Fatigue failure analysis studies how repeated stress causes microscopic cracks that grow and eventually cause sudden material failure. It’s critical for preventing costly breakdowns and accidents in industries like energy, agriculture, and chemical processing by identifying stress hotspots and early damage. Combining lab tests, inspections, and simulations helps extend equipment life and improve safety.

Understanding What is Fatigue Failure Analysis and Why it Matters

Many industries deal with materials under repeated stress that cause tiny cracks to grow into major failures. Fatigue failure analysis helps spot these early signs, preventing costly downtime and accidents. Up to 90% of metal failures stem from fatigue, making this analysis essential for safety and reliability.

What is fatigue Failure Analysis

Fatigue failure analysis studies how materials break from repeated loading or vibrations. Microscopic cracks form and grow with each stress cycle, eventually causing sudden fractures like bending a paper clip repeatedly until it snaps.

The Concept Behind Cracks

Materials don’t fail immediately but develop tiny cracks that slowly spread. Advanced simulations can identify stress hotspots where cracks may form. Sometimes parts endure thousands of cycles with no visible damage until a crack reaches a critical size and fails suddenly.

Real-world Example

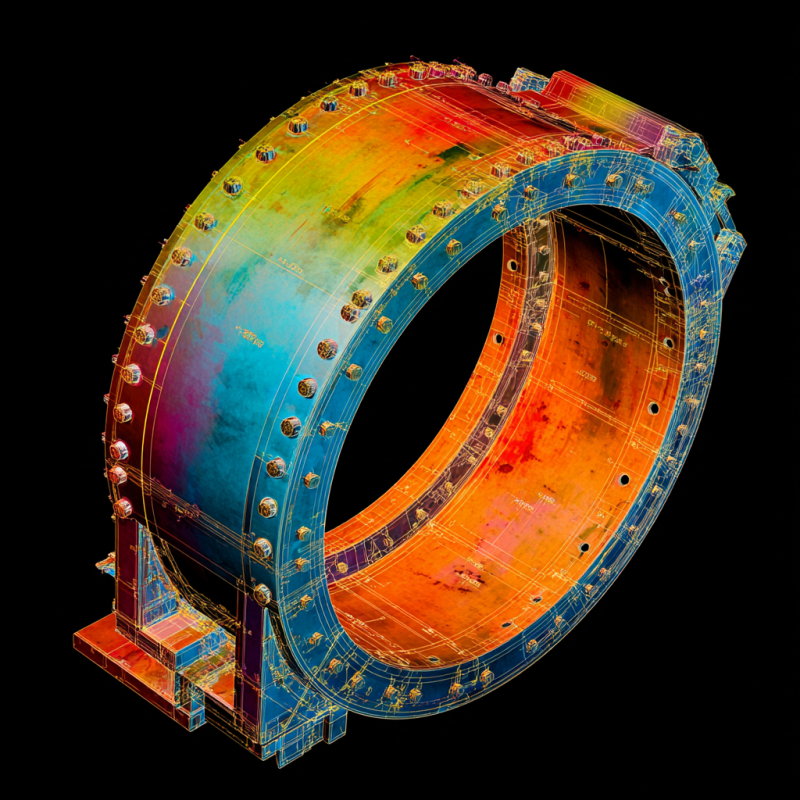

Pressure vessels face repeated pressure changes that cause tiny stress variations, weakening welds and seams over time. Early fatigue failure analysis helps detect damage before costly or dangerous failures occur, giving you better insight into your equipment’s condition.

If you want to explore more about evaluating such systems, you may also find it useful to visit pressure vessel failure analysis for a specialized look at potential failure modes.

Identify Key Stress Factors

Certain triggers accelerate fatigue more than others. Identifying those triggers will help you manage risks and extend your equipment’s life.

Cyclic Loading and Pressure Swings

When a part is repeatedly loaded, unloaded, and reloaded, the stress in the material fluctuates. Commonly, these loads are well within a “safe” range if you only consider a single application of force. But under repeated cycles, what was once a mild stress can start forming cracks. For instance, consider an industrial pump that turns on and off dozens of times a day. Each startup is a surge in stress. Over months or years, fatigue damage accumulates.

Temperature Fluctuations

Constantly shifting from hot to cold can also create expansions and contractions in metal or composite structures. A pipe transferring hot liquids might expand, while the cooler surrounding air makes the surface contract. This mismatch leads to thermal stress cycles. Routine shifts from night to day or from idle to active can produce thousands of “mini-cycles” each year, boosting the potential for fatigue failure.

How Industries Use It

You’re not alone in wondering how to spot and prevent cyclical cracks. Many sectors have turned fatigue failure analysis into a standard practice.

Energy Production

Power plants (fossil, nuclear, or renewables) often run turbines, boilers, or reactors that experience significant cyclical loading. Parts such as turbine blades, rotor shafts, and pressure boundaries see loads that fluctuate during startup, shutdown, and load adjustments. Fatigue testing and analysis keep everything performing safely. According to one 2024 engineering report, 35% of unexpected breakdowns in rotating equipment stem from fatigue growth that remained unnoticed until major damage was done.

Agriculture and Chemical Sectors

In agriculture, equipment like mixers, pumps, and rotating shafts face constant stress from vibration and repetitive motion. In chemical plants, piping and chambers endure repeated heating, cooling, and pressurization cycles. Without fatigue failure analysis, cracks often go unnoticed until a serious leak or break occurs. Both sectors benefit from combining regular inspections with structural analysis to catch early signs of fatigue. For broader insight, see material failure analysis, which covers additional testing methods that support fatigue investigations.

Recognize Warning Signs

Spotting early fatigue cracks can save you from unexpected shutdowns. Fortunately, materials often display subtle hints long before they fail completely.

Visual Cracks or Micro-fractures

The classic sign of an impending fatigue issue is a series of small cracks along weld lines, edges, or high-stress zones in your equipment. In many cases, these cracks appear in a pattern that follows the direction of stress. You might need magnification or advanced imaging to detect them. Sometimes, partial penetration in a weld can propagate outward, so you only see a hairline fracture on the surface. That’s your cue to investigate more deeply.

Material Changes Over Time

A subtle sign might be a change in how your equipment sounds or vibrates. Components under cyclic stress can gradually deform, slightly changing your machine’s alignment. This leads to a new hum, more pronounced vibration, or slight misalignment in bearings or shafts. You might also see surface discoloration where friction or repeated stress has increased local heat. Ignoring these changes can speed up the final stage of crack growth.

Approach to Testing

Fatigue failure analysis doesn’t rely on a single test. Instead, it’s a combination of on-site inspections, lab work, and computer-based modeling. Each piece of evidence helps reveal how close your part is to reaching its breaking point.

Laboratory Methods

Technicians can remove small samples from a component (or test a standardized specimen of the same material) to see how its physical properties respond to cycling. Typical lab setups apply bending, torsion, or tensile loading that mimics the conditions your equipment faces. It’s like a snapshot of how many cycles your component can endure before cracks appear. Metallurgical evaluations might also show microscopic flaws or impurities that accelerate fatigue.

Advanced Software and Modeling

Tools like finite element analysis simulate stress across a component, helping identify high-risk zones in complex or large structures without removing samples. By inputting material properties and load data, you get a visual of where cracks might develop. Providers like Red River LLC often pair these simulations with real-world inspections to validate the results. For a deeper dive, see how to perform fatigue failure analysis step by step.

What is Fatigue Failure Analysis and Its Importance for Industries

Fatigue failure analysis shows how small cracks from repeated stress can lead to sudden equipment failure. It’s crucial in industries with pressurized systems or rotating machinery, helping prevent downtime and protect workers. By spotting weak points early and adjusting operations or inspections, you can improve safety and extend equipment life.

Take Action with Fatigue Failure Analysis

Don’t wait for small cracks to grow into major breakdowns. Partner with trusted experts like Red River LLC to ensure your pressure vessels and modular skids meet the highest safety standards. Contact us today to secure your equipment, your staff, and your investment.

Frequently Asked Questions

1. How to perform fatigue failure analysis

Fatigue failure analysis typically involves visual inspection, fractography using microscopes, material testing, and stress analysis. Engineers also review loading history, environmental conditions, and perform simulations to identify the root cause.

2. Why is fatigue failure analysis important

Fatigue failure analysis is important because it helps prevent unexpected breakdowns in structures or machinery, improves safety, and guides better material selection and design to extend service life.

3. How long does a fatigue failure analysis typically take?

It varies based on the part’s complexity and how thorough you need the testing to be. Some inspections wrap up in a few days, while comprehensive lab tests plus simulations can require weeks.

4. Can fatigue failure happen in non-metal materials?

Yes. Plastics, composites, and even ceramics can show fatigue-related damage. Each material has unique stress tolerance, so the analysis process must be tailored accordingly.

5. Is fatigue failure analysis mandatory for pressure vessels?

In many regulatory frameworks, repeated inspections and integrity assessments are mandatory. While “fatigue failure analysis” might not always be named in the code, nearly every set of rules demands some form of repeated-stress assessment.

Key Takeaway

- Fatigue is about repeated stress, not just one big overload.

- Early cracks can be microscopic, so routine checks matter.

- Computing techniques like finite element analysis can map out likely high-stress zones.

- Integrating lab tests with on-site evaluation offers the best chance to catch hidden flaws.

- Proactive fatigue failure analysis saves money, prevents emergencies, and keeps everyone safer.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

- Fatigue Failure Analysis: Red River LLC

- Why is Structural Failure Analysis Important? Red River LLC

- Understanding Structural Failure Analysis for Pressure Vessels

- Corrosion Failure Analysis Explained

- Metallurgical Failure Analysis Guide Red River LLC

- Mechanical Failure Analysis for Reliability| Red River LLC

About Author