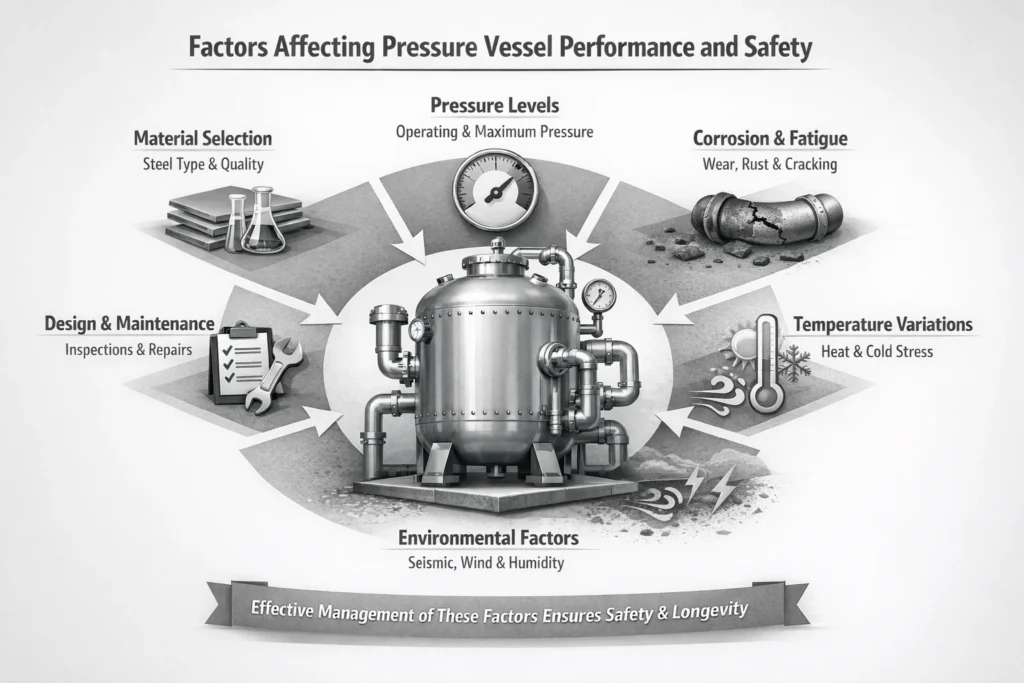

Pressure vessels are vital in many industries, and their performance is impacted by factors like material selection, pressure levels, corrosion, and fatigue. Proper installation, regular maintenance, and safety measures are essential to avoid failures and ensure longevity. Additionally, environmental conditions and operational factors like wind, earthquakes, and temperature changes must be considered during design and use.

Understanding the Key Factors That Impact Pressure Vessel Performance and Safety

Pressure vessels are essential in various industries, from oil and gas to chemical processing, where they serve to contain and handle substances under high pressure. The performance, safety, and longevity of these vessels are influenced by several factors that can impact their design, operation, and maintenance requirements. Let’s explore the key factors that affect pressure vessels and the importance of managing these considerations effectively.

Design Factors

- Material Selection: The choice of material is crucial in pressure vessel design. Whether it’s high-strength carbon steel, corrosion-resistant stainless steel, or advanced composite materials, the selected material must withstand high pressures, resist corrosion, and handle the heat generated during operation. Engineers often choose materials based on the specific conditions the vessel will face, including the type of contents and exposure to environmental factors.

- Shape and Structure: The shape of a pressure vessel, whether cylindrical, spherical, or other configurations, influences how pressure and stress are distributed across its structure. Cylindrical shapes are commonly used for their ability to withstand internal pressure effectively, while spherical vessels are excellent for applications requiring even stress distribution. The design must ensure the vessel retains structural integrity under operational conditions.

Operational Factors

- Pressure Levels: Pressure vessels are designed to operate within specific pressure ranges. Exceeding these limits can compromise the vessel’s integrity, potentially leading to leaks or catastrophic failure. Regular monitoring and adherence to operational guidelines are essential to maintain safety and prolong the vessel’s lifespan.

- Temperature Variations: Extreme temperature changes, whether from high heat or freezing conditions, can affect the vessel’s material and lead to thermal stress. This is particularly relevant in applications where vessels are exposed to rapid temperature shifts. Thermal expansion and contraction can weaken materials over time, making them more susceptible to cracking and other damage.

- Contents of the Vessel: The type of substance contained within the vessel, whether gases, liquids, or chemicals, affects its durability. Corrosive or reactive substances can cause internal corrosion, compromising the vessel’s structural integrity. Proper material selection and protective coatings are often employed to mitigate the effects of corrosive contents.

Corrosion Factors

- Internal Corrosion: The interaction between the vessel’s contents and its interior walls can lead to internal corrosion, especially if the substance is reactive. For instance, water with dissolved oxygen or chemicals like acids can cause internal corrosion over time, weakening the vessel’s structure and making it susceptible to leaks.

- External Corrosion: Pressure vessels exposed to harsh environmental conditions, such as saltwater, humidity, or chemical fumes, can experience external corrosion. This is especially common in outdoor applications or environments with exposure to weathering and contaminants. Protective coatings, such as paint or galvanizing, are often applied to prevent or reduce external corrosion.

Fatigue and Stress Factors

- Cyclic Loading: Repeated cycles of pressure and temperature changes can lead to fatigue in the vessel’s material. This fatigue manifests as small cracks that gradually grow over time, especially in areas that experience the highest stress. Fatigue can eventually cause structural failure if not monitored and managed.

- Stress Concentration: Certain areas of a pressure vessel, such as joints, welds, and areas around nozzles, may experience higher stress levels. These stress concentrations make the vessel more prone to cracks and other forms of wear. Proper design and reinforcement in high-stress areas are essential to prevent premature failure.

Maintenance and Inspection

- Regular Inspections: Routine inspections are essential for identifying early signs of wear, corrosion, or damage. By conducting regular maintenance and addressing minor issues promptly, operators can prevent small problems from escalating into serious safety hazards. Inspections are typically conducted using non-destructive testing methods to detect flaws without compromising the vessel’s structure.

- Preventative Maintenance: Implementing a proactive maintenance schedule can significantly extend the vessel’s lifespan. This includes tasks like reapplying protective coatings, testing safety valves, and checking for signs of corrosion. Preventative maintenance helps maintain the vessel’s performance and reduces the likelihood of unexpected failures.

Blown Away and Shaken Up:

- Wind’s Push: Large, exposed vessels are often subjected to strong winds in open spaces. Constant wind pressure can create stress points and amplify the force on the vessel, especially if it lacks adequate support or anchoring. Engineers must account for wind load during the design phase, especially in areas prone to high winds.

- Earthquake Shake-Up: In regions susceptible to earthquakes, ground stability is a significant concern for pressure vessels. Earthquakes can shift or destabilize vessels, leading to leaks, cracks, or even catastrophic failure. It’s essential to consider seismic activity in the vessel’s design, including additional reinforcements or flexible mounts that can absorb and reduce shock.

Standing Strong:

- Foundation and Support: A solid foundation is crucial for any pressure vessel. If the vessel’s foundation is weak or misaligned, it can result in uneven stress distribution, bending, or structural instability. Regular inspections of the foundation and support structure can help prevent these issues, ensuring the vessel remains stable under operational pressures.

Safety First:

- Reliable Safety Gadgets: Safety devices, such as pressure relief valves and gauges, are integral to managing internal pressure within safe limits. If these devices malfunction or aren’t properly maintained, they could lead to an uncontrolled buildup of pressure, putting both the vessel and surrounding personnel at risk. Routine testing and maintenance of safety equipment are essential.

Fixer-Upper Fails:

- Maintenance and Repairs: When repairs or modifications are necessary, they must be done correctly and following industry standards. Poorly executed repairs, such as improper welding or using incompatible replacement parts, can introduce weak points in the vessel, leading to potential failures. Ensuring repairs are done by qualified personnel can prevent long-term issues.

Environmental Impact

- Weather Exposure: Outdoor pressure vessels are exposed to various environmental conditions, from intense sunlight to freezing temperatures. UV exposure, drastic temperature shifts, and moisture can degrade materials over time, especially those sensitive to environmental changes like certain plastics and composites. Protective coatings and proper material selection can mitigate environmental wear and tear.

Use with Care:

- Slamming on the pressure or emptying them too fast, not following start-up or shut-down plays, or stuffing them too full can stress ’em out.

Aging Gracefully?

- Over time, materials can get less tough and more prone to getting hurt by outside forces.

Material World:

- Top-Shelf Supplies: Picking the right suppliers means the materials are solid, without any surprises that could lead to trouble.

- Making Moves: How they’re put together, like bending, smashing, or pressing, can put stress on them. The right moves keep stress low.

- Welding Wisdom: It’s all about how well they’re welded together. The right technique and some TLC afterward can make all the difference.

Keeping It Quality:

- Looking It Over: Checking things out both during and after putting them together with tests like ultrasound or X-rays helps catch any slip-ups.

- Adhering to established standards, such as those set by organizations like ASME, is essential to ensuring proper design and construction.

Skill Up:

- It’s all about the skills of the folks making them. Keeping those skills sharp means everything’s put together just right.

Beyond the Build: Negative Factors Affecting Performance

- Improper Installation: Incorrect setup can lead to misalignment, disrupting functionality, and compromising overall system performance.

- Lack of Protective Coating: Failing to apply necessary coatings or insulation increases susceptibility to rust and heat loss, reducing durability and efficiency.

- Poor Documentation: Inadequate record-keeping of construction, repairs, and tests can lead to operational issues and hinder long-term maintenance.

- Absence of Feedback: Without feedback from real-world use, future designs may miss crucial improvements, resulting in recurring issues and suboptimal performance.

Ensuring Safe and Efficient Pressure Vessel Performance

Ready to Ensure Your Pressure Vessels Perform at Their Best?

At Red River, we specialize in the design, manufacturing, and maintenance of high-quality pressure vessels tailored to your specific needs. Our team is committed to providing durable, reliable, and safe solutions to keep your operations running smoothly. Contact us today to learn more about how we can support your pressure vessel needs with precision and expertise. Let’s work together to ensure your system stays safe and efficient for the long haul!

Frequently Asked Questions

1. What are the three factors that affect pressure?

Pressure depends on force, area, and the direction of the force. A larger force or smaller area increases pressure, while the direction can impact its distribution.

2. What causes pressure vessel failure?

Pressure vessel failure occurs due to excessive internal pressure, material defects, corrosion, fatigue, or poor design. Improper maintenance and overloading can also lead to rupture or leaks.

3. What are the factors that pressure depends on?

Pressure depends on the magnitude of applied force, the surface area over which the force is distributed, and the type of fluid or gas involved.

4. What are the factors that affect the pressure of water?

Water pressure is influenced by the depth, density of the liquid, gravitational force, and the type of container or environment holding the water.

5. What are three forces that cause pressure injuries?

Pressure injuries are caused by shear, friction, and prolonged pressure on tissues. These forces reduce blood flow, causing tissue damage, especially over bony areas.

Key Takeaways

Pressure vessels are crucial in various industries and require careful consideration of material selection, pressure levels, corrosion, and fatigue to ensure optimal performance.

Proper design, including correct shape and structure, helps maintain the vessel’s integrity under operational conditions.

Regular maintenance and adherence to safety standards are essential to prevent failures and ensure long-term reliability.

Environmental factors such as temperature changes, wind, and earthquakes must be considered during the design phase to protect vessels in different conditions.

Adequate documentation and inspections are vital for identifying early signs of wear, corrosion, or damage, preventing serious issues from arising.

Continuous monitoring and feedback from real-world use can lead to improvements, enhancing the design and performance of future pressure vessels.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide