Pressure vessel failures are catastrophic events with immediate and far-reaching consequences. From explosive releases of gas and hazardous materials to environmental and economic ramifications, these failures can result in severe injuries, downtime, and costly damages. Understanding the causes, impact, and mitigation strategies is essential to ensure safety in high-risk industries.

Introduction to Pressure Vessel Failure

Pressure vessels are an integral part of many industries, quietly performing under extreme conditions to hold gases and liquids at high pressures. They are crucial to sectors such as energy production, chemical processing, pharmaceuticals, and food processing. However, when these vessels fail, the consequences can be devastating. A failure can trigger a chain of events that leads to explosive releases, environmental contamination, human injury, and significant economic losses. Understanding the aftermath of pressure vessel failure is essential for companies to minimize risk and improve safety protocols.

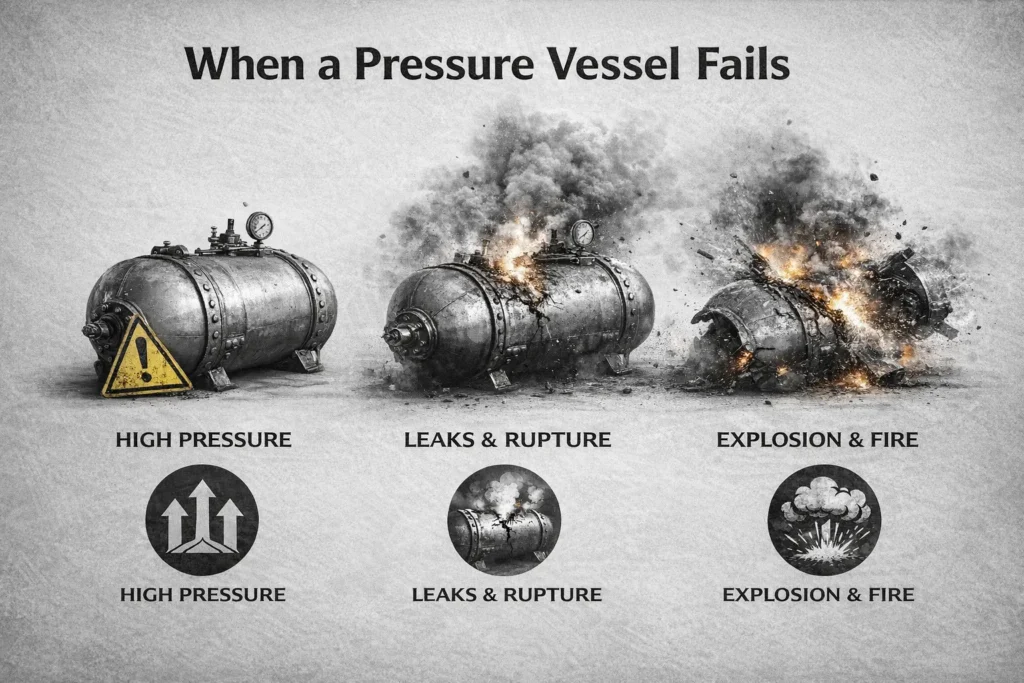

The Immediate Impact: Explosive Release

Pressure vessels are engineered to withstand immense pressure, but when they fail, the results are often explosive. The sudden release of pressurized contents can have devastating effects, including:

- Rapid Release: The pressurized contents are expelled violently, often causing an explosive release that sends shock waves through the surrounding area. This can cause immediate physical damage to infrastructure, equipment, and personnel.

- Projectile Hazards: Parts of the vessel or attached components can become high-speed projectiles, posing a significant risk to people, machinery, and surrounding infrastructure.

Fire and Combustion Hazards

If the vessel contains flammable substances, the risks increase exponentially. When a pressure vessel filled with combustible materials fails, it can lead to:

- Ignition Risk: The rapid release of gases or liquids can create a fire hazard, especially if there’s an ignition source nearby.

- Toxic Fumes: Combustion often produces hazardous fumes that can be deadly to anyone in the vicinity, particularly if the released materials are toxic or corrosive.

Environmental Consequences

The environmental impact of pressure vessel failure can be just as severe. When hazardous chemicals or pollutants are released into the environment, it can lead to:

- Spills and Leaks: The failure can lead to the release of dangerous chemicals, contaminating soil, water sources, and air quality.

- Long-term Impact: Some substances have lasting environmental effects, requiring extensive cleanup efforts and leading to potential legal and regulatory consequences.

Economic Ramifications

Beyond the immediate damage to the vessel, the financial impact of a pressure vessel failure can be staggering:

- Operational Downtime: The failure can halt operations, leading to significant losses in productivity.

- Repair and Replacement Costs: Replacing the damaged vessel and any other affected equipment can be costly, not to mention the associated repair work.

- Liability and Compensation: If the failure causes injuries, death, or environmental damage, companies may face costly lawsuits, insurance claims, and regulatory fines.

Human and Health Risks

The human cost of pressure vessel failure is severe, with both immediate and long-term consequences:

- Immediate Injuries: Shock waves, flying debris, fires, and toxic exposure can lead to serious injuries or fatalities.

- Long-term Health Effects: Exposure to chemicals released during the failure can lead to chronic health conditions such as respiratory issues or long-term organ damage.

Reputational Damage

For any company, the failure of a pressure vessel can lead to lasting reputational harm:

- Public Relations Crisis: Pressure vessel failures that result in casualties or environmental harm often attract negative media attention and public outcry.

- Loss of Trust: Customers, partners, and stakeholders may lose confidence in the company’s ability to operate safely and responsibly, leading to a loss of business and damaging relationships.

Regulatory and Compliance Implications

Pressure vessel failures don’t just result in physical and financial damage; they also have regulatory consequences:

- Investigations: Regulatory agencies may launch investigations to determine the cause of the failure and assess whether safety standards were violated.

- Penalties and Sanctions: Companies found in violation of operational and safety standards may face fines, penalties, and even operational shutdowns until compliance is achieved.

The Domino Effect: Unraveling the Aftermath

A pressure vessel failure is not just a single event; it often triggers a series of destructive consequences. The release of stored energy, shock waves, fires, toxic chemicals, and even explosions can damage surrounding structures and equipment, leading to a chain reaction of failures. Furthermore, the environmental and human toll can be long-lasting, with contaminated ecosystems and a workforce left to cope with trauma or health issues.

The Physics Behind the Explosion

When a pressure vessel fails, it releases a large amount of energy stored in the pressurized contents. This rapid release of energy causes:

- Energy Release: The stored pressure is released suddenly, like a spring snapping. This can launch debris at high speeds, resulting in structural damage and potential injuries.

- Shock Waves: The energy release often generates shock waves that can travel at supersonic speeds, causing further damage to buildings, equipment, and infrastructure.

The Thermal Aspect of Combustible Contents

If the vessel holds combustible or flammable materials, the risk of fire and explosions increases significantly:

- Flash Fires: A sudden release of flammable substances can lead to a flash fire, which may cause burns or ignite surrounding materials.

- Explosions: The release of flammable gases or chemicals can trigger large-scale explosions, compounding the destructive impact.

The Importance of Prevention

Pressure vessel failure is a high-stakes event with far-reaching consequences. While the immediate effects are devastating, the long-term environmental, economic, and reputational impacts can be just as severe. Ensuring the safety and integrity of pressure vessels through regular maintenance, adherence to safety standards, and continuous monitoring is crucial to minimizing the risks associated with pressure vessel operation.

Get Ahead of the Risks: Contact Us for Expert Pressure Vessel Solutions

Understanding the risks and consequences of pressure vessel failure is crucial to protecting your people, equipment, and environment. At Red River, we specialize in designing and manufacturing high-quality, reliable pressure vessels built to withstand the toughest conditions. Our team offers comprehensive solutions, ensuring your pressure vessels are safe, compliant, and durable.

Reach out to us today to discuss how we can help you prevent failures and ensure your operations run smoothly and safely.

Frequently Asked Questions

1. What are the number one reasons for pressure vessel failure?

Pressure vessel failure can arise due to several factors. The most common causes include fabric defects, corrosion, incorrect operation, insufficient maintenance, and design flaws. Over time, these issues can lead to the weakening of the vessel, making it prone to failure. Regular inspections and proactive maintenance are essential to address these issues.

2. How does a pressure vessel failure impact the surrounding environment?

The failure of a pressure vessel can have significant environmental consequences, depending on the contents of the vessel and the nature of the failure. If hazardous or toxic materials are involved, their release can lead to contamination of air, water, and soil. If the vessel contains flammable materials, explosions can cause widespread environmental damage.

3. What safety protocols are in place to prevent pressure vessel failure?

Safety protocols include regular inspections, adherence to design codes (like ASME), and the implementation of control systems to prevent failure. Pressure relief devices, corrosion protection, and material integrity testing are part of these safety measures to ensure pressure vessels are operated and maintained properly.

4. In the event of a pressure vessel failure, what emergency response measures are typically taken?

Emergency response involves the immediate evacuation of the area, containment of released substances, and notifying emergency services. The response team will assess the situation, manage fires or leaks, and begin cleanup to minimize harm to people and the environment.

5. How can the risk of pressure vessel failure be minimized in industrial settings?

Minimizing failure risk involves using high-quality materials, adhering to strict design and production standards, conducting regular inspections, ensuring proper operator training, and implementing a robust safety management system. Staying up to date with safety technologies and best practices is also essential.

Key Takeaways

- Pressure vessel failure can lead to explosive releases, causing damage to structures, equipment, and personnel in the immediate area.

- Flammable materials in pressure vessels increase the risk of fires and explosions, with potential for widespread destruction.

- The environmental consequences of pressure vessel failure can include soil contamination, water pollution, and hazardous air quality.

- Economic impact includes downtime, repair costs, and legal liabilities, along with long-term financial losses from operational disruptions.

- Regular maintenance and strict safety protocols are essential in preventing pressure vessel failure and ensuring compliance with industry standards.

- Effective emergency response systems can mitigate damage and protect human health in the event of a pressure vessel failure.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No subpillar set for this blog post.