Conductivity Levels in Drinking Water: Why They Matter for Safety and Industry

Conductivity levels in drinking water help reveal how much dissolved material is present in a water supply. When conductivity shifts outside safe ranges, it can signal elevated salts, metals, or other contaminants that affect taste, process performance, and long-term safety. Regular monitoring supports cleaner water and more reliable industrial systems. RedRiver LLC helps operators manage […]

Compliance with Regulation 4 for ASME Pressure Vessels: What It Means for Safe, Reliable Operations

Compliance with Regulation 4 for ASME Pressure Vessels is a practical safety commitment, not just paperwork. It ensures vessels are designed, built, tested, and maintained to manage pressure risks while meeting recognized standards. When you treat Regulation 4 as a lifecycle practice, you reduce downtime, prevent failures, and protect teams. RedRiver LLC supports compliant fabrication […]

Effective Scrubber Machine: Ensuring Safety and Efficiency in Industrial Operations

The Effective Scrubber Machine is a critical component in industrial facilities, designed to remove harmful gases and contaminants from process streams while ensuring compliance with pressure vessel safety standards. This blog explores the types of scrubbers, their applications, and how Red River LLC delivers reliable and customized solutions. Learn about maintenance, inspection practices, and industry […]

Why Is Fatigue Failure Analysis Important? Red River LLC

Fatigue failure analysis is crucial for identifying early signs of material damage caused by repeated stress, especially in high-risk components like pressure vessels. It helps prevent catastrophic failures, enhances safety, reduces downtime, and extends equipment lifespan through proactive maintenance and inspections. Understanding Why Is Fatigue Failure Analysis Important Fatigue failure occurs when a material is […]

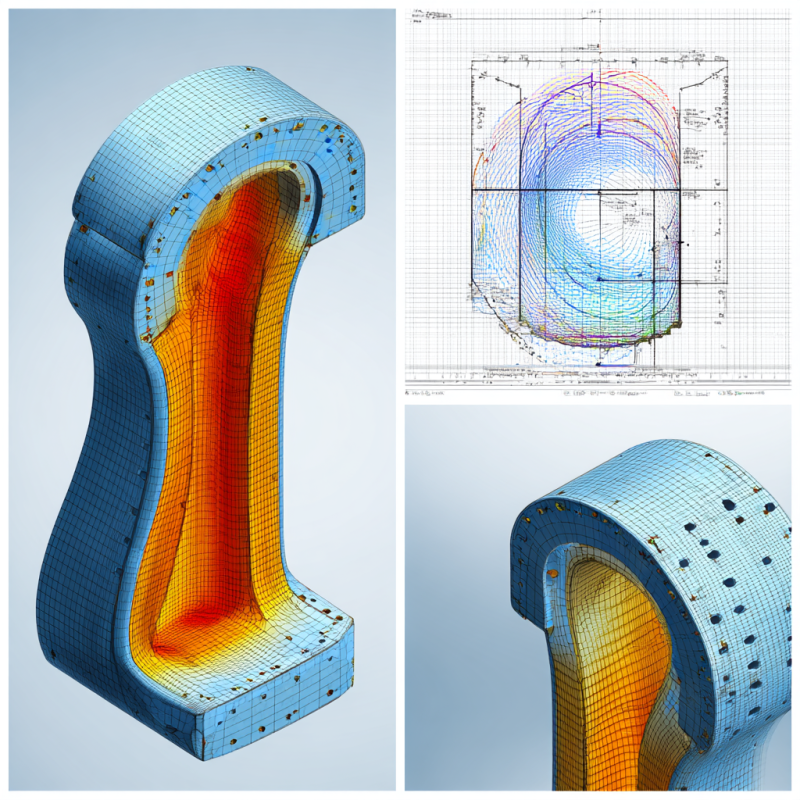

How to Perform Fatigue Failure Analysis? Red River LLC

Performing fatigue failure analysis involves gathering operational and material data, using methods like visual inspection, nondestructive testing, fractography, and computational tools such as S-N curves and finite element analysis. Identifying fatigue triggers like cyclic loading, environmental factors, and design flaws helps prevent crack growth. Combining thorough inspection schedules, quality materials, and advanced modeling ensures safer, […]

How to Perform Structural Failure Analysis: Red River LLC

Structural failure analysis is a hands‑on engineering process for diagnosing why components fail through inspections, testing, design review, and simulation to prevent future breakdowns. It helps make structures stronger, safer, and more reliable by catching weak spots early. Why How to Perform Structural Failure Analysis Is Important If you want to know how to perform […]

Understanding What Is Structural Failure Analysis for You

Structural failure analysis identifies the root causes of cracks, collapses, or weaknesses in buildings, machines, and pressure vessels, helping prevent costly downtime and accidents. By combining inspection, material testing, and prefabrication methods, companies like Red River LLC ensure safer, more reliable operations backed by ASME certifications. Why is Structural Failure Analysis Matters If you’ve ever […]

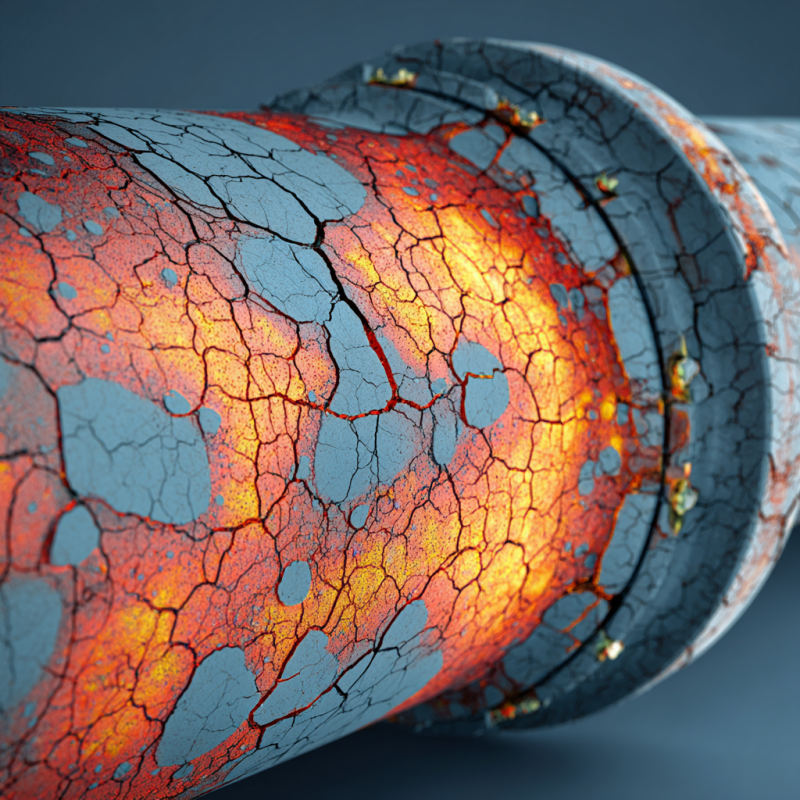

Why is Corrosion Failure Analysis Important Red River LLC

Corrosion failure analysis is essential for detecting and preventing hidden metal deterioration, ensuring industrial safety, regulatory compliance, and extended equipment lifespan. Using techniques like corrosion detection, mechanical failure analysis, and structural failure analysis, industries from oil and gas to marine services can proactively prevent costly accidents, downtime, and environmental hazards. Understanding Why is Corrosion Failure […]

How to Perform Corrosion Failure Analysis Red River LLC

Corrosion failure analysis helps identify the root causes of metal deterioration by combining visual inspections, lab tests, and design evaluations to prevent future damage. Implementing these steps, along with controlled prefabrication and quality measures, extends equipment lifespan and reduces downtime. Why How to Perform Corrosion Failure Analysis Matters Corrosion is a leading culprit behind unexpected […]

The Essential Guide to What Is Corrosion Failure Analysis

What is corrosion failure analysis helps identify why corrosion occurs in metal structures and pressure vessels, using corrosion detection and a material failure analysis process to prevent costly failures. Early analysis and preventive strategies extend equipment lifespan, improve safety, and reduce maintenance costs. Why What Is Corrosion Failure Analysis Matters Corrosion can quietly weaken your […]