High-pressure welding is rapidly evolving with automation, real-time monitoring, AI, and advanced material-specific techniques, improving safety, consistency, and efficiency in pressure vessel fabrication. Digital integration, AR/VR training, and predictive technologies are transforming quality control from defect detection to prevention while addressing skilled labor and regulatory challenges.

The Changing Landscape of High-Pressure Welding Requirements

In the world of pressure vessel manufacturing, high-pressure welding technology is central to safety, reliability, and performance. As industrial demands push the limits of materials and designs, welding innovations are evolving rapidly. From advanced automation to sophisticated monitoring systems, these developments are transforming how high-pressure components are fabricated while maintaining the stringent standards critical for safety and performance.

Industry Trends Driving Welding Innovation

The landscape for high-pressure welding is shifting due to multiple converging factors. Energy transition projects require vessels capable of safely containing hydrogen, carbon dioxide, and other gases at unprecedented pressures. Offshore oil and gas operations explore deeper waters under extreme conditions, while chemical processing industries demand increased durability with reduced maintenance intervals. Companies are increasingly seeking prefabrication solutions and modular skids to streamline production under these evolving demands.

Increasing Material Complexity in Pressure Applications

Modern pressure vessels often use specialized materials selected for extreme performance, including high-strength low-alloy steels, duplex stainless steels, and nickel-based alloys. Each material presents unique welding challenges. These advanced materials typically have narrow processing windows and may be prone to hydrogen cracking, require precise heat control, or develop undesirable microstructures if welding parameters are not strictly maintained. Understanding the ideal material for pressure vessel fabrication is now more critical than ever.

Stricter Quality and Safety Standards

Regulatory requirements for pressure-containing equipment continue to tighten due to the potential consequences of failure. ASME certification and compliance with pressure vessel codes now demand detailed documentation, qualification testing, and quality verification. Modern welding systems are designed to support these requirements, with automated parameter logging and integrated inspection capabilities ensuring compliance throughout the vessel’s service life.

Breakthrough Technologies Transforming Pressure Vessel Fabrication

Advanced Automated and Robotic Welding Systems

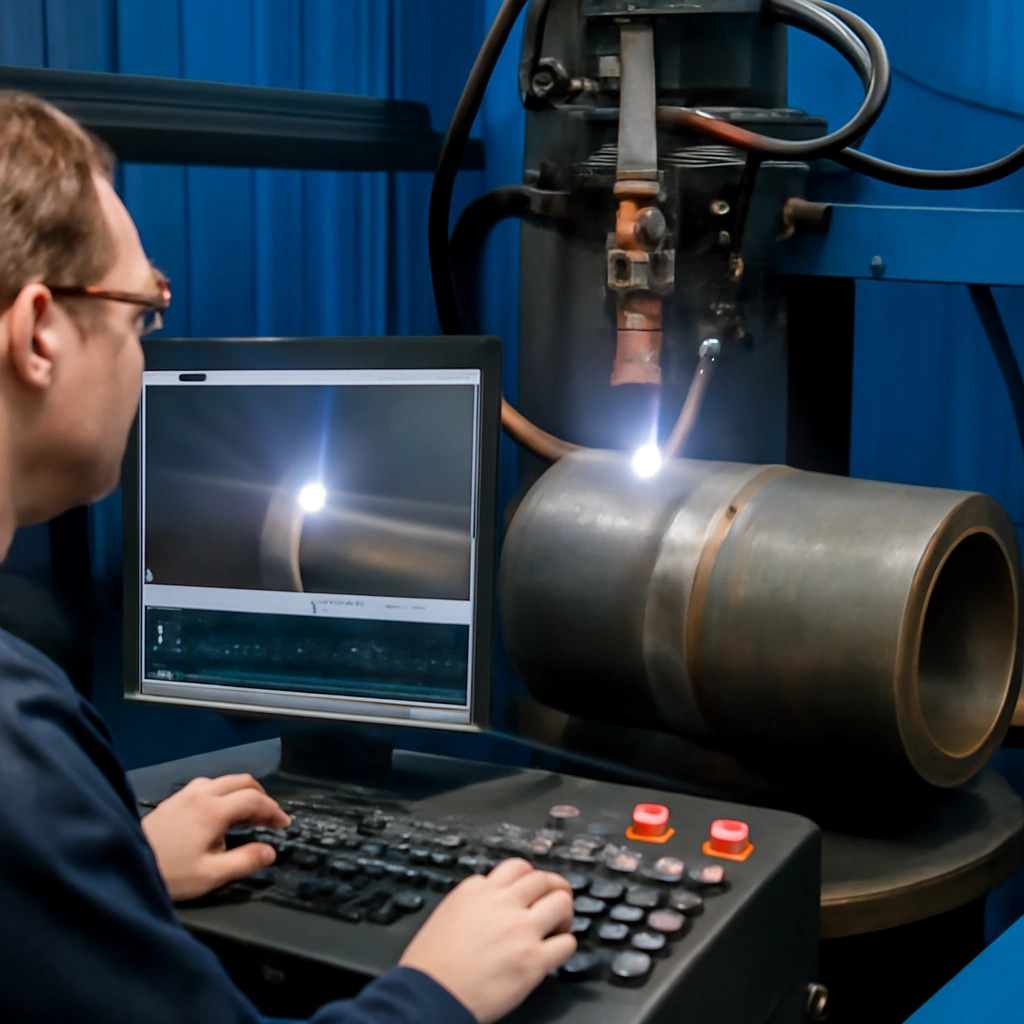

Perhaps the most visible evolution in high-pressure welding technology is the increasing role of automation and robotics. Modern systems range from semi-automated orbital welders for pipe connections to fully robotic cells capable of completing complex pressure vessel welds with minimal human intervention.

These systems bring several advantages to high-pressure applications:

- Consistent travel speeds and torch angles across operators

- Precise parameter control maintaining optimal welding conditions

- Sustained quality over long welding operations

- Comprehensive data logging documenting every weld

These advancements support fabrication of complex pressure vessels with minimal human error.

Precision Monitoring and Real-Time Quality Control

High-pressure welding now incorporates sophisticated real-time monitoring systems tracking voltage, amperage, wire feed speed, and gas flow hundreds of times per second. Unlike traditional post-weld inspections, these systems prevent defects before they occur, improving both quality and efficiency.

Hybrid and Multi-Process Welding Solutions

Hybrid and multi-process systems combine the strengths of various welding methods, enabling optimization at each stage. For thick-walled high-pressure vessels, these approaches increase productivity without compromising safety or structural integrity.

Narrow Gap Welding Techniques for Thick-Walled Components

Thick-walled vessels require enormous amounts of filler metal with traditional V-groove joints. Narrow gap welding techniques reduce filler use and welding time, offering both efficiency and high-quality results.

Digital Integration and Industry 4.0 in Welding Processes

Data-Driven Parameter Optimization

Advanced welding processes leverage data-driven optimization to replace trial-and-error methods. The result is consistent, high-quality welding critical for pressure applications.

AR/VR Applications in Welder Training and Assistance

Augmented reality (AR) and virtual reality (VR) are addressing skilled welder shortages. AR helmets project optimal torch angle, travel speed, and position in real time, while VR systems allow apprentices to practice complex welds safely.

AI-Powered Defect Prediction and Prevention

Artificial intelligence analyzes process data to predict potential defects before they occur, shifting focus from defect detection to defect prevention. This is particularly vital for critical pressure components.

Material-Specific Advancements in High-Pressure Welding

New Solutions for High-Strength Alloy Welding

Pressure vessels increasingly use high-strength alloys for greater pressures at lower weights. Specialized power sources with waveform control manage heat input and cooling rates to maintain mechanical properties.

Managing Heat Input in Critical Applications

Heat input control has become increasingly sophisticated as materials with narrow processing windows become more common in pressure vessel applications. Modern power sources offer pulsing capabilities, advanced waveform control, and precise energy regulation that would have been impossible with previous generations of equipment.

Addressing Hydrogen Sensitivity in Modern Materials

Hydrogen-induced cracking presents a significant risk in many high-strength materials used for pressure applications. Advanced welding technologies address this challenge through multiple approaches, including specialized low-hydrogen processes, carefully controlled preheat and interpass temperature monitoring, and automated heat management systems.

The Future of High-Pressure Welding

The evolution of high-pressure welding technology represents a critical advancement in industrial fabrication. Digital technologies, automation, advanced materials science, and sophisticated monitoring systems are transforming how pressure-containing components are manufactured to meet increasingly demanding requirements.

The future lies in effectively integrating cutting-edge technology with human expertise. While automation and AI enhance consistency, skilled welding professionals remain essential, particularly for complex applications with unfamiliar alloys. The most successful manufacturers will blend technological capabilities with deep metallurgical understanding and code compliance expertise.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. How is automation changing the field of high-pressure welding?

Automation in high-pressure welding has evolved beyond simple mechanized systems to include adaptive technologies that can respond to changing conditions. Modern systems incorporate sensors that monitor joint alignment, adjust parameters based on material thickness, and maintain consistent quality regardless of position or orientation.

2. What quality control technologies are most important for high-pressure applications?

Real-time monitoring systems that track actual welding parameters have become essential for high-pressure applications. These systems compare actual voltage, amperage, travel speed, and other critical variables against qualified ranges hundreds of times per second.

3. How are modern welding technologies addressing hydrogen-induced cracking?

Modern welding systems address hydrogen-induced cracking through multi-faceted approaches. Advanced power sources with precise heat control maintain optimal thermal profiles that allow hydrogen to diffuse out of welds before cooling.

4. What training is required for technicians working with advanced welding systems?

Technicians working with advanced welding systems require a blend of traditional welding knowledge and modern technical skills. Training typically includes fundamentals of welding metallurgy, practical hands-on experience with conventional processes, and specialized training on digital interfaces, programming, and troubleshooting.

5. How do narrow gap welding techniques benefit pressure vessel fabrication?

Narrow gap welding delivers substantial benefits for thick-walled pressure vessels by reducing both filler metal consumption and welding time. By decreasing the included angle of joint preparations from traditional 60° or more to as little as 5°, these techniques can reduce weld metal volume by up to 80% in thick sections.

6. What role does digital documentation play in code-compliant pressure welding?

Digital documentation has become essential for code-compliant pressure welding as regulatory requirements increase in stringency. Modern welding systems automatically record actual parameters for every inch of weld, creating complete traceability throughout fabrication.

Key Takeaways

- New technologies are making high-pressure welding safer and more reliable through automation, real-time monitoring, and process control

- Digital integration is transforming quality control from defect detection to defect prevention

- Advanced training methods utilizing AR/VR are addressing skilled labor shortages

- Material-specific solutions are enabling the use of more specialized alloys that can withstand extreme pressure conditions

- Automation and monitoring systems are increasing consistency while generating comprehensive documentation for code compliance

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author