Understanding the Basics of Water-Oil Separation

[ez-toc] Water-oil separation is vital for preventing equipment failure, reducing maintenance costs, and meeting environmental regulations. Mechanical, chemical, and advanced technologies like membrane or ultrasonic filtration each offer unique benefits depending on contamination levels, volume, and purity needs. Choosing the right method and maintaining the system properly ensures long-term operational efficiency and compliance. Understanding the […]

Understanding Pressure Drop in Coalescing Filters

Pressure drop in coalescing filters directly affects system efficiency and energy costs. A clean filter should show a pressure drop between 0.5–1.5 psi, but this can rise due to flow rate, contamination, or poor filter selection. Monitoring ΔP with gauges and following a maintenance schedule can prevent system failures, reduce energy consumption by up to […]

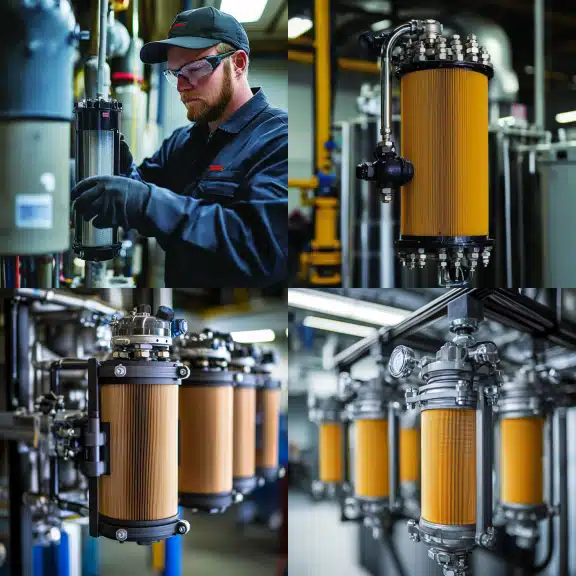

Mastering Coalescing Filters: A Comprehensive Guide

Coalescing filters are essential in industrial settings to purify gas and air by removing liquids and particulates. Widely used in oil & gas, compressed air systems, and cleanroom industries, these filters improve equipment lifespan, reduce maintenance costs, and ensure high product quality. Red River provides tailored coalescing filter solutions, helping clients meet strict performance and […]

Signs Your Air Filter Needs Replacing

Signs Your Air Filter Needs Replacing Your air filter plays a critical role in keeping your systems efficient, clean, and safe. When it becomes clogged, airflow drops, allergens increase, and dust accumulates quickly. These issues signal that your filter is no longer performing effectively. Replacing your filter on time improves performance, protects equipment, and maintains […]

Coalescing Filters Efficiency: Understanding Performance in Industrial Systems

Coalescing Filters Efficiency: Understanding Performance in Industrial Systems Coalescing Filters Efficiency is a key factor in achieving clean, reliable, and optimized industrial operations. These filters remove liquid aerosols and contaminants that compromise system performance. Understanding how they work, what affects their efficiency, and how they are maintained helps maximize overall system reliability. By choosing the […]

Difference Between Coalescing Filter and Water Separator

Difference Between Coalescing Filter and Water Separator Understanding the difference between coalescing filter and water separator is essential for maintaining system efficiency, equipment protection, and clean operation. While both components remove contaminants, they work in different ways and target different impurities. Coalescing filters handle fine aerosols and microscopic particles, while water separators remove bulk liquids. […]

Coalescers in Filtration Systems

Coalescers in Filtration Systems Coalescers in filtration systems are vital for removing contaminants from gas and liquid streams efficiently. They merge small droplets into larger ones for easier separation, improving system performance and longevity. Understanding how coalescers work helps industries optimize filtration, reduce maintenance costs, and ensure compliance with Pressure Vessel Safety Standards and Compliance. […]

Coalescing Filters Guide for Enhancing Industrial Filtration Efficiency

Coalescing Filters Guide for Enhancing Industrial Filtration Efficiency Coalescing filters guide industrial operators on how to effectively remove liquid contaminants, oil mist, and particulates from air and gas streams. These filters improve system performance, extend equipment lifespan, and reduce operational costs. Proper maintenance and inspection ensure they operate efficiently while complying with pressure vessel safety […]

Coalescing Filter Maintenance: Essential Practices for Optimizing Filtration Performance

Coalescing Filter Maintenance: Essential Practices for Optimizing Filtration Performance Coalescing filter maintenance is crucial for ensuring clean, efficient, and dependable system performance. When filters are properly maintained, they support better separation efficiency, reduced contamination, and longer equipment life. Regular inspection and cleaning help prevent premature failure and ensure systems operate at peak performance. Consistent upkeep […]

Difference Between a Scrubber and a Separator: A Comprehensive Guide

Difference Between a Scrubber and a Separator: A Comprehensive Guide Understanding the difference between a scrubber and a separator is essential for industrial efficiency and compliance. Scrubbers remove pollutants from gas streams, while separators divide different phases such as gas, liquid, or solids. Proper selection, maintenance, and operation ensure optimal system performance and adherence to […]