Gas turbines need fuel water separator vessels to remove moisture and impurities from fuel. This prevents corrosion, improves efficiency, and extends turbine lifespan.

Understanding Why Do Gas Turbines Need Fuel Water Separator Vessels

If you rely on gas turbines to power your facility or drive industrial processes, you might wonder,“why do gas turbines need fuel water separator vessels?” It’s a logical question because whenever water or impurities lurk in your fuel stream, your turbine’s performance can take a hit. According to multiple specialists (Red River Team), removing water and contaminants before they reach combustion chambers is crucial for safeguarding efficiency. Good news, ensuring you have the right fuel water separator vessel in place is often simpler and more cost-effective than you might imagine. Below, you’ll find out how these vessels work, why they matter, and how to select one that aligns with your power or manufacturing goals.

Why Do Gas Turbines Need Fuel Water Separator Vessels

Gas turbines require clean, moisture-free fuel to run efficiently and protect engine parts. Even small amounts of water can cause rust and corrosion in turbine blades, fuel injectors, and other components, leading to costly repairs and unexpected downtime. A quality fuel water separator vessel removes moisture and tiny contaminants before they reach the turbine, preventing damage and maintaining smooth combustion. Industry surveys show that preventing water-related corrosion can save facilities thousands daily by reducing outages. Ultimately, these separators help maximize turbine uptime and performance, making them a smart investment.

Preserving Turbine Efficiency

Tiny water droplets in fuel can disrupt combustion by dampening the flame and reducing the heat needed for optimal performance. Studies show that maintaining consistent, water-free fuel can improve turbine efficiency by 5 to 10%. Installing a fuel water separator vessel helps keep water out of the system, resulting in steadier power output, fewer misfires, and less frequent adjustments.

Extending Turbine Life

Corrosion caused by water-contaminated fuel is a major factor in turbine wear and premature failure. Water damages critical components, leading to more frequent and costly repairs. Fuel water separator vessels capture and drain water before it reaches sensitive engine parts, helping reduce the risk of corrosion and extending the turbine’s operational life.

How Fuel Water Separator Vessels Work

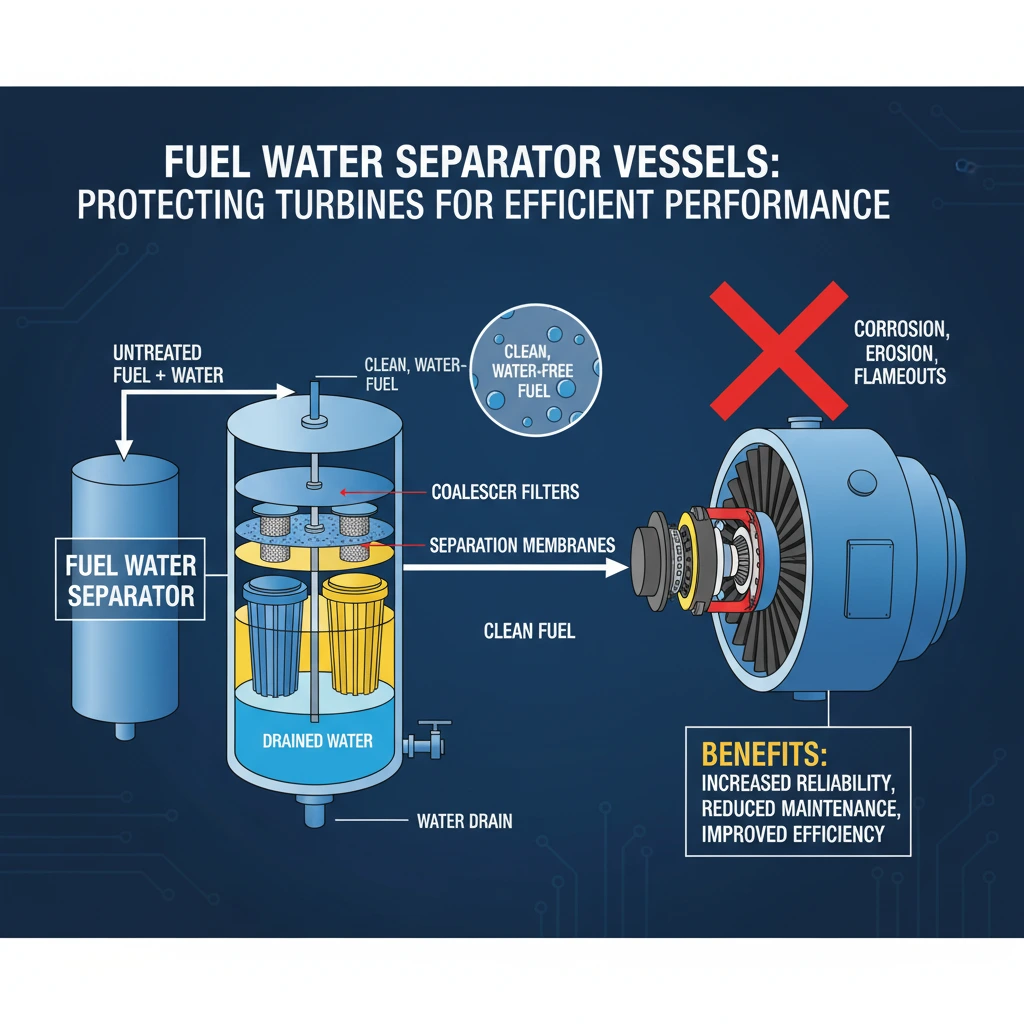

Fuel water separator vessels are built around clear physical principles, typically relying on gravity plus engineered filters. When fuel flows into the vessel, it slows long enough for water droplets (which are heavier) to settle at the bottom. Then, specialized media can help coalesce smaller droplets into bigger ones, making them easier to remove. The goal is to keep water far away from your turbine’s combustion area.

If you need a deeper explanation of separator configurations, you might explore how does an industrial fuel water separator vessel work. Generally speaking, the process goes like this:

- Fuel enters the vessel at a controlled rate.

- Inside, the fluid encounters coalescing media or filters that attract water droplets.

- As droplets collect, they become heavier and sink, gathering in a sump or drain section.

- Cleaned fuel exits the vessel, carrying minimal to no water content.

Collaborating with Reliable Partners

Sourcing the right separator vessel for your setup is much easier when you have an experienced partner. Industry teams like Red River Team handle the design and fabrication of these vessels for major oil and gas providers around the world. They offer prefabricated solutions that can reduce costs by up to 15%, thanks to decreased on-site labor, streamlined shipping, and minimal construction waste. Teaming up with a proven specialist also gives you assurance that your finished separator will align with recognized standards and perform reliably under demanding conditions.

Choosing the Right Fuel Water Separator

Not every gas turbine environment is the same. Different fuels, flow capacities, and operating pressures result in different separator requirements. For instance, if you run a large-scale power plant with high flow volume, you’ll need a robust, multi-phase separator to handle rapid throughput. Smaller or mid-size facilities might opt for simpler filter-based vessels. Either way, it’s important to check that the design meets recognized certifications, such as the American Society of Mechanical Engineers (ASME) standards for pressure vessels.

If you’re curious about structural guidelines, see why must separators be asme pressure vessels. For a quick glance at key selection factors, consult the table below:

| Factor | Consideration |

| Flow Rate | High volume might require a larger or multi-stage unit. |

| Operating Pressure | Choose a vessel with a rated pressure above your turbine’s maximum. |

| Fuel Composition | Diesel, renewable natural gas, or heavier fuels each demand unique vessel features. |

| Desired Maintenance | Look for easily replaceable filters or casings if you want minimal downtime. |

| Compliance Standards | ASME and other certifications ensure safe, reliable performance. |

When evaluating your options, think about how often you’ll need to maintain the vessel, how it will integrate into your existing system, and what kind of lead times you’re willing to manage. In many cases, a prefabricated separator is delivered ready to integrate, simplifying your overall project schedule.

Install and Maintain for Peak Performance

Even the best vessel fails if it’s placed incorrectly in the fuel supply line. Typically, you want your fuel water separator upstream of the final fuel pump but downstream from any bulk filtering units. This layout ensures your turbine receives the cleanest possible fuel. If you’re new to installing these systems, consider a professional assessment to pinpoint the ideal location.

Besides correct placement, you’ll need a solid maintenance plan to keep the vessel effective. Consistent, scheduled tasks not only prevent water buildup, but also allow you to spot early warnings of corrosion or filter clogs. According to Red River, regular upkeep can significantly extend the operational lifespan of industrial equipment. Here are some tips:

- Check water levels in the separator weekly.

- Drain the sump or water reservoir before it rises above recommended limits.

- Swap out filter elements based on the manufacturer’s guidelines.

- Monitor differential pressure to detect clogging.

- Keep detailed logs of part replacements to anticipate future maintenance costs.

Good news, these steps are straightforward, and once you adopt a routine, you’ll find that your turbine remains more stable and efficient in its daily operations.

Why Do Gas Turbines Need Fuel Water Separator Vessels for Long-Term Protection

The bottom line: turbines need moisture-free fuel to perform at their best. Why do gas turbines need fuel water separator vessels? To protect equipment, preserve efficiency, and extend life. By investing in a compliant, prefabricated vessel, you reduce downtime, lower costs, and secure safer operations.

Partner with Red River for Reliable Separator Vessels

Red River delivers custom-engineered, ASME-compliant vessels designed for your operation. With prefabrication and proven expertise, we ensure efficiency, safety, and durability in every project. Contact Red River to discuss your fuel water separator needs and discover how we can help protect your turbine and maximize uptime.

Frequently Asked Questions

1. What is a gas turbine fuel water separator vessel?

A gas turbine fuel water separator vessel is a device that removes water and contaminants from fuel before it reaches the turbine.

2. How does a gas turbine fuel water separator vessel work?

It separates water and impurities from fuel using gravity, centrifugal force, and filters, allowing clean fuel to flow to the turbine.

3. What exactly is removed by a fuel water separator vessel?

These vessels remove water, sediments, and other impurities from your fuel, helping protect your turbine’s internal components from corrosion.

4. Is a fuel water separator vessel necessary for all gas turbine setups?

Nearly all gas turbine installations benefit from separating water and impurities to avoid oxidation and ensure stable combustion.

5. How often should I drain or maintain the vessel?

This depends on your usage and fuel quality, but a weekly check is a good start. Always follow the manufacturer’s manual for precise intervals.

Key Takeaways

- Consistent fuel quality is vital for maximizing gas turbine performance and protecting components.

- A fuel water separator vessel actively removes water and other impurities, preventing corrosion and reducing downtime.

- Proper system design and placement, typically upstream of your final pump, streamline maintenance and improve efficiency.

- Prefabrication can cut costs and timelines, thanks to reduced labor hours and fewer logistical barriers.

- Routine checks, including draining, filter changes, and pressure monitoring, will keep your turbine running reliably for years to come.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author