What Is 6G Welding Position? Master Advanced Pipe Welding

Why Understanding What Is 6G Welding Position Matters

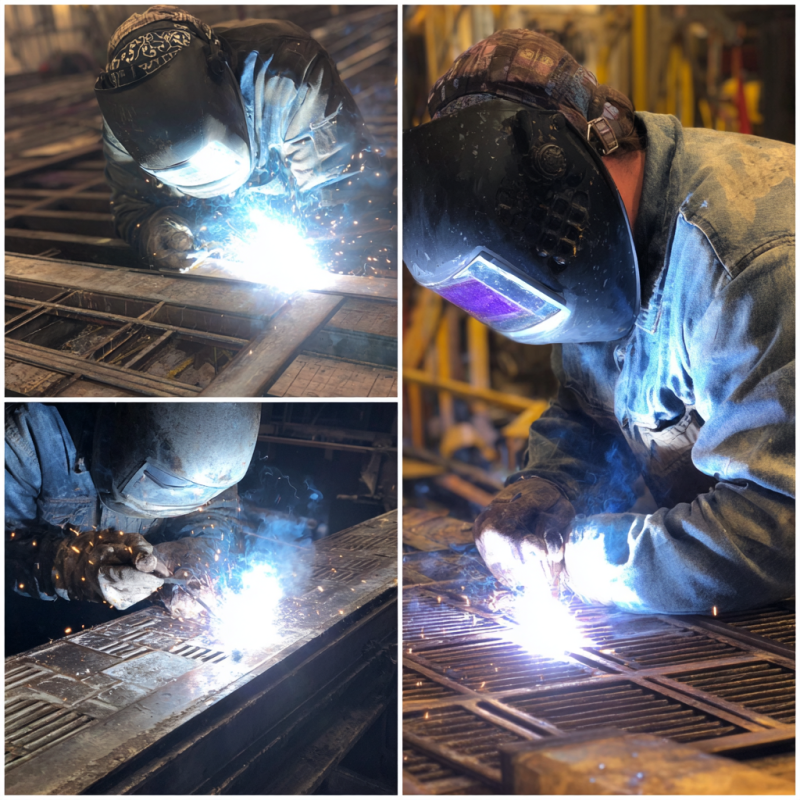

In many welding projects, the position you choose can greatly impact quality, efficiency, and safety. If you’ve wondered, what is 6G welding position? it refers to a pipe fixed at a 45-degree angle, requiring overhead, vertical, and horizontal welds in one pass. Known for its difficulty, mastering 6G develops advanced skills and precision. Many experts consider it a key certification step, as it can open doors to high-stakes pipeline or pressure vessel projects. Understanding the fundamentals makes tackling 6G welding both achievable and rewarding.

Recognize the basics of welding positions

To fully grasp 6G welding, it helps to see its place among other setups. Positions like 1G–4G for plates and 5G–6G for pipes test angles and technique. Beginners may review what are the different welding positions for guidance.

“G” positions indicate groove welds, from flat (1G) to overhead (4G) for plates, and 5G–6G for pipes. For guidance, see how many types of welding positions are there. Beginners often start with which welding position is the easiest.

Understand the 6G welding position

Among all options, 6G is extremely demanding. Many view 6G pipe welding certification as a pinnacle achievement. In this position, overhead, vertical, and horizontal skills are required. Mastering 6G pipe welding builds dexterity and confidence, preparing welders for advanced pipe welding projects.

A 6G certification qualifies welders to handle multiple positions, proving adaptability. It’s widely used in pipeline construction, power plants, and high-pressure systems requiring different weld position techniques, signaling readiness for advanced welding roles and challenging environments.

Examine the skill demands of 6G

Welding a stationary pipe at 45 degrees tests every skill. Overhead requires steady control, vertical demands precise weaving, and horizontal needs angle accuracy. Managing all sections in one pass makes 6G challenging and exacting for welders.

Welding different materials adds complexity. Stainless steel risks warping, carbon steel may crack without proper heating. The 6G position prevents pipe rotation, requiring welders to adjust electrodes and techniques on the fly for varying thicknesses, joints, and angles.

Safety is crucial in 6G welding. Overhead spatter and slag require full protective gear, including helmets. In busy shops or pressure vessel work, establish boundaries and follow strict quality checks to ensure safe, precise welds.

6G welding can be challenging for beginners, especially with overhead angles. Despite initial frustration, mastering it builds a valued skill set. Advanced facilities, including those making prefabricated modules or specialized pressure vessels, highly seek 6G-certified welders.

Explore practice strategies for success

Learning the 6G position effectively often involves regular and intentional practice. Consider these strategies:

- Start with tack welds. Your first tack welds set the alignment for the entire piece and reduce distortion. Confirm that the gap and root opening remain consistent, and ensure both pipe edges are evenly beveled.

- Use the right tools. Select electrodes or filler rods that suit your pipe material, and dial in the correct amperage or wire-feed speed. Careful prep goes a long way toward minimizing errors.

- Practice each segment. It can help to picture the pipe as three sections: overhead, vertical, and horizontal. Start by perfecting overhead, because it demands precise posture and heat control.

- Monitor heat input. In the 6G position, you can accidentally burn through or undercut if the arc lingers too long. Use a consistent travel rate, and keep a close eye on the puddle; some welders recommend a slight weave to spread heat evenly. For more detailed tips, see how to weld in 6g position.

- Adopt a comfortable stance. Because you will be twisting at odd angles, look for stable footing or knee support. A welding bench or pipe stands can help you find a more natural position for the overhead pass.

- Learn from mistakes. Every pass reveals patterns you can refine. A small slag inclusion or incomplete fusion can point to root pass issues or travel speed. If you have access to a mentor or instructor, their real-time guidance can speed your progress.

After you master the basics, consider practicing on real-world scenarios with pipes of different diameters and materials. Welding thin-wall stainless steel is a different experience from working on thick-wall carbon steel. Note your travel speeds, power settings, and angle adjustments in a simple log for future reference. Over time, this habit helps you form a personal best-practices program.

Compare 6G with other pipe welding positions

While 6G deserves its reputation, it helps to see how it stacks up against other pipe welding positions:

| Position | Orientation | Difficulty Level | Common Uses |

| 1G (Pipe Rotated) | Pipe rotates beneath the welder, usually horizontal | Easier for beginners, as gravity is consistent | School labs, basic qualifications, typical horizontal passes |

| 2G (Horizontal) | Pipe is upright, but you weld horizontally around the pipe | Moderate, focuses on bead control in horizontal | Pipeline projects, structural supports |

| 5G (Non-Rotating, Horizontal) | Pipe is horizontal and stationary, including overhead welds | Higher difficulty, especially overhead segments | Industrial piping in tight spaces |

| 6G (Non-Rotating, 45° Angle) | Pipe is fixed at a 45-degree angle, overhead, vertical, horizontal combined | One of the hardest, robust skill testing | High-pressure piping, advanced pipeline, complex prefabrication |

As the table highlights, 5G and 6G both deal with non-rotating pipes, but 6G tilts the pipe upward, introducing yet another layer of challenge. Understanding weld bead control helps skill levels progress from simpler positions up to 6G, so consider checking 1G welding position or what is 5G welding position.

Simplify your next steps

Now that you understand the 6G welding position, you might find yourself both excited and a little anxious. That is normal. Good news this path is often more attainable than it looks. If you already have a solid handle on 2G welding position or 3G welding position, you have a strong foundation to build upon.

Here is a quick blueprint for moving forward:

- Revisit your basics. If overhead welding makes you uneasy, revisit what does 3g welding position mean to sharpen your vertical welding skills.

- Seek out guidance. A mentor or certified instructor can fine-tune your technique, especially when it comes to overhead passes.

- Practice with purpose. Instead of random trials, set specific goals (mastering a root pass or perfecting a weave pattern) before each session.

- Track your progress. Log details like amperage, filler rod type, material thickness, and final bead appearance. Noticing patterns helps you figure out what needs adjusting.

- Aim for certification. Whether through a local trade program or a recognized body like the American Welding Society, an official 6G certification can boost your credibility.

Finally, each welder’s journey is different. Mastering 6G pipe welding takes weeks or months, but 6G pipe welding qualification sets you apart, builds confidence, improves weld bead control, and allows tackling advanced projects while increasing enjoyment in pipe welding work.

What Is 6G Welding Position: Key Takeaways and Next Steps

You have explored what the 6G welding position involves, why it matters, and how to develop the techniques to master it. Although often called the most difficult test in pipe welding, 6G can help you stand out professionally. Every improvement in your overhead, vertical, or horizontal welding will benefit your 6G practice. Focus on consistent training, gather feedback from pros, and recognize small wins along the way. If you want to dive deeper, check how to weld in 6g position for more targeted tips. You have the potential to succeed each hour of practice moves you closer to full confidence in 6G.

Take the Next Step in Mastering 6G Welding

Ready to master what is 6G welding position? Build your skills, seek certification, and unlock advanced opportunities in pipelines, refineries, and fabrication industries.

Frequently Asked Questions

1. How to weld in a 6g position?

To weld in the 6G position, maintain proper angle control, use steady travel speed, and practice root, fill, and cap passes carefully while keeping safety and technique consistent.

2. Why is the 6g welding position important?

The 6G welding position is important because it develops advanced skills, ensures high-quality welds in critical applications, and prepares welders for complex industrial projects.

3. Where is the 6G welding position used?

In pipelines, power plants, and industries requiring pressure vessels.

4. How do I practice 6G effectively?

Start with tack welds, break the pipe into sections, manage heat input, and log adjustments.

5. What certification covers the 6G welding position?

Certifications from bodies like AWS or ASME include 6G tests to validate advanced skill.

Key Takeaways

- The 6G welding position is a non-rotating pipe fixed at 45°.

- It requires overhead, vertical, and horizontal welds at once.

- Safety is crucial due to sparks, spatter, and awkward angles.

- Certification boosts credibility and employability.

- Practicing in segments helps build full mastery.