ASME standards or need a custom-built pressure vessel, Red River is your trusted partner. From fabrication to code compliance, we help you get it right the first time.

Contact us today to talk with our engineers or request a quote tailored to your project.

Pipes and pressure vessels, while both integral in industrial applications, serve different purposes and are designed accordingly. Pipes are primarily designed for the transport of fluids (liquids and gases) from one location to another. Their design focuses on ensuring a smooth, efficient flow with minimal resistance. Pressure vessels, on the other hand, are designed to store fluids under pressure. They are constructed to withstand higher internal pressures and are subject to more stringent safety standards and regulations due to the potential risks involved.

Yes, a pipe system can be classified as a pressure vessel if it meets certain criteria. If a section of the piping system is used for storing fluids under pressure, rather than just conveying them, and if it includes features like closures, valves, and flanges that allow it to contain pressurized fluids, it may be considered a pressure vessel. The classification depends on the design, operating pressure, and the specific codes and standards applicable in the jurisdiction.

For pipes used in high-pressure applications, safety considerations include material selection, design pressure ratings, corrosion resistance, and regular maintenance and inspections. The material must be able to withstand the internal pressures and chemical properties of the fluid being transported. Additionally, the pipe should be designed with a pressure rating that exceeds the maximum operating pressure to provide a margin of safety. Regular inspections for signs of wear, corrosion, and damage are crucial to prevent leaks and failures.

Regulations and standards for pressure vessels can apply to pipes if those pipes function as part of a pressure-containing system. Standards such as the ASME Boiler and Pressure Vessel Code in the United States provide guidelines for the design, fabrication, inspection, and testing of pressure vessels, and certain sections of this code may be relevant to pipes used in pressurized systems. Compliance with these standards ensures safety and reliability in high-pressure applications.

Advancements in pipe design that contribute to their use in pressure vessel applications include the development of high-strength materials, improved fabrication techniques, and enhanced inspection and testing methods. High-strength materials allow pipes to withstand greater pressures, while advanced fabrication techniques, such as precision welding and seamless construction, improve the integrity and reliability of the pipe. Non-destructive testing methods, like ultrasonic testing, ensure the detection of flaws and weaknesses without damaging the pipe, contributing to safer operation in pressure vessel applications.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.