Firefighting Pressure Vessel: Roles, Standards, and Reliable Performance

Firefighting Pressure Vessel units store water, foam, or clean agents under controlled pressure so suppression systems can react fast when a fire risk appears. The right vessel protects people, property, and critical equipment by delivering steady flow and pressure when other supplies fail. Safety depends on good design, correct installation, and disciplined upkeep aligned with […]

Common Causes of Pressure Vessel Explosions

The mechanism of pressure vessels is the way in which a vessel is designed, constructed, and maintained to safely contain fluids under pressure. It involves material selection, structural design including shell, ends, nozzles and supports, and ongoing inspection and maintenance to ensure compliance with safety standards. Understanding the mechanism of pressure vessels helps prevent failures […]

Pressure Vessel Stress: The Essential Guide for Engineers

Pressure vessel stress and how you understand it is essential for safe, compliant design and long-term performance. The key stresses, hoop, longitudinal, and radial must be accurately calculated and managed using global codes like ASME BPVC. Modern tools like Finite Element Analysis (FEA) and failure theories identify stress concentrations to avoid catastrophic failure. Materials, corrosion, and […]

Manufacturing Process of Pressure Vessels

An overview of how are Pressure Vessels Fabricated Pressure vessels are enclosed containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. These structures are built with precision to ensure that they can safely contain the high or low pressures of the substances they hold. The importance of pressure vessels […]

Types of Industrial Pressure Vessels

Introduction to Custom Pressure Vessels in Industry A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. These vessels play a pivotal role in numerous industries. As a result, they ensure the safe containment and management of volatile substances. Importance of pressure vessels in […]

Understanding the Lifespan of Scrubbers

The Scrubber Lifespan In industries where environmental guidelines are stringent and air quality is a concern, understanding the scrubber lifespan is vital. These tools play a critical role in controlling pollutant emissions. A common question that arises regarding one’s pollution management devices is: How long do scrubbers remain? Let’s discover the factors that have an effect on the […]

The Why and How of pressure pump

Why is pressure vessel used in pumps? In the vast ecosystem of industrial machinery, pumps, and pressure vessels often go hand in hand. But why exactly are pressure vessels used in conjunction with pumps? This article dives deep into the symbiotic relationship between pumps and pressure vessels, elucidating their combined role in ensuring system efficiency, […]

What is the primary stress of a pressure vessel?

What is the primary stress of a pressure vessel? The primary stresses in a pressure vessel arise directly from the internal or external pressure acting on the vessel. These stresses are essential in determining the structural integrity and safety of the vessel. Depending on the geometry of the vessel (cylindrical, spherical, etc.), these stresses vary. […]

Understanding Failure Modes in FMEA

FMEA Failure Modes is a systematic way to identify and evaluate what might go wrong in pressure vessel design, fabrication, or operation. It helps you uncover potential issues early, assess their impacts and likelihood, and prioritize which risks to address first. When applied to pressure vessels, this approach supports safety compliance, regular inspection, and maintenance […]

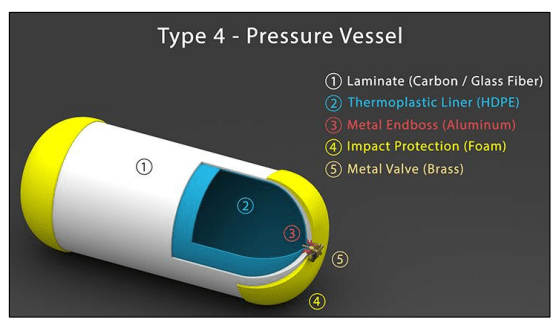

Type 4 Pressure Vessel

Type 4 pressure vessels are lightweight, high-strength tanks made from polymer liners and composite materials like carbon fiber. They’re ideal for storing compressed gases such as hydrogen and CNG, especially in weight-sensitive industries like automotive and aerospace. While more expensive upfront, they offer long-term benefits in safety, corrosion resistance, and fuel efficiency. Downsides include permeation […]