AI pressure is transforming pressure vessel manufacturing by enhancing precision, safety, and efficiency through automation and real-time data analysis. At Red River, these AI-driven innovations set new industry standards while supporting smarter, safer, and more sustainable production.

Introduction to AI Pressure in Modern Manufacturing

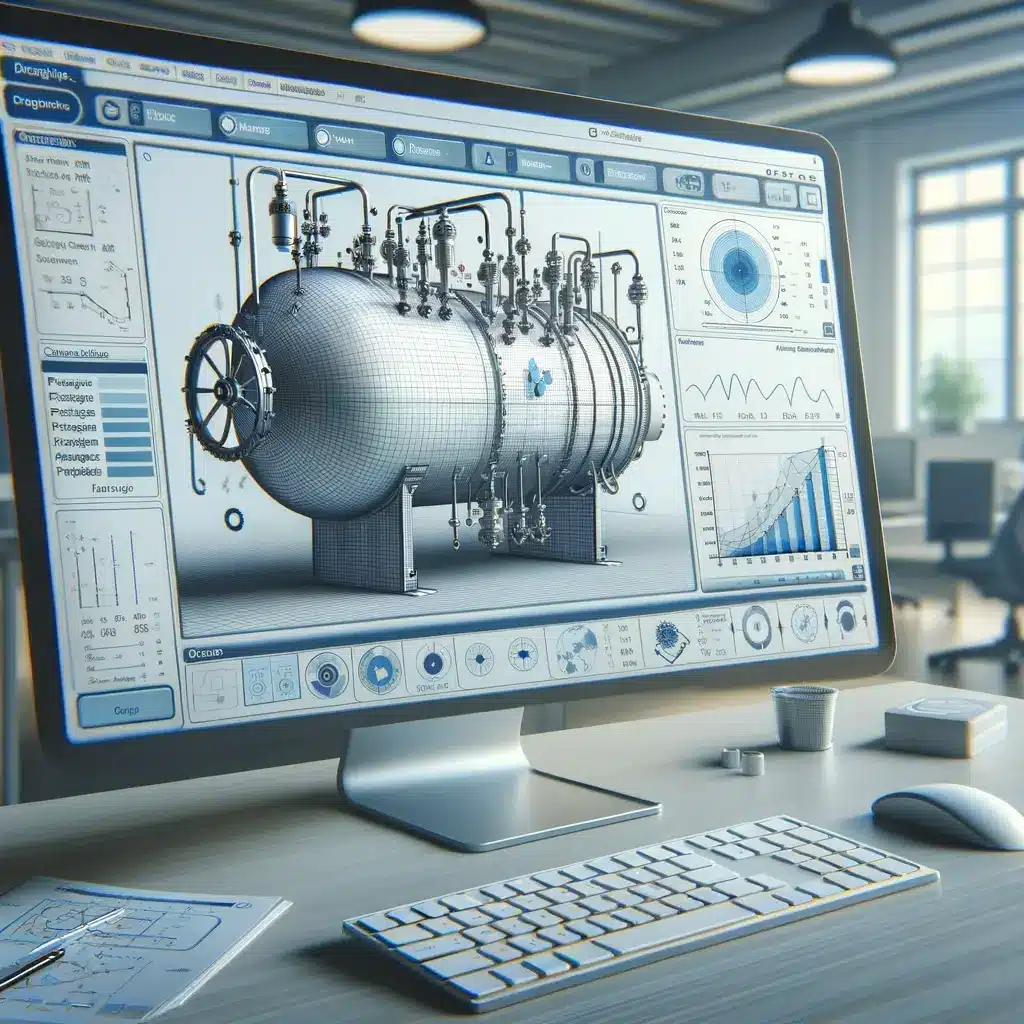

AI pressure is not just a buzzword, it has become a transformative force in industries ranging from healthcare to engineering. In manufacturing, AI pressure signifies how artificial intelligence is applied to optimize high-stakes operations under demanding conditions. At Red River, we leverage AI-driven automation and precision engineering to revolutionize how pressure vessels are designed, built, and maintained. This innovation is reshaping the standards of safety, sustainability, and efficiency.

Understanding AI Pressure Across Industries

AI pressure influences more than just industrial production. In healthcare, researchers are exploring how AI predicts and manages blood pressure with remarkable accuracy. In business leadership, executives face mounting AI pressure to adapt, integrate, and compete in a rapidly evolving technological landscape. By recognizing these broader applications, manufacturers like Red River can apply lessons learned in other fields to enhance engineering practices.

AI and Automation in Vessel Fabrication

Automation is at the heart of modern pressure vessel manufacturing. From robotic welding to predictive analytics, automation reduces human error while improving consistency. At Red River, our AI-powered systems analyze production data in real time, ensuring every vessel adheres to the highest standards. These advancements also increase safety by reducing exposure to hazardous tasks, a benefit highlighted in industrial AI research.

Case Studies AI Pressure in Real-World Engineering

- High-Efficiency Project: AI algorithms optimized vessel wall thickness, leading to a 20 percent efficiency boost.

- Custom Solution for Biogas: AI-driven simulations identified the best material for corrosive conditions, extending vessel lifespan.

- Safety-First Design: AI analyzed industry data to enhance compliance with ASME codes and elevate safety ratings.

AI Pressure Beyond Manufacturing

The concept of AI pressure extends beyond engineering. For example, predictive AI tools in healthcare monitor and forecast hypertension risks. Similarly, industries such as law and finance face external AI pressure to adopt technology under strict timelines and regulatory demands. Recognizing these parallels helps Red River innovate with a forward-looking approach.

Conclusion Harnessing AI Pressure for Industry Growth

The rise of AI pressure signals a new era where technology and human expertise converge. By embracing AI and automation, Red River is setting benchmarks in safety, efficiency, and innovation within the pressure vessel industry. Our mission is not just to build products but to deliver solutions that exceed expectations.

Partner with Red River for Smarter Solutions

Looking for a partner who understands AI pressure in manufacturing? Red River delivers precision-engineered pressure vessels designed with cutting-edge technology. Learn more about the mechanics and significance of pressure vessels or explore the different types of pressure vessels we design. We also guide industries on choosing between pressure tanks and pressure vessels and highlight the essential role of pressure vessels in modern infrastructure.

Frequently Asked Questions

1. How does AI pressure improve vessel manufacturing?

AI pressure enables predictive analytics, precision welding, and real-time quality monitoring that improve safety and efficiency.

2. What industries benefit from AI pressure?

Sectors such as oil and gas, biogas, healthcare, and finance benefit by applying AI pressure for optimization and risk reduction.

3. Can AI pressure enhance safety standards?

Yes, AI systems predict risks, improve compliance with ASME codes, and reduce workplace hazards.

4. How does AI impact material selection in vessels?

AI evaluates material properties under different conditions to choose the best option, minimizing waste and maximizing performance.

5. Why is AI pressure relevant in healthcare?

AI pressure technologies are used to forecast hypertension, optimize blood pressure treatments, and personalize medical solutions.

6. Is automation part of AI pressure?

Automation supports AI pressure by streamlining fabrication processes, enhancing consistency, and reducing downtime.

7. How does AI pressure contribute to sustainability?

AI minimizes material waste, optimizes designs for durability, and supports sustainable production practices.

8. Does AI pressure help meet client customization needs?

Yes, AI-driven systems adapt quickly to unique requirements, ensuring tailored designs and faster delivery.

Key Takeaways

- AI pressure enhances manufacturing precision, safety, and customization.

- Cross-industry learnings from healthcare and finance strengthen industrial AI applications.

- Red River uses AI to optimize design, materials, and compliance.

- Automation and AI reduce risks while improving efficiency.

- Sustainability goals are supported through AI-powered material optimization.

- Clients benefit from tailored, cost-effective, and high-performance solutions.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author