Managing martensite formation in quenched-and-tempered steels requires precise control of composition, cooling rates, and tempering. Properly balancing these factors ensures the desired combination of hardness, strength, and toughness in steel components.

Comprehensive Guide in Managing Martensite Formation

Effectively managing martensite formation is critical for manufacturers working with quenched-and-tempered steels. Martensite, a hard and brittle microstructural phase, forms during rapid cooling and strongly influences the final mechanical properties of steel components. Understanding how to control martensite formation requires knowledge of phase transformations, cooling rates, alloy composition, and subsequent heat treatments like tempering.

For more insights into metal behavior and fabrication, explore our guide to metal fabrication and metal fabrications services.

The Science Behind Martensite Formation

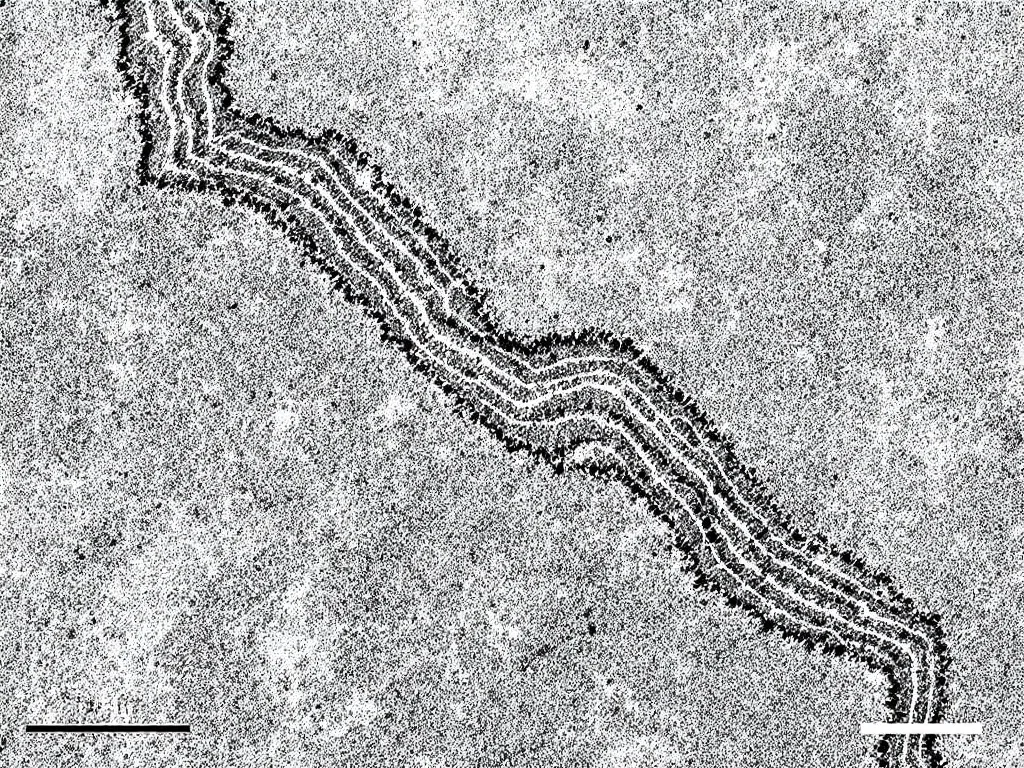

Martensite is a metastable phase that develops when austenite rapidly cools below a critical temperature. Its formation follows a diffusionless mechanism, meaning carbon atoms are trapped in a distorted body-centered tetragonal (BCT) structure. This produces the needle-like or lath microstructures that are characteristic of martensite, giving it high hardness but low ductility.

Understanding steel microstructures is essential for quality assurance in custom pressure tank manufacturing and other precision applications. Learn more about the science of metallurgical processes on our blog.

Critical Factors in Managing Martensite Formation

Carbon Content and Alloying Elements

Carbon content is pivotal in determining how much martensite forms during quenching. Typical quenched-and-tempered steels contain 0.25–0.55% carbon, with each 0.1% increase potentially raising hardness by ~4 HRC.

Alloying elements like manganese, chromium, molybdenum, and nickel impact martensite by:

- Increasing hardenability

- Modifying martensite start (Ms) and finish (Mf) temperatures

- Affecting stability during tempering

For a deeper understanding of alloy effects, see our capabilities and solutions pages.

Quenching Media and Cooling Rates

Managing martensite formation depends heavily on selecting appropriate quenching media. Common options include:

- Water: Provides rapid cooling but increases distortion and cracking risk

- Oil: Moderates cooling rate, reducing distortion while ensuring sufficient hardness

- Polymer solutions: Offers customizable cooling rates between water and oil

- Salt baths: Enables isothermal quenching for specialized applications

The ideal cooling rate must be fast enough to avoid undesirable transformations (like pearlite or bainite formation) while minimizing internal stresses. According to research from Materials Science International, cooling rates between 50-100°C/second are optimal for many medium-carbon steels when managing martensite formation.

Tempering: The Essential Follow-up Process

After managing martensite formation through quenching, tempering becomes essential to reduce brittleness while maintaining adequate strength. This process involves reheating the martensite to temperatures between 150-650°C, allowing:

- Carbon diffusion out of supersaturated solution

- Stress relief within the martensite structure

- Formation of carbide precipitates

- Increased toughness with controlled strength reduction

The tempering temperature and duration directly influence the final properties. For example, tempering at 200°C might yield a hardness of 58-60 HRC, while 600°C tempering could reduce it to 30-35 HRC while dramatically improving toughness.

At Red River, our heat treatment services employ precise tempering protocols to achieve optimal property combinations in quenched-and-tempered components.

Mastering Martensite Formation Management

Managing martensite formation in quenched-and-tempered steels requires a delicate balance between composition, cooling rate, and subsequent tempering. By understanding the science behind martensite transformation and implementing controlled processes, manufacturers can achieve the desired combination of hardness, strength, and toughness in their steel components. The ability to predict and control martensite characteristics enables the production of high-performance parts for demanding applications across numerous industries.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. What is martensite and why is it important in steel?

Martensite is a hard, metastable microstructural constituent in steel formed during rapid cooling. It’s important because it provides the high hardness and strength necessary for many engineering applications, serving as the foundation for subsequent tempering treatments.

2. How does carbon content affect martensite formation?

Carbon content directly impacts martensite hardness and volume fraction. Higher carbon percentages increase martensite hardness but also elevate brittleness and cracking susceptibility, making carbon content a critical variable when managing martensite formation.

3. What are the signs of incomplete martensite formation?

Incomplete martensite formation manifests as lower-than-expected hardness, inconsistent microstructure with retained austenite or other transformation products, and suboptimal mechanical properties. Metallographic examination typically reveals a mixed microstructure rather than the uniform needle-like pattern of complete martensite.

4. Can martensite formation be reversed?

Yes, martensite formation can be reversed through processes like austenitizing (heating above critical temperature) followed by controlled cooling. This allows for reworking components with undesirable martensite characteristics.

5. How does section size affect martensite formation in steel components?

Larger section sizes experience slower cooling rates at their cores, potentially resulting in non-martensitic microstructures in these regions. This “hardenability limitation” requires adjustments to alloy content or quenching severity when managing martensite formation in thick sections.

6. What tempering temperature is recommended for optimal toughness?

For optimal toughness while maintaining reasonable strength, tempering temperatures between 400-550°C are typically recommended. The exact temperature depends on the specific steel grade and application requirements.

Key Takeaways

- Successful martensite formation depends on rapid cooling to prevent diffusion-controlled transformations

- Carbon content is the primary determinant of martensite hardness and brittleness

- Alloying elements enhance hardenability and modify martensite characteristics

- Quenching medium selection balances cooling rate needs against distortion/cracking risks

- Tempering is essential for developing useful mechanical properties from the as-quenched martensite

- Proper process control requires understanding both the science and practical aspects of managing martensite formation

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author