How High-Pressure Welding Technology Is Evolving to Meet Demands

High-pressure welding is rapidly evolving with automation, real-time monitoring, AI, and advanced material-specific techniques, improving safety, consistency, and efficiency in pressure vessel fabrication. Digital integration, AR/VR training, and predictive technologies are transforming quality control from defect detection to prevention while addressing skilled labor and regulatory challenges. The Changing Landscape of High-Pressure Welding Requirements In the […]

Challenges in Dissimilar Metal Welding Pressure Vessels

Dissimilar metal welding in pressure vessels combines different metals to optimize performance and corrosion resistance but introduces challenges like thermal expansion mismatch, carbon migration, galvanic corrosion, and brittle phase formation. Success relies on proper filler selection, specialized welding techniques, thorough testing, and ongoing monitoring to ensure long-term safety and reliability. Understanding Dissimilar Metal Welding Pressure […]

Robotic Welding Pressure Vessels Fabrication: Future or Fad?

The Evolution of Welding Technology in Pressure Vessel Manufacturing In an industry where precision means safety and quality equates to longevity, pressure vessel manufacturing stands at a technological crossroads. The integration of robotic welding pressure vessels has sparked debate among fabricators, engineers, and industry leaders. As manufacturers face increasing demands for higher productivity, consistent quality, […]

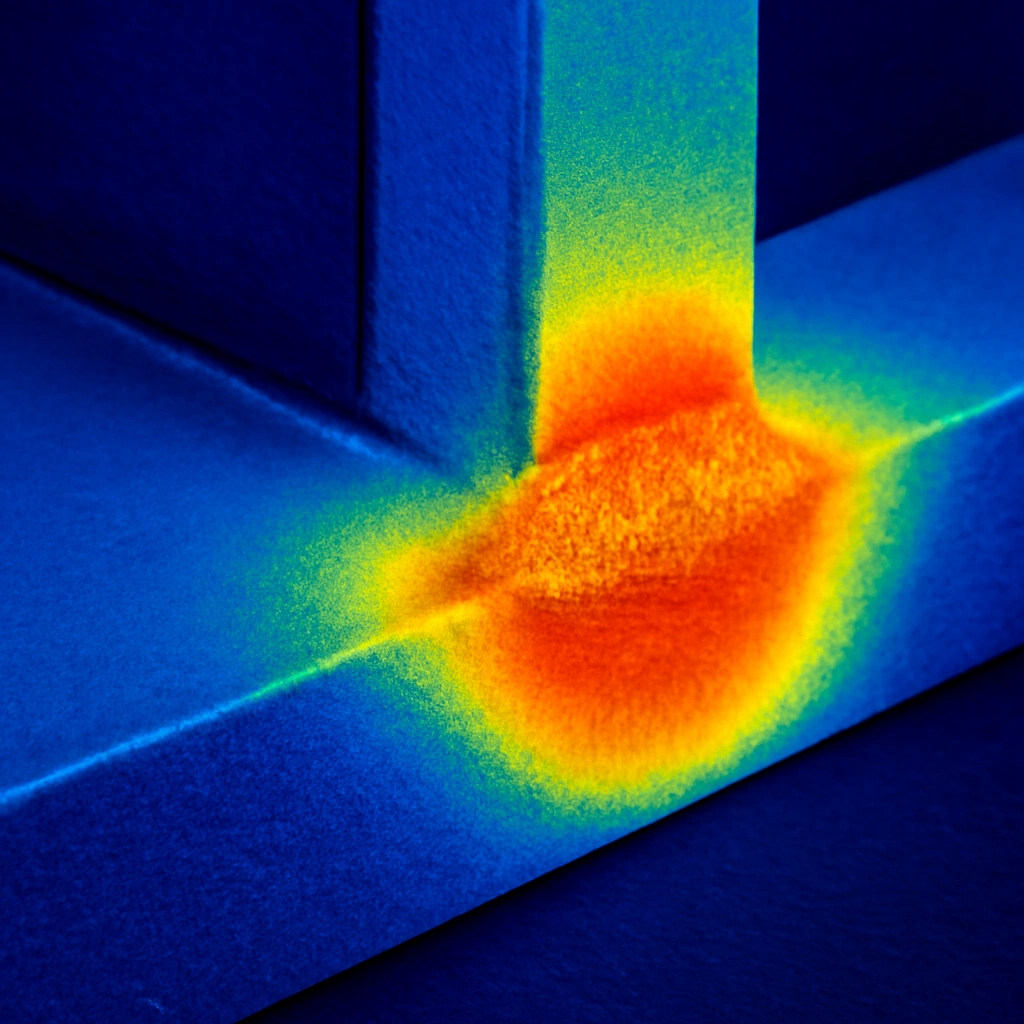

Understanding Post-Weld Heat Treatment: A Critical Process for Structural Integrity

What is Post-Weld Heat Treatment and Why It Matters Post-weld heat treatment (PWHT) stands as one of the most crucial yet often overlooked processes in welding fabrication. For industries relying on pressure vessels, piping systems, and critical structural components, PWHT can mean the difference between decades of reliable service and premature catastrophic failure. This controlled […]

The Link Between Weld Quality Pressure Vessels Lifespan

Understanding the Critical Role of Weld Quality Pressure Vessels When it comes to industrial equipment, pressure vessels stand at the forefront of critical infrastructure. These essential components operate under significant stress, containing gases and liquids at pressures dramatically different from ambient conditions. While many factors contribute to vessel performance, none is more fundamental than weld […]

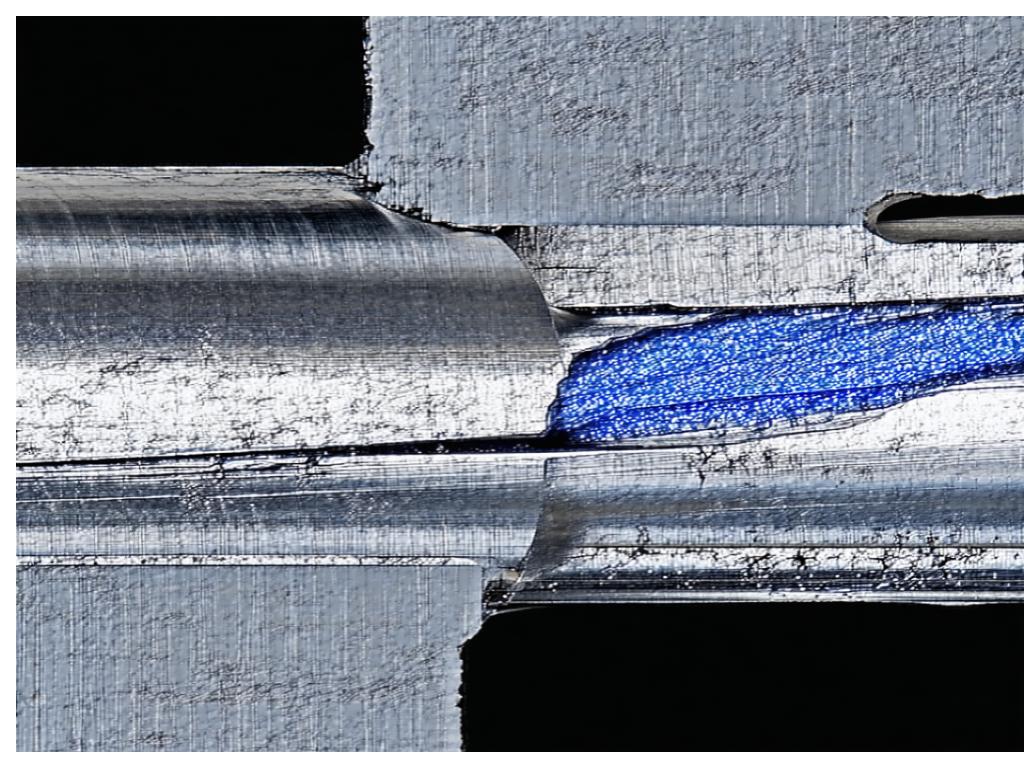

Heat-Affected Zone Welding: Understanding the Critical Transition Region

What Is a Heat-Affected Zone Welding? When it comes to welding quality and structural integrity, what you can’t see is often what matters most. Behind every weld lies a complex region that dramatically influences joint performance – the heat-affected zone. This crucial but often overlooked area determines whether a welded joint will perform reliably or […]

Why Pressure Vessel Welders Certification Is Crucial for Safety

Understanding Pressure Vessel Welders Certification Standards and Risks Pressure vessels are critical components in numerous industries, containing liquids and gases under pressure that can pose significant safety risks if not properly constructed. The welding work performed on these vessels is not just another manufacturing task—it’s a highly specialized skill that directly impacts safety, compliance, and […]

The Role of Non-Destructive Testing Welding Inspection in Manufacturing Quality

Understanding Non-Destructive Testing Welding Inspection in Modern Fabrication In the world of industrial fabrication and manufacturing, weld quality directly impacts safety, operational reliability, and equipment lifespan. While a weld may appear flawless on the surface, internal defects can compromise structural integrity and lead to catastrophic failures. Non-destructive testing welding inspection provides essential verification methods that […]

Vessel Welding Joint Preparation for Optimal Strength

The Critical Foundation: Understanding Joint Preparation Fundamentals Proper welding techniques are the backbone of pressure vessel integrity. When it comes to fabricating industrial vessels that must withstand extreme pressures and harsh environments, two factors stand out as critical determinants of safety and longevity: vessel welding, joint preparation and positioning. These foundational elements often receive less […]

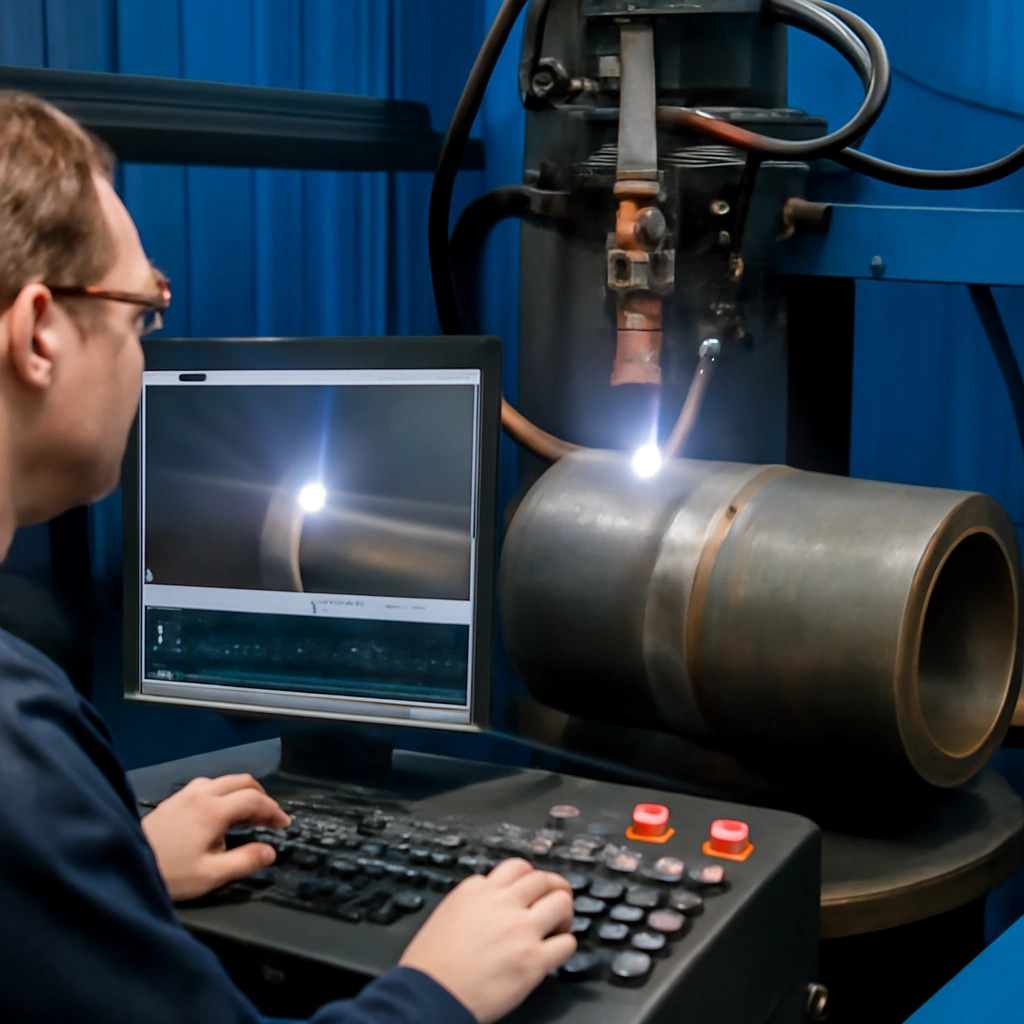

Automated Vessel Welding in Modern Manufacturing

The Evolution of Automated Vessel Welding In today’s competitive manufacturing landscape, pressure vessel fabrication has undergone a revolutionary transformation through the adoption of automated vessel welding. These advanced systems have redefined industry standards, creating vessels that are not only safer and more reliable but also produced with unprecedented efficiency. This article explores how automated vessel […]