Fatigue failure analysis helps detect and prevent damage caused by repeated stress in pressure vessels and industrial equipment. By identifying early-stage cracks and stress points, it improves safety, reduces downtime, and extends equipment life. Working with certified experts ensures reliable design, quality fabrication, and smarter maintenance decisions.

Why Fatigue Failure Analysis is Important for Your Operation

Fatigue failure analysis is your key to understanding how repeated stress can quietly weaken a material until it finally cracks. This type of fatigue failure analysis focuses on the subtle signs that tell you when a component might be approaching its breaking point. While dramatic accidents sometimes steal the headlines, many failures begin under the radar. Repeated cycles of loading and unloading create tiny fissures that slowly spread through metal or other materials. By the time a visible crack forms, the underlying damage is extensive.

Good news, studying these early indicators helps you catch problems before they escalate. If you operate pressure vessels, you have a special reason to pay attention to fatigue, since minor flaws under high pressure can be catastrophic. That’s why many industries, from oil and gas to water treatment, now place a priority on material failure analysis, including specialized approaches like pressure vessel failure analysis. Each of these methods helps you understand how fatigue failure analysis works in real-world conditions, and how stress, temperature, corrosion, and operational cycles interact to affect your equipment’s long-term reliability.

Below, you will learn how fatigue cracks develop, what factors make them worse, and how you can identify weak spots through reliable testing. You will also see how experts like Red River LLC, an ASME-certified provider of modular skids and custom pressure vessels use advanced manufacturing and inspection practices to reduce the risk of fatigue. By grasping the role of fatigue failure analysis, you can plan maintenance schedules, adopt safer designs, and work with trusted partners to avoid unexpected downtime. With a better understanding of fatigue failure analysis, your team is more equipped to take preventive action.

Understanding Fatigue Failure Analysis

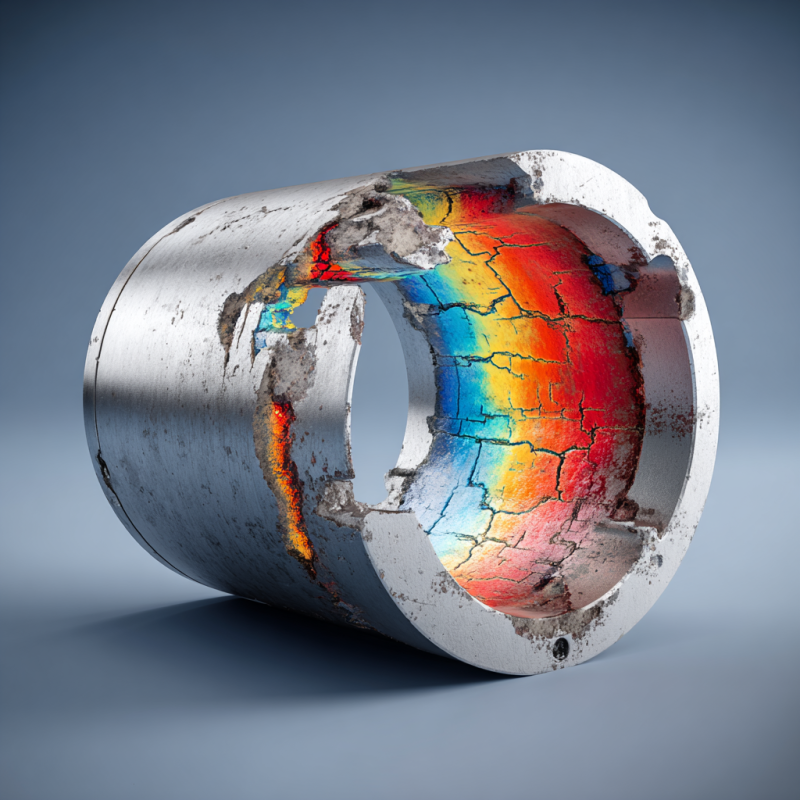

Fatigue is all about how repeated stress degrades a material over time. Whenever your pressure vessel or structure experiences cyclical loads such as internal pressure fluctuations or external vibration microscopic changes take place. Even if you do not see any cracks on the surface right now, these tiny imperfections can grow with each stress cycle. Fatigue failure analysis helps uncover these hidden issues. Eventually, they may unite into a larger crack that leads to catastrophic failure, which is why fatigue failure analysis is crucial for early detection.

You might think fatigue is mainly a concern for high-stakes applications like offshore oil rigs or high-speed aerospace parts. However, even moderate, repeated stresses can trigger fatigue if they are consistent and repetitive. A vessel used in water treatment, for instance, can experience constant changes in internal pressure from pumps, flow rate variations, and chemical treatments. These fluctuations are ideal candidates for fatigue failure analysis, which can reveal weaknesses long before they pose a risk. Over months or years, these stress cycles add up, and fatigue failure analysis gives you a method to monitor and mitigate their impact.

In fatigue failure analysis, experts typically examine how the stress amplitude (the difference between maximum and minimum stress), the number of cycles, and the material’s inherent properties affect crack initiation. For example, steels may handle a certain load for thousands of cycles, but once you exceed that threshold, cracks can begin. Fatigue failure analysis also considers how non-metallic materials behave differently, sometimes with fewer early warning signs. By studying the specific conditions in your operation, pressure range, temperature shifts, and environmental factors, you will get a better sense of how close your equipment might be to the danger zone and where to focus your fatigue failure analysis efforts.

Encouraging note: Take heart, this is a solvable challenge. With a systematic approach, you can predict a great deal about when and where fatigue damage will happen. Fatigue failure analysis is not just a technical tool, but a strategic asset for improving reliability. By integrating fatigue failure analysis into your routine maintenance and design practices, you gain an edge in preventing costly downtime and ensuring safer operations.

Why it Matters to Your Operation

- Safety: Sudden equipment failure puts people at risk.

- Cost savings: Preventive checks help you avoid costly breakdowns.

- Extended lifespan: Proper design and regular inspections help your vessel endure more stress cycles.

- Regulatory compliance: In many jurisdictions, regular assessments of fatigue life are mandatory, especially for pressure vessels.

Considering how critical these points are, it becomes clear that fatigue failure analysis is not just a nice-to-have. It is often the main line of defense against preventable accidents.

What Triggers Fatigue Failure in Pressure Vessels

Pressure vessels face unique conditions. They hold gases or liquids at pressures often far above atmospheric levels. Because the internal pressure can shift during normal cycles of filling, heating, or chemical processing, the structure endures repetitive stress. Fatigue failure analysis helps identify how these stress cycles gradually weaken the material over time. When you add potential temperature fluctuations, vibrations from pumps or adjacent machinery, and external factors like corrosion, you get a fertile setting for fatigue cracks to form, making fatigue failure analysis essential for early detection and prevention.

Common Fatigue Accelerators

- Repetitive stress cycles: Each time your vessel loads and unloads or even shifts slightly, you accumulate microscopic damage.

- Corrosion: Corrosive liquids or vapors can weaken certain spots, making them the first to crack under cyclical stress. You can explore more about how corrosion plays a role in corrosion failure analysis.

- Welding flaws: Bad welds or incomplete fusion can act as stress concentrators. Over thousands of cycles, cracks start at these weak points. Red River LLC, an ASME-certified fabricator, addresses such vulnerabilities through rigorous welding standards (including membership in the American Welding Society).

- High temperatures: Heat can change a material’s microstructure, making it more susceptible to metal fatigue.

- Frequent start-stop operations: Pressure vessels that are routinely stopped and started often undergo more stress cycles than continuously run systems.

Encouraging note: The silver lining is that you have tools at your disposal. High-quality prefabrication, such as the kind Red River LLC does in controlled shop environments, can minimize weld defects and ensure consistent quality. Fatigue failure analysis supports this by identifying areas most vulnerable to cyclic stress before they become critical. Many operators also schedule periodic inspections that measure wall thickness, track crack growth, and verify the vessel’s overall integrity. By incorporating fatigue failure analysis into these inspections, you can catch weak spots early and repair or replace components before a minor issue dictates a major shutdown.

Key Steps for Reliable Fatigue Failure Analysis

Fatigue failure analysis is more than just looking for cracks. It is a methodical process that combines observation, data collection, and theoretical modeling. When done well, fatigue failure analysis can guide your maintenance plans, inform design improvements, and improve overall safety margins. Here’s a closer look at the key steps:

Collect Operational Data

First, you need to know how your vessel or component has been used. Has it experienced pressure spikes? Temperature extremes? Document all relevant operational parameters, including cycle counts and stress ranges. If you already have an asset management system in place, check if it logs daily run times or unusual events.

Example: Water treatment vessels could log cyclical pressurization starting every morning shift and winding down each night. Over time, some facilities track thousands of cycles per year.

Visual Inspection and Non-destructive Testing (NDT)

Good news, you can detect many signs of fatigue without cutting open your equipment. By using NDT methods such as ultrasonic testing, magnetic particle inspection, or dye penetrant, you can spot small cracks or even subsurface flaws. Fatigue failure analysis often begins with these techniques to catch early-stage damage. If you suspect broader weaknesses, you might also rely on radiographic testing to get a deeper look. Larger cracks typically reveal themselves in advanced NDT scans before they become visible to the naked eye, giving fatigue failure analysis a solid foundation for further investigation.

Metallurgical Evaluation

Sometimes you need to go deeper into the material’s structure. A sample from a critical weld or a heat-affected zone might undergo microscopic analysis. This step can confirm if the crack stems from fatigue and not some other mode of failure like corrosion pitting or mechanical overload. For broader context on different modes, you can check mechanical failure analysis or metallurgical failure analysis to understand how each type handles flaws caused by stress, temperature, or chemical reactions.

Stress Analysis and Life Prediction

Once you have the data on stress ranges, you can use design codes or specialized software to estimate the vessel’s remaining fatigue life. For instance, software might simulate thousands or even millions of loading cycles in a short time, showing which areas are prone to crack formation. These simulations are at the heart of modern fatigue failure analysis. You compare these results to accepted safety standards or to ASME guidelines for allowable stress cycles, helping refine your fatigue failure analysis with precise benchmarks.

Reporting and Recommendations

Finally, a thorough fatigue failure analysis ends with clear documentation. You want a concise summary of any cracks found, material irregularities, or stresses above recommended thresholds. Clear reporting is essential to make the fatigue failure analysis actionable. Reports should also include recommended actions like re-welding or altering operational procedures and a monitoring plan to ensure that if a crack does exist, it is monitored closely for further growth as part of an ongoing fatigue failure analysis strategy.

Practical Tips to Prevent Fatigue in Your Vessels

If you are responsible for pressure vessels, you can significantly reduce the likelihood of fatigue-related damage by focusing on both design and ongoing maintenance. Here are a few straightforward yet effective measures:

Choose Materials Wisely

Select metals or composites known for strong fatigue resistance. Each material has a fatigue limit, a threshold below which it can endure infinite cycles without failure. Fatigue failure analysis helps determine whether selected materials meet the demands of cyclic loading in your specific application. If your application calls for repeated loading, pick a material that keeps the stress below that limit. Red River LLC’s solutions often match materials to specific operational requirements, ensuring you do not overpay for unnecessary strength but don’t cut corners either something fatigue failure analysis often confirms in early design reviews.

Optimize your Design

Sharp corners or sudden transitions in thickness concentrate stress, making them hot spots for fatigue cracks. Good designers know how to distribute stress more evenly. Consider adding fillets, transitions, or reinforcements where the geometry changes. Advanced computer modeling (including finite element analysis) can identify high-stress regions and help you refine the design to minimize fatigue issues.

Maintain Stable Operating Conditions

Frequent or large pressure swings accelerate fatigue damage. Try to minimize rapid start-stop cycles or severe temperature fluctuations. You might schedule starts or stops in a way that gradually ramps up or cools down the system, instead of flipping from off to on in seconds.

Embrace Prefabrication

Prefabricated modules and assemblies, made in a controlled environment, often yield better weld quality. According to Red River LLC’s research and fatigue failure analysis of field vs. shop welds, prefabrication reduces on-site exposure hours, lowers welding defects, and results in consistent material handling. Because everything is assembled in a specialized shop, you’re less likely to face environmental variables that might compromise welds. Fatigue failure analysis consistently shows that controlled welding environments reduce the likelihood of early crack initiation.

Implement Regular Inspections

A routine check can be as simple as a visual walkthrough looking for discoloration, leaks, or vibrations. Periodically, you can back that up with more advanced NDT. Fatigue failure analysis confirms that early-stage cracks are often invisible without proper testing, so combining routine checks with targeted NDT is essential. The aim is to track wear and tear before it escalates. If data from these inspections shows rising crack growth or unusual wear patterns, you can intervene quickly, another key recommendation that stems from real-world fatigue failure analysis cases.

Encouraging note: Prevention might feel like an extra step now, but every hour of prevention can save you days in repairs and lost productivity down the line.

Why Partner with a Specialist in Pressure Vessels

At this point, you may wonder if you need an outside consultant or a specialized manufacturer to handle fatigue failure analysis. While in-house teams can tackle some aspects, partnering with experts offers distinct advantages, especially when you operate under demanding conditions.

Specialized Knowledge of ASME Standards

Pressure vessels built to ASME code come with specific criteria for thickness, welding, materials, and inspection intervals. A partner holding ASME “U4 & R” stamps (like Red River LLC) has demonstrated their ability to build and repair vessels that meet these standards. This means your equipment is already starting with a certain level of quality that resists fatigue.

Prefabrication Quality

Prefabrication is not just a buzzword. A controlled environment lets you apply consistent weld procedures, track every material batch, and run quality control tests in-house. This level of precision greatly lowers the risk of hidden defects that could become fatigue crack initiators. Red River LLC, for example, uses advanced BIM modeling to identify potential design conflicts, ensuring smoother assembly and fewer onsite adjustments. By the time your vessel or skid is delivered, it is nearly plug-and-play.

Thorough Documentation and Traceability

A big part of effective fatigue failure analysis is being able to trace material origins and workshop processes. Specialists often come with robust QC and record-keeping systems. They document each weld, track who did it, and keep test reports on file. If a crack does surface, you can quickly trace its potential cause. You will know exactly which process or batch of material might have contributed, simplifying your corrective actions.

Safety Culture

Fatigue is not only a technical issue, it is a people issue. If your operator or welding team is unaware of how critical a small defect can become over countless cycles, mistakes can slip through. Companies like Red River LLC prioritize safety, from top-tier training programs to open communication among crew members. This shifts the culture toward early detection and intervention of problems. Everyone from the floor welder to the project manager understands the importance of each step in the process.

Real-world Examples

- Multi-phase separators for oil and gas: Red River LLC has built these vessels for major operators worldwide, designing them for enormous internal pressures and temperature swings. Such conditions make fatigue a prime concern, so each vessel is thoroughly tested before leaving the shop.

- Water treatment solutions: Filtration vessels often run day and night, subjecting them to thousands of pressurization cycles. With specialized design and careful welding, you can extend their service life and reduce mid-cycle failures.

Encouraging note: Rest assured, if you choose a partner with the right credentials and track record, you are not alone. Teams dedicated to top-tier pressure vessel manufacturing have faced these challenges before. They know what it takes to keep your equipment safe and running longer.

The Importance of Fatigue Failure Analysis in your Next Project

Fatigue failure analysis matters because it helps you see what is really happening beneath the surface of your equipment. Tiny cracks might remain dormant for years, but under cyclical stress, they can suddenly become a life-threatening issue. By studying your vessel’s stress history, doing periodic inspections, and following recommended design guidelines, you substantially lower the odds of an unexpected shutdown.

This focus on fatigue goes beyond textbook theory. Whether you oversee oil and gas units, water treatment vessels, or any pressurized system, identifying early fatigue damage can mean the difference between smooth operations and major headaches. Fortunately, you do not have to tackle this alone. Many certified manufacturers offer comprehensive support, from conceptual design to final inspection. Pair that expertise with a practical approach to maintenance, and you will have a vessel that endures long after others have failed.

Good news, you can take steps today to reinforce your system against fatigue. Evaluate your equipment, prioritize inspections, and consult professionals if you suspect hidden cracks. Over time, you will see the rewards: safer operations, lower maintenance costs, and improved confidence in your industrial processes.

Take Action with Fatigue Failure Analysis

Don’t wait until small cracks lead to major failures. Partner with specialists like Red River LLC to ensure your pressure vessels and modular skids meet the highest safety and reliability standards. Get in touch today to safeguard your investment and protect your team.

Frequently Asked Questions

1. What is fatigue failure analysis

Fatigue failure analysis is the process of examining materials or components that have fractured due to repeated or cyclic stress over time. It identifies the causes, mechanisms, and contributing factors of fatigue to prevent future failures.

2. How to perform fatigue failure analysis

Fatigue failure analysis typically involves visual inspection, fractography using microscopes, material testing, and stress analysis. Engineers also review loading history, environmental conditions, and perform simulations to identify the root cause.

3. Why is fatigue failure analysis important

Fatigue failure analysis is important because it helps prevent unexpected breakdowns in structures or machinery, improves safety, and guides better material selection and design to extend service life.

4. What causes fatigue failure in materials

Fatigue failure is usually caused by repeated or fluctuating stresses below the material’s yield strength, often initiated at surface defects, stress concentrations, or poor design features.

5. How can fatigue failure be prevented

Fatigue failure can be prevented by improving design to reduce stress concentrations, using higher-quality materials, applying surface treatments, and conducting regular inspections and maintenance.

Key Takeaways

- Fatigue accumulates over repeated stress cycles, often lurking unseen until a crack becomes serious.

- Proper material selection and smart design can significantly reduce fatigue risk.

- Regular inspections, including non-destructive testing, detect early signs of cracking.

- Prefabrication in a controlled environment can address many weld-related fatigue trouble spots.

- Working with an ASME-certified specialist supports long-term reliability, thanks to stricter quality control and safety culture.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

- What is Fatigue Failure Analysis? Red River LLC

- Why is Structural Failure Analysis Important? Red River LLC

- Understanding Structural Failure Analysis for Pressure Vessels

- Corrosion Failure Analysis Explained

- Metallurgical Failure Analysis Guide Red River LLC

- Mechanical Failure Analysis for Reliability| Red River LLC

About Author