Standard vs. Custom Vessels: Choosing the Right Solution for OEM Applications

Standard OEM pressure vessels are cost-effective, fast to deliver, and ideal for predictable, low-risk applications with common operating requirements. Custom OEM pressure vessels are better suited for complex, high-risk, or highly regulated projects where precise design, specialized materials, and strict compliance are critical for long-term performance and safety. Standard vs. Custom Vessels: When to Choose […]

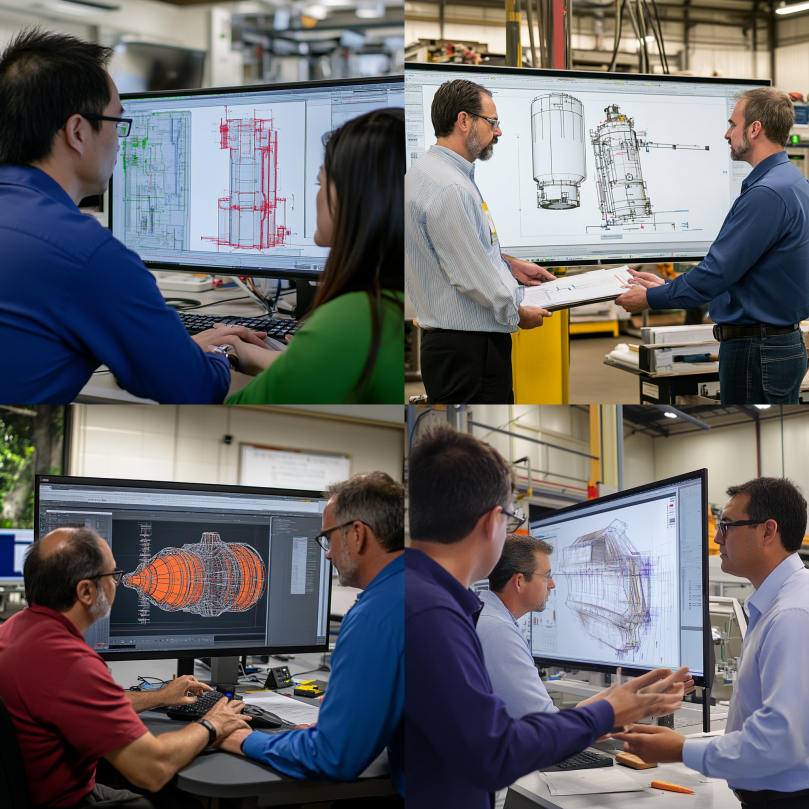

The CAD, FEA Engineering Role in OEM Pressure Vessel Design

The CAD, FEA engineering role in OEM pressure vessel is foundational to modern manufacturing. These digital tools bridge the gap between concept and fabrication by enabling engineers to design, simulate, and validate vessels before a single piece of metal is cut. Whether optimizing wall thickness, predicting stress behavior, or ensuring compliance with ASME codes, CAD […]

OEM Vessel Fabrication Innovations: Enhancing Pressure Vessel Strength and Precision

OEM vessel fabrication innovations like robotic welding, CNC machining, additive manufacturing, advanced NDT, and digital twins are transforming pressure vessel manufacturing by improving precision, reducing errors, speeding production, and lowering costs across industries with strict performance and safety requirements. As these technologies enable more customized, scalable, and sustainable fabrication, manufacturers must adopt them to stay […]

Achieving OEM Build Precision: Meeting Tight Tolerances in Pressure Vessel Builds

Achieving OEM Build Precision in Pressure Vessel Manufacturing Achieving OEM build precision is paramount in pressure vessel manufacturing, where meeting tight tolerances is not just a requirement but a critical factor influencing safety, operational performance, and regulatory compliance. In this highly specialized field, precision ensures that every pressure vessel integrates seamlessly into broader system architectures, […]

Modular vs Integrated Design in OEM Pressure Vessels

Modular vs Integrated Design: Choosing the Best Pressure Vessel Strategy Modular vs. Integrated Design is a key consideration in OEM pressure vessel engineering, sparking ongoing debate among manufacturers, system designers, and engineers aiming to optimize performance. The choice between Modular vs Integrated Design plays a crucial role in determining how well a pressure vessel system […]

Optimize Flow Using Vessels in U.S. Factories

Improving Process Flow in Factories Using Vertical Pressure Vessels Improving process flow in factories using vertical pressure vessels has rapidly become a strategic priority for modern American manufacturing facilities. As businesses seek innovative solutions to maximize production efficiency and space utilization, more operations are turning to vertical pressure vessels to optimize flow using vessels designed […]

Glycol Called Antifreeze

Glycol acts as an antifreeze by lowering the freezing point and raising the boiling point of fluids, protecting engines and industrial systems from extreme temperatures. Ethylene glycol is highly efficient but toxic, while propylene glycol offers a safer, environmentally friendly alternative for sensitive applications. Introduction to Glycol as Antifreeze Overview of Antifreeze Solutions Antifreeze solutions […]

Metallurgy Impact on Welding and Fabrication

Understanding metallurgy is essential for achieving high-quality, reliable welds and durable fabrication results. The Metallurgy Impact on Welding and Fabrication influences heat behavior, strength, corrosion resistance, and overall weld performance. By recognizing how metal properties affect fabrication, welders can avoid defects and ensure long-term safety. RedRiver LLC uses advanced metallurgical knowledge to deliver dependable pressure […]

Why Training is Essential in Welding and Fabrication

Training is the backbone of quality in welding and fabrication. At Red River, we invest heavily in continuous education from safety and advanced techniques to quality control ensuring our team delivers precise, efficient, and regulation-compliant results. Skilled training reduces errors, boosts efficiency, and increases client satisfaction, making us a trusted partner for pressure vessels and […]

Understanding Cryogenic Hydrogen Storage Pressure

Cryogenic hydrogen storage plays a crucial role in advancing sustainable energy solutions. Cryogenic pressure vessels, carefully engineered with advanced insulation and safety features, are essential for storing hydrogen at ultra-low temperatures. Our commitment to innovation ensures that each cryogenic hydrogen storage solution is efficient, safe, and compliant with industry standards. Introduction to Cryogenic Hydrogen Storage […]