What is pressure vessel design and engineering is the structured process of turning process requirements into safe, code-compliant vessels from concept through testing and documentation. This guide explains codes, materials, loads, fabrication, and inspection. Red River LLC provides integrated design, fabrication, QA, and audit-ready documentation.

Understanding What is Pressure Vessel Design and Engineering

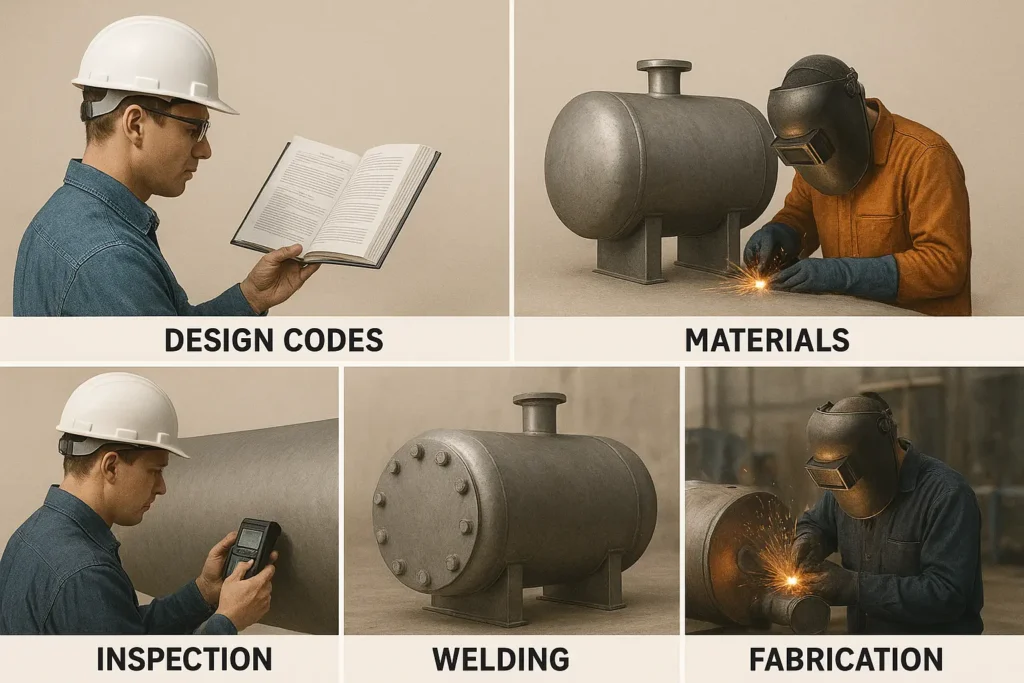

What is pressure vessel design and engineering? It is the disciplined conversion of real process data into a verified pressure boundary that operates safely and efficiently over its intended life. It aligns mechanical design, materials science, welding practices, inspection methods, and data control so that every decision is traceable. The answer to It starts with gathering credible inputs, selecting the governing code, sizing components, validating details, and compiling a complete Manufacturer’s Data Report.

It ensures that owners receive a vessel that starts up smoothly, passes audits, and can be maintained with confidence. In practice, It delivers calculations, drawings, weld procedures, NDE plans, test records, and nameplate data that are internally consistent.

Core deliverables that define success

Pressure vessel design and engineering results in a single source of truth. That includes the compliance matrix, design calculations, general arrangement and detail drawings, weld maps, material test reports (MTRs), welding procedure specifications (WPS), procedure qualification records (PQR), welder qualifications, NDE reports, heat treatment charts, hydro or pneumatic test certificates, and the Manufacturer’s Data Report (MDR). When teams ask What is pressure vessel design and engineering trying to achieve, the answer is a vessel that meets code limits with documentation that proves it.

From Data Sheet to Design: Inputs, Codes, and Materials

Pressure vessel design and engineering without accurate inputs is guesswork. Begin with design pressure, design temperature, operating ranges, corrosion allowance, fluid properties, credible transients, and cleanliness requirements. Choosing the right code path is central to Pressure vessel design and engineering because joint categories, weld efficiencies, MDMT checks, PWHT rules, and acceptance criteria flow from that choice.

Materials and corrosion strategy

Part of Pressure vessel design and engineering is material selection that balances strength, corrosion resistance, and availability. Carbon steel, low alloy, stainless, duplex, and nickel alloys each address different media and temperatures. A recurring task within Pressure vessel design and engineering is verifying MDMT and toughness for low temperature, along with creep and relaxation checks at high temperature.

Geometry, Thickness, and Nozzles

Pressure vessel design and engineering when it comes to geometry is the translation of loads into thickness for shells and heads, along with reinforcement for openings. Head selection among hemispherical, 2:1 ellipsoidal, and torispherical drives cost and mass. Nozzle reinforcement calculations confirm that the cutout is compensated. In daily practice, it means ensuring that calculations, details, and weld maps align without contradictions.

Flanges and tightness

Another piece of pressure design and engineering is tightness control. Gasket type, flange class, seating stress, and bolt load targets are specified so joints stay tight through temperature cycles. Leak testing and verified torque procedures complete the chain that pressure design and engineering must document.

Loads, Stress Categories, and Failure Modes

Pressure design and engineering if not a disciplined approach to loads. Internal and external pressure, deadweight, wind, seismic, nozzle loads, transport, lifting, and thermal gradients are combined into credible cases. Stress is classified into primary membrane, primary bending, and secondary categories, and limits are checked. When geometry is complex, pressure design and engineering uses finite element methods to validate local stresses, buckling under external pressure, and fatigue.

Preventing failure

A recurring theme in pressure design and engineering is avoiding plastic collapse, buckling, ratcheting, brittle fracture near MDMT, and creep rupture. Smooth transitions at nozzles and reduces stress concentration. For cyclic service, pressure design and engineering evaluates fatigue life and sets inspection intervals that target hotspots.

Welding, PWHT, and NDE

Pressure design and engineering around welding starts with selecting joint types and efficiencies, qualifying welding procedure specifications or WPS and procedure qualification records or PQR, and ensuring welder qualifications match essential variables. Preheat and interpass controls limit HAZ hardness for hardenable alloys. Determining when PWHT is required or beneficial is part of what pressure vessel design and engineering formalizes.

Inspection that finds what matters

NDE is not generic. Within pressure design and engineering, volumetric checks use UT or RT, surface checks use MT or PT, and alloy verification uses PMI. Acceptance criteria are aligned to service severity. Reporting links indications to weld maps and heat numbers so that repairs are traceable, which is exactly what pressure vessel design and engineering expects.

Dimensional Control, Testing, and Turnover

Pressure design and engineering in the shop includes tolerances for rolling, out-of-roundness, head fit, nozzle projection, and minimum remaining thickness after forming. Hold points catch nonconformances early. Hydrostatic testing confirms structural integrity while controlled pneumatic testing is reserved for cases where liquids are impractical. Every step is recorded because pressure design and engineering values audit-ready documentation. Thus, pressure vessel materials selection is an important part of the process.

The MDR and lifecycle integrity

The final MDR ties the entire story together. If someone asks again about pressure design and engineering long after startup, the Manufacturer’s Data Report or MDR provides the answer with calculations, drawings, material test reports or MTRs, welding procedure specifications or WPS, procedure qualification records or PQR, welder quals, NDE, heat charts, and test certificates.

Interfaces, Supports, and Operations

Pressure design and engineering with respect to interfaces is coordination with piping on nozzle loads and flexibility. For supports, skirts are sized for overturning and saddles are placed to limit bending. In operations, it feeds risk-based inspection so monitoring focuses on the true damage mechanisms rather than fixed calendars.

Digital thread and continuous improvement

Finally, pressure design and engineering in modern practice links data sheets, CAD, calc files, weld maps, material test reports or MTRs, NDE, and tests in a single digital thread. Field data then refines inspection intervals and validates design assumptions.

What is pressure vessel design and engineering in Closing

Pressure design and engineering is a lifecycle method that connects inputs, codes, materials, geometry, welding, inspection, testing, and documentation into one accountable workflow. When teams align on scope and maintain a clean data trail, it delivers vessels that are safe, efficient, maintainable, and ready for audits.

Get Expert Help Today

Partner with a team that delivers from data sheet to nameplate. Red River LLC integrates analysis, drawing detail, fabrication, QA, and a complete MDR so it becomes a predictable, high-quality outcome for your project.

Frequently Asked Questions

1. How do you design a pressure vessel

Follow a disciplined sequence. Capture design pressure, temperature, corrosion allowance, and credible transients. Select the code basis. Size shells and heads, design nozzle reinforcement, and check supports. Specify materials, welding procedures, PWHT, and NDE. Execute hydro or pneumatic tests and compile the MDR.

2. What are the key factors in pressure vessel engineering

Accurate inputs, correct code selection, realistic load combinations, validated materials and MDMT checks, qualified welding, targeted NDE, controlled testing, dimensional discipline, and a clean documentation trail.

3. Why do nozzle loads matter?

External piping loads create local stresses. Early coordination limits reinforcement, improves reliability, and prevents late redesigns.

4. When is PWHT necessary?

When required by code or beneficial for residual stress relief and toughness. The plan specifies soak temperature, hold time, and controlled heating and cooling with calibrated charts.

5. How is tightness ensured at flanges?

By selecting appropriate gasket types, confirming seating stress and bolt loads, and verifying with leak tests and documented torque procedures.

6. What belongs in a robust MDR?

Design calculations, drawings, weld maps, MTRs, WPS, PQR, welder qualifications, NDE reports, heat treatment charts, hydro or pneumatic test records, and nameplate data.

7. How do digital workflows help?

They connect design intent to fabrication and test data. This improves audit readiness and allows inspection intervals to be tuned with field performance.

Key Takeaways

- What is pressure vessel design and engineering is a lifecycle framework that delivers safe, code-compliant vessels with full traceability.

- Success depends on credible inputs, sound materials, correct code application, disciplined welding and NDE, and complete testing and documentation.

- Coordinating nozzle loads, supports, and thermal behavior early prevents rework and improves uptime.

- Red River LLC provides integrated design, fabrication, QA, and documentation to make What is pressure vessel design and engineering predictable and efficient.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

Pressure Vessel Fabrication and Manufacturing: RedRiver LLC

About Author