Water contamination in fuel causes corrosion, engine failure, and costly downtime. Understanding how does a fuel filter vessel water separator work helps protect equipment, extend maintenance intervals, and improve performance.

How Does a Fuel Filter Vessel Water Separator Work in Practice

Clean fuel is essential, but water contamination can cause corrosion, clogs, and higher maintenance costs. Industries like power generation, oil and gas, and transportation face this issue daily, making fuel filter vessel water separators vital. Many professionals ask, “how does a fuel filter vessel water separator work?”. The answer lies in its ability to remove water from fuel before it reaches the engine, ensuring smooth operation, protecting equipment, and cutting downtime. These systems remove water to keep engines running smoothly, protect equipment, and cut downtime. With advanced designs and prefabrication methods like those used by Red River Team, separation systems are now more reliable and easier to maintain or select for your needs.

Understand Fuel Contamination

Water can enter fuel during transport, storage, or from condensation, forming tiny droplets that regular filters often miss. This leads to two main problems: corrosion, which damages metal components and adds rust particles to the fuel, and poor engine performance, as water disrupts combustion, reducing power and efficiency. A fuel filter vessel water separator targets both droplets and vapor, lowering corrosion risk, improving efficiency, and reducing costly downtime.

How Does a Fuel Filter Vessel Water Separator Work

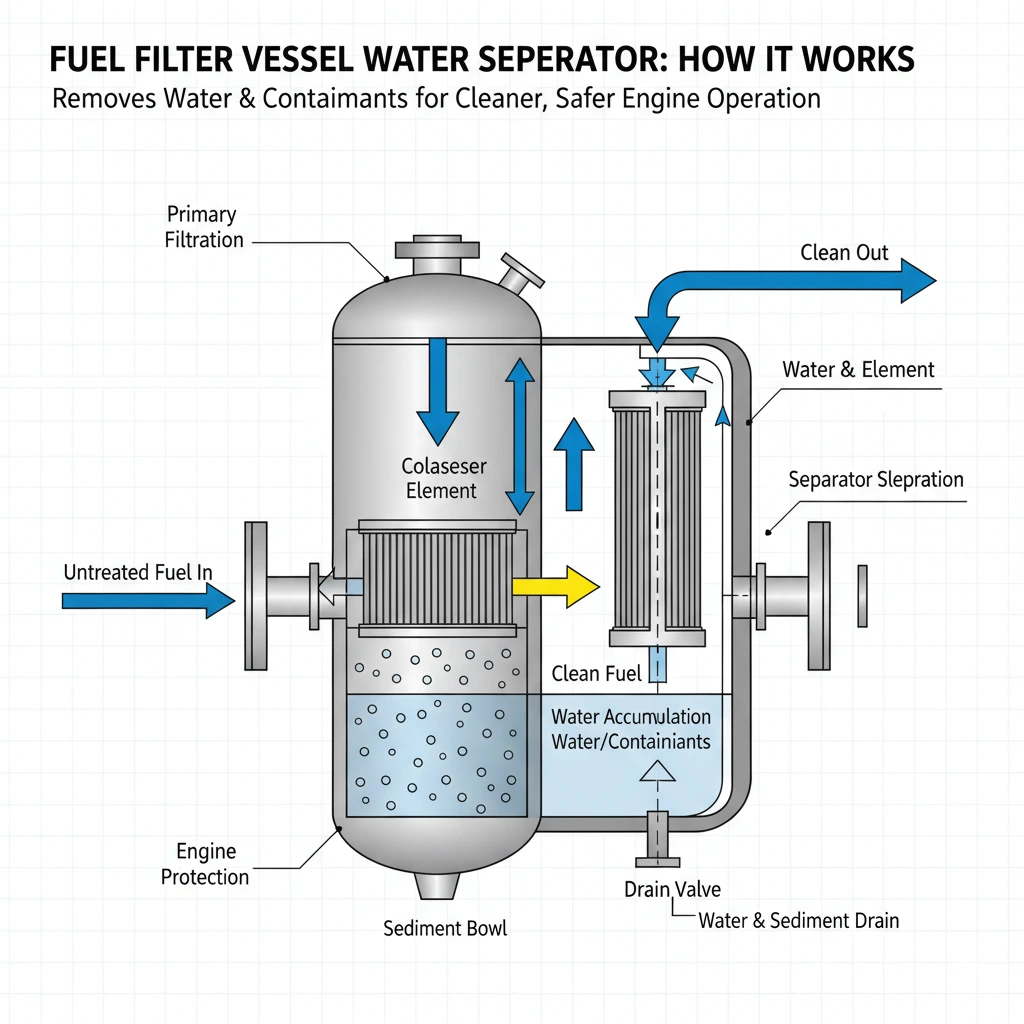

Although the name sounds technical, these systems use a straightforward process to extract water from the fuel stream. Here is the general way they operate:

Inlet Flow and Particle Filtration

You feed your fuel into a pressure vessel. At this stage, large solids drop out of the flow due to gravity or through an initial filter element. Heavy particulates sink or get trapped, which already improves fluid quality.

Coalescing Phase

Next, the fuel encounters coalescing media. Coalescing means tiny droplets of water come together, forming larger droplets. When water droplets become bigger, they are much easier to separate. This phase depends on specialized filter elements with materials that cause water droplets to merge and grow.

Separation Phase

Once you have larger droplets, gravity again comes into play. These heavier water droplets drop away from the lighter fuel. The separator material is engineered to repel water, so the fuel passes through while the collected water remains behind in a sump or drain section of the vessel.

Drainage and Disposal

The separated water accumulates at the base of the vessel. Some systems have automatic drain valves, while others require a manual drain. Either way, the final step is removing water so it never reenters the fuel.

Overall, the system prevents water from recirculating, which helps you maintain a higher purity level in your fuel lines. Designs vary in complexity, from basic two-stage units to more advanced multi-stage systems. For added assurance, you might also consider spares or parallel installations if your process demands consistent flow at all times.

Consider Design Essentials

Choosing the right fuel filter vessel water separator can feel overwhelming, but a few basic features stand out:

Vessel Configuration

Fuel separator vessels typically come in vertical or horizontal orientations. Vertical vessels can be space-efficient in tight facilities, while horizontal ones sometimes provide more extended separation time. In practice, you should match the orientation to your available floor space and flow rate requirements.

Flow Capacity

Each vessel is rated for a specific flow range. Oversized equipment can lead to unnecessary costs and too much contact time, while undersized vessels might struggle to separate water thoroughly at higher flow rates. You need to confirm your maximum system flow and find a separator designed to handle it efficiently.

Quality Standards

Using a certified vessel, such as an ASME pressure vessel separator, reassures you that it was built and tested to a recognized code. Red River Team, for example, ensures every vessel meets or exceeds the required ASME standards. This includes consistent material traceability, precise welds, and thorough inspection before shipping.

Filtration Media

The heart of coalescing and separation lies in the filter elements. Different media target different contaminant types, so choose the right one for your application. For instance, if you need a robust design for diesel systems, you may want to see our related piece on a diesel pressure vessel filter separator.

Maintenance Access

A user-friendly design includes easy access to the internal filter elements and a straightforward drain system for water removal. A vessel with top or side manways will simplify cleaning and inspection. Maintenance downtime can be considerably reduced when you do not have to disassemble half the system just to swap out a filter.

Focus on Prefabrication Benefits

When searching for a reliable fuel separation system, you might see references to prefabrication. Prefabrication simply means your equipment, piping, and essential components are assembled and tested off-site in a controlled environment. Companies like Red River Team lean on this approach, because it speeds up production and ensures consistent quality. A few advantages include:

- Reduced onsite labor: Prefabricated assemblies arrive mostly or fully complete, so on-site installation requires fewer workers, less setup time, and often less specialized tooling.

- Shorter project timelines: Weather delays, shipping inefficiencies, and last-minute hold-ups happen less frequently when major parts are built indoors. As a result, you can deploy your new fuel water separator quickly.

- Enhanced quality control: When everything is manufactured and inspected in one facility, it is easier to follow a rigid Quality Control process. For instance, Red River insists on an ASME Authorized Inspector to sign off on each vessel before it leaves the plant.

- Safer working environment: Prefabrication reduces on-site exposure hours, which lowers risks for your employees. The fewer tradespeople you have working in unpredictable conditions, the fewer incidents you are likely to have.

Prefabrication in Action

Imagine building a new fuel separator system in a busy industrial plant. On-site, you deal with cramped quarters, shift changes, and the unpredictable weather if the location is partially exposed. With prefabrication, the entire vessel (including internal piping and structural elements) is constructed in a controlled shop environment. Extensive tests—like pressure checks and weld inspection, are carried out ahead of schedule. Once the equipment arrives, installers align it, bolt it down, and finalize integrations. This approach can cut project time significantly and help you avoid rework.

How Does a Fuel Filter Vessel Water Separator Work for Better Reliability

It all comes down to removing water through coalescence, separation, and drainage. By investing in an ASME-certified separator built with prefabrication, you secure cleaner fuel, longer-lasting engines, and fewer water-related failures.

Every facility is unique consider flow rates, space, and risk tolerance when choosing your vessel. With proper planning, you’ll enjoy consistent performance and reduced downtime.

Protect Your Equipment with RedRiver LLC

At RedRiver LLC, we specialize in designing and delivering solutions that ensure your fuel stays clean. Contact us today to learn more about installing a fuel filter vessel water separator that keeps your operations efficient.

Frequently Asked Questions

1.What is a fuel filter vessel water separator

A fuel filter vessel water separator is a device in a fuel system designed to remove both solid contaminants (like dirt or rust) and water (in droplet or free form) from fuel before it reaches the engine. It uses a filter medium plus a vessel or chamber where water collects at the bottom and can be drained or removed.

2. Why use a fuel filter vessel water separator

Using a fuel filter vessel water separator protects engine components from corrosion and damage caused by water, ensures more reliable combustion and performance, reduces maintenance costs, and prevents downtime caused by contaminated fuel.

3. How does a fuel water separator differ from a regular fuel filter

A fuel water separator is built not only to trap solid particles but also to separate and remove water from fuel by exploiting difference in density and sometimes using hydrophobic media; a regular fuel filter usually only removes solids.

4. When should a fuel water separator be drained or serviced

It should be drained whenever visible water accumulates in the collection part and checked according to manufacturer service intervals; failure to do so can lead to water entering the engine or clogging filters.

5. What are the signs that a fuel water separator is failing

Poor engine performance, hard starting, frequent filter clogging, water in fuel sensor warnings, visible water in the fuel bowl or separator chamber are indicators the separator may be failing.

Key Takeaway

- Fuel contamination from water is a common threat to engine health and efficiency.

- A filter vessel separator focuses on trapping, merging, and draining water droplets.

- Vessel design, flow capacity, and certification are all key when choosing a solution.

- Prefabrication methods create reliable, consistent, and faster-to-install fuel systems.

- Targeted maintenance, including timely draining and filter checks, keeps your system running smoothly.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author