Molecular sieves are powerful filtration tools used across industries like oil & gas and pharmaceuticals for precise moisture and impurity removal. They’re effective but come with downsides: high regeneration costs, sensitivity to contaminants, and environmental concerns. Alternatives like activated alumina or membrane systems may offer lower-cost, lower-maintenance solutions depending on your application.

Understanding Molecular Sieves

Understanding molecular sieves is crucial for industries that require precise separation processes. Molecular sieves play a pivotal role in optimizing operations and reducing inefficiencies across multiple industrial applications.

What Are Molecular Sieves?

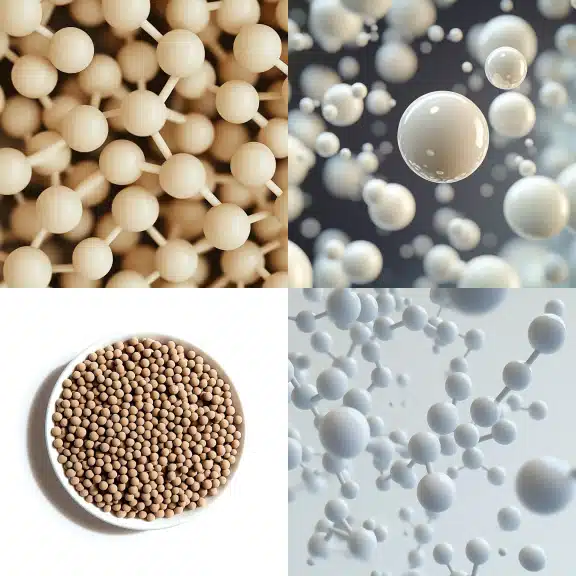

Molecular sieves are synthetic or natural materials with tiny, uniform pores that can selectively adsorb molecules based on size. This unique property makes molecular sieves indispensable for processes that require precise molecular separation. Whether you’re managing gas purification, drying, or chemical processing, molecular sieves offer exceptional utility. Molecular sieves help filter impurities, ensuring the final product’s purity and efficiency.

Common Uses of Molecular Sieves in Industry

Molecular sieves are utilized across numerous industries. In oil and gas, molecular sieves serve as drying agents for gases and liquids, preventing impurities from compromising product quality. In power generation, molecular sieves safeguard turbines and other machinery by eliminating moisture that could cause corrosion or operational failures. Meanwhile, molecular sieves catalyze reactions in chemical production and limit the formation of unwanted byproducts.

Why Are Molecular Sieves Popular?

Molecular sieves’ widespread use is attributed to their effectiveness and reliability. Molecular sieves thrive under extreme conditions, maintaining their performance without degradation. Molecular sieves are often seen as a cost-effective solution for refining processes and boosting operational efficiency. Additionally, molecular sieves’ versatility allows them to be customized for specific applications, enhancing their appeal across various sectors.

The Drawbacks of Molecular Sieves in Industrial Applications

Limited Lifespan and Durability Concerns

One significant downside of molecular sieves is their limited lifespan. Over time, molecular sieves’ filtering efficiency diminishes, necessitating frequent replacements. This degradation of molecular sieves can disrupt operations and increase maintenance costs.

High Cost of Regeneration and Replacement

Regenerating molecular sieves often requires high temperatures and precise conditions, which can be expensive. Moreover, molecular sieves replacement involves downtime, adding to operational expenses.

Sensitivity to Contaminants and Fouling

Molecular sieves are particularly vulnerable to fouling from oils, particulates, and impurities. This sensitivity reduces molecular sieves’ effectiveness and demands frequent maintenance, especially in harsh industrial environments.

Environmental and Safety Issues

Using molecular sieves may lead to environmental challenges. Improper disposal of spent molecular sieves can cause environmental contamination. Compliance with molecular sieves regulations adds another layer of complexity and cost.

Alternatives to Molecular Sieves: What Are Your Options?

Comparing Molecular Sieves to Activated Alumina

Activated alumina is a viable alternative to molecular sieves, particularly in scenarios where moisture control is crucial. Unlike molecular sieves, activated alumina is less sensitive to contaminants and requires less frequent regeneration. This makes activated alumina a more cost-effective option than molecular sieves in some applications.

When to Consider Alternative Filtration Technologies

If the limitations of molecular sieves, such as high maintenance costs and sensitivity to fouling, are becoming a burden, it may be time to explore other technologies. Options like activated carbon, silica gel, or advanced membrane systems offer potential benefits depending on specific industrial needs. Evaluating these alternatives can lead to more sustainable and efficient operations.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

How do molecular sieves examine other desiccants in moisture control?

Molecular sieves are extremely effective in moisture control due to their uniform pore size, which allows molecular sieves to selectively adsorb water molecules even at low humidity levels.

Can molecular sieves be used in meals and pharmaceutical industries?

Yes, molecular sieves are extensively used in the food and pharmaceutical industries due to their capacity to create a dry surrounding and remove moisture that would smash products or affect their balance. However, there are some considerations to keep in thoughts. For instance, the regeneration procedure for molecular sieves can contain high temperatures, which might not be suitable for all packages. Additionally, the cost of the use of molecular sieves in those industries may be higher than different alternatives, so it is crucial to weigh the benefits in opposition to the capacity downsides, such as value and sensitivity to contamination.

What are the environmental influences of using molecular sieves?

The environmental impacts of molecular sieves in most cases stem from their regeneration and disposal strategies. Regeneration regularly requires high strength intake, which can contribute to carbon emissions. Additionally, if molecular sieves are not disposed of properly after their beneficial existence, they could probably launch harmful chemical substances into the surroundings. Some newer technology intends to limit these environmental effects, however, it’s crucial to observe proper disposal protocols and take into account the lifecycle of molecular sieves while evaluating their ordinary environmental footprint.

How does the value of molecular sieves compare to other filtration technologies?

Molecular sieves tend to be greater pricey than other filtration technology, which includes activated carbon or silica gel, due to their high performance and precision. The fees associated with molecular sieves include not only the preliminary purchase but also the continued costs of regeneration and ability replacement because of their shorter lifespan. In contrast, alternatives like activated alumina or membrane filtration may also provide a higher cost-gain ratio in specific programs where absolute precision isn’t always as important. When choosing a filtration era, it’s critical to recollect each of the premature fees and the lengthy-term operational fees.

Are there any emerging technologies that could replace molecular sieves in commercial applications?

Yes, numerous emerging technologies could function as options for molecular sieves. For instance, advanced membrane filtration is gaining traction in industries that require specific separation and filtration. These membranes can be engineered to selectively filter out particular molecules, much like molecular sieves, however, they often have the benefit of longer service life and lower sensitivity to contaminants. Additionally, hybrid structures that integrate multiple filtration technologies, consisting of membranes with activated carbon, are being evolved to offer more efficient and value-effective answers. As those technologies develop, they will offer possible alternatives to molecular sieves in diverse commercial packages.

Key Takeaways

- Molecular sieves are critical for precise separation and moisture control in industrial processes.

- Their uniform pore size makes them ideal for filtering out specific molecules, especially water.

- Common industries using them include oil & gas, power generation, and pharmaceuticals.

- Major drawbacks include short lifespan, high regeneration costs, and vulnerability to fouling.

- Environmental and disposal concerns must be managed carefully to avoid contamination.

- Alternatives like activated alumina, silica gel, or membrane systems may offer better cost-efficiency or lower maintenance in certain cases.

- Emerging technologies are beginning to challenge molecular sieves with more sustainable, adaptable solutions.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author