Fuel oil pressure vessel separators are vital for separating fluids and gases safely under pressure. They boost efficiency, extend equipment life, and maintain compliance in industries ranging from oil and gas to water treatment. Prefabrication ensures quality, lowers costs, and reduces on-site risks.

Why Are Fuel Oil Pressure Vessel Separators Used In Industry

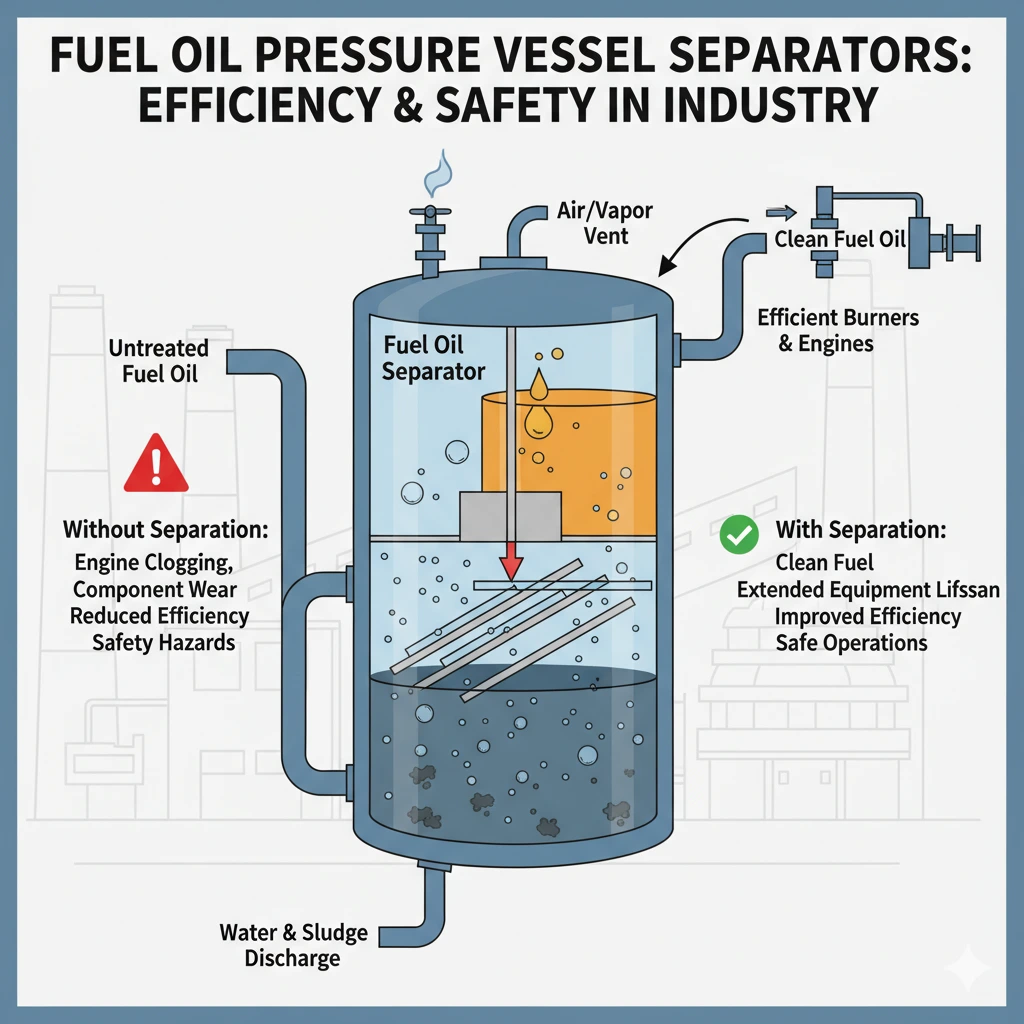

Fuel oil pressure vessel separators handle the job of keeping your fluids or gases at carefully managed pressures, all while splitting them into separate phases. But why are fuel oil pressure vessel separators used in industry? They play a critical role in removing water from oil, separating gas from liquid, or filtering impurities before they harm your equipment. Pressure vessels must withstand demanding conditions, and meeting strict industry standards for safety is essential. Studies from Red River show that each vessel is meticulously designed to handle specific temperature and pressure ranges, so your business avoids problems like leaks, bursts, or off-spec product.

Understanding the Basics

A pressure vessel separator is a heavy-duty container with internal parts like baffles that slow fluid flow, letting heavier particles or water settle while lighter gases rise. It separates multiple phases such as oil, water, and particulates, sending each to its own outlet. Unlike simple filters, these separators handle multiphase separation under pressure, making them essential in industries where water contamination is a problem, like oil refineries and marine fuel systems. For more details, see how does a fuel oil pressure vessel separator work.

Ensuring Operation Safety

Separating pressurized fluids requires proper design and fabrication, usually following ASME guidelines. Regulators often require inspections to check welds and components. This helps extend vessel life, reduce risks, and maintain consistent quality.

Industry Reliability

According to Red River (Red River Team), a well-built pressure vessel reduces downtime and can handle harsh conditions. Choosing a trusted manufacturer ensures the vessel meets safety standards, has strong welds, and performs reliably. These separators are a smart choice for facilities needing steady operation and safety.

Key Uses in Various Sectors

Fuel oil pressure vessel separators do much more than just remove water from oil. They also play a huge role in several other industries that count on them for smooth day-to-day operations. You might see them called multiphase, two-phase, or even three-phase separators. Each version is engineered to handle specific fluid types, from raw hydrocarbons to wastewater, boosting your efficiency and product quality.

Oil and Gas

The oil and gas industry uses separators to remove water, solids, and contaminants from hydrocarbons before refining or transport. These units protect equipment in harsh environments. See diesel pressure vessel filter separator for similar systems.

Separators also handle gases like propane and helium. Red River notes they protect turbines and compressors from moisture and solids, preventing costly downtime.

Water Treatment

Water treatment plants also depend on pressure vessels to remove sediment, sludge, and other unwanted materials. For instance, you might treat surface water to make it drinkable or you may purify wastewater to meet environmental regulations. Some of these vessels hold filtration media that capture contaminants, while others focus on separating water from oil-based fluids. If you have a large-scale operation, each vessel can be customized in size, shape, and pressure rating to handle your daily throughput.

In fact, an industrial water treatment facility might rely on a series of pressure vessels, each addressing a different stage in the purification process. A well-orchestrated system not only meets local regulatory standards, but may help you recycle water internally. That could reduce operating costs and environmental impact. If you want to compare how a water-based setup differs from a fuel-based one, you can check out industrial fuel water separator vessel.

Consider Prefabrication Benefits

Prefabrication is becoming more common in the pressure vessel world. Instead of building these massive units on-site, skilled teams fabricate them in a controlled environment and then transport them fully or partially assembled. This approach can help you lower overall costs and speed up project timelines. You escape the hassle of weather delays, and you can dramatically reduce on-site exposure hours for welders, inspectors, and other specialized workers.

Cost and Efficiency

When spools, piping packages, or entire skid-mounted systems are built in a workshop, you gain the advantage of consistent manufacturing conditions. That often means fewer mistakes compared to on-location assembly, plus better coordination of materials. Prefabrication can cut shipping and inspection times because everything is handled at one central site. According to Red River (Red River Team), BIM modeling and other advanced software can detect conflicts in design early, leading to fewer surprise changes during installation. Many clients see measurable cost savings, not just on materials, but on overall labor hours.

By the time the pressure vessel arrives at your facility, much of the complex work has already been done. That significantly streamlines final hookups. Your team can schedule deliveries in sync with installation dates, which means less downtime and minimal site disruption. You get to optimize resources, reduce wastage, and maintain a safe workspace.

Lower on Site Hazards

Construction sites have their fair share of risks. Prefabrication helps cut down on welding and other dangerous tasks that could lead to injuries or site accidents. The logic is simple. You do not have dozens of staff in cramped spaces, juggling flame-cutting torches and heavy metal parts out in unpredictable weather. Instead, you centralize those tasks in a specialized manufacturing area. Less on-site exposure leads to lower insurance rates, improved incident rates, and greater peace of mind.

You also gain more confidence about the workmanship. The shop environment makes it easier to run quality checks, confirm that welds are consistent, and verify pressure tolerances. The result is a well-documented vessel that meets or exceeds your safety and operational targets. When you factor in potential liabilities and compliance requirements, prefabrication starts to look like a clear win on multiple fronts.

Why Are Fuel Oil Pressure Vessel Separators Used in Industry for Long-Term Success

The answer is clear, fuel oil pressure vessel separators provide efficient separation, protect valuable assets, and ensure regulatory compliance. Prefabrication amplifies these benefits by lowering costs and risks while guaranteeing quality. For industries where uptime is critical, separators are more than equipment, they’re a strategic investment.

Ready to Improve Your Operations?

Contact RedRiver LLC today to learn more about why are fuel oil pressure vessel separators used in industry and explore ASME-certified, prefabricated solutions designed for efficiency and safety.

Frequently Asked Questions

1. What is a fuel oil pressure vessel separator?

A fuel oil pressure vessel separator is a device designed to remove water and contaminants from fuel oil under pressure. It ensures cleaner fuel reaches engines and equipment, protecting them from damage and improving efficiency.

2. How does a fuel oil pressure vessel separator work?

It works by directing fuel through a pressurized vessel where water and debris are separated from the fuel. Using filters, coalescing elements, and gravity, the separator collects water and particles, allowing only clean fuel to pass through.

3. Can a pressure vessel separator handle both liquids and gases at once?

Yes, many separators are multiphase designs that manage liquids like oil and water, as well as gases. Their internal features and flow patterns allow each phase to separate into distinct layers, ensuring you gain cleaner outputs and reduce damage to downstream equipment.

4. How often should I inspect my fuel oil pressure vessel separator?

Inspection intervals vary by regulatory requirements and manufacturer guidelines, but many recommend annual or semiannual checks. You will want to assess the vessel’s integrity, check for corrosion, verify weld quality, and confirm that all safety valves are operational.

5. Is prefabrication really cheaper than building on-site?

In many cases, yes. Prefabrication in a controlled environment cuts weather-related delays, organizes material usage more efficiently, and allows for advanced modeling tools. You often see fewer mistakes, which can save you money and time across large projects.

Key Takeaway

- Well-designed fuel oil pressure vessel separators improve efficiency by separating water, gas, and unwanted solids.

- Regulatory compliance often requires certified vessels for safety and performance.

- Prefabrication environments reduce errors, speed up timelines, and lower overall costs.

- A robust separator safeguards high-value equipment like pumps, valves, and turbines from corrosion and damage.

- Each vessel is customized to handle specific operating conditions, from pressure range to temperature limits.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author