Pressurizing a pressure vessel involves carefully filling it with gas or liquid at high pressure using pumps or compressors, while ensuring safety through constant monitoring and adherence to engineering standards. The process requires proper sealing, pressure relief mechanisms, and trained operators to maintain the pressure vessel’s integrity. Pressure vessel pressurization is critical to safe operation across industries, from petrochemicals to pharmaceuticals.

Insight into Pressurizing a Pressure Vessel

Pressure vessels play a pivotal role across various industries such as petrochemicals, power generation, pharmaceuticals, and food processing. These highly engineered containers are designed to safely store and process gases and liquids under extreme pressure, sometimes far exceeding the pressure exerted by the environment surrounding them. The pressurization process, however, requires meticulous control, strict adherence to safety protocols, and comprehensive engineering knowledge to ensure the vessel operates efficiently without compromising safety or structural integrity.

What’s a Pressure Vessel?

In simple terms, a pressure vessel is a robust container designed to hold gases or liquids at pressures that are significantly higher than atmospheric pressure. The purpose of a pressure vessel is not just to store or transport substances but to do so in a way that prevents any structural failure. From holding superheated steam in power plants to containing dangerous gases in chemical processing plants, these vessels must be able to withstand intense internal pressure without compromising their structural integrity.

The Pressurization Process

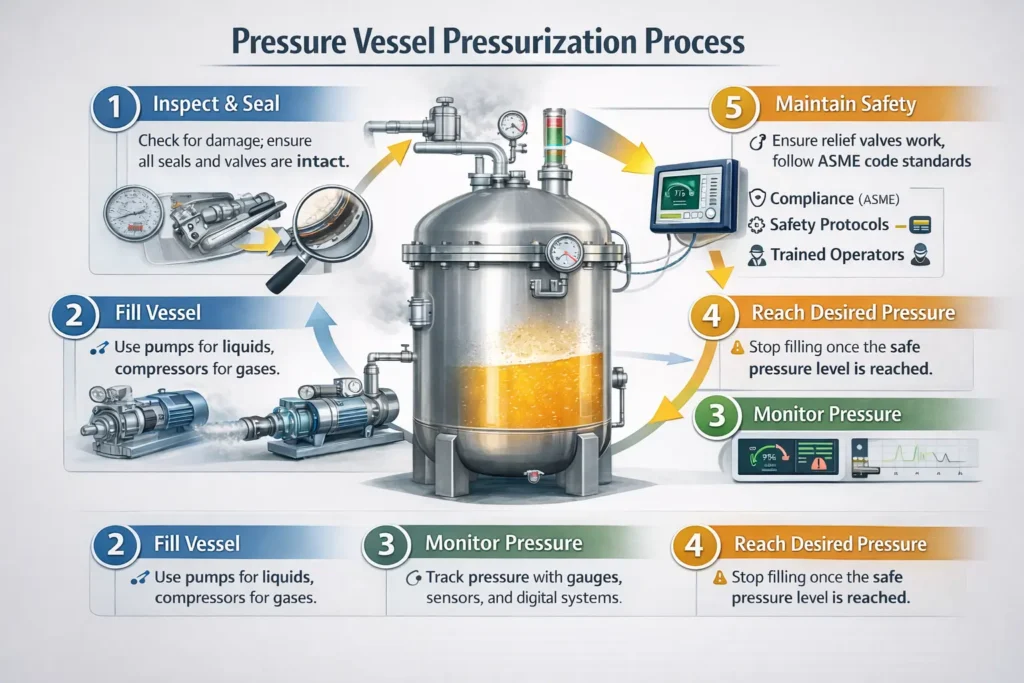

The process of pressurizing a pressure vessel is far from being a simple filling operation. It requires precise control and understanding of several critical factors to ensure both safety and efficiency. The pressurization process can be broken down into several stages, each with its own unique challenges:

1. Assessing the Pressure Vessel

Before beginning the pressurization process, it is essential to assess the vessel thoroughly. This includes inspecting the vessel for any signs of damage, wear, or corrosion, which could compromise its ability to safely contain high-pressure substances. Regular inspections, including visual checks for cracks, rust, or any deformities, are critical in preventing catastrophic failures.

2. Ensuring Proper Sealing

A pressure vessel’s success hinges on the integrity of its seals, gaskets, and valves. If these components are damaged or improperly installed, they can lead to dangerous leaks. Regular checks on the gaskets and valves ensure they are functioning correctly, preventing accidents during pressurization. The pressure relief valves should be tested to ensure they open correctly under excess pressure to prevent any over-pressurization incidents.

3. Filling the Vessel with the Desired Substance

Once the vessel is inspected and all seals are confirmed to be intact, the next step is to fill the vessel with the gas or liquid that it is designed to hold. The method of pressurization depends on the type of substance involved.

- For Liquids: Pumps are typically used to fill the vessel, as liquids cannot be compressed in the same way gases can. Liquid pressurization is straightforward, relying on the pump to move the liquid at a high rate into the vessel.

- For Gases: Compressors are the tools of choice. Gases are compressible, so a compressor works by drawing in the gas, compressing it to the desired pressure, and then injecting it into the vessel.

4. Monitoring Pressure Levels

During pressurization, constant monitoring is essential. Operators must use pressure gauges, sensors, and digital monitoring systems to keep a close watch on the internal pressure. Automated systems and real-time data feeds allow operators to intervene at the first sign of irregularities, such as unexpected pressure fluctuations, leaks, or malfunctions. Monitoring systems also help ensure that the pressure remains within safe levels and that any unexpected spikes or drops in pressure are addressed immediately.

5. Reaching the Desired Pressure

Once the vessel reaches the desired pressure, the pressurization process is halted, and the vessel is sealed off. The pressure should stabilize naturally without fluctuation, finding an equilibrium that ensures safety without exceeding the maximum allowable pressure set by design standards. The system should be able to maintain the pressure without undue stress on the vessel materials.

Safety Considerations

Pressure vessels operate under strict safety protocols due to the inherent risks of over-pressurization, including rupture or explosion. Ensuring that the vessel remains within the prescribed limits is paramount:

- Safety Margins: ASME (American Society of Mechanical Engineers) standards for pressure vessels require that the vessel’s maximum allowable working pressure (MAWP) must be established during the design phase. This ensures that the vessel can operate safely under high pressure without reaching the point of failure.

- Pressure Relief Mechanisms: Pressure relief valves and burst discs are installed as fail-safes to release excess pressure and avoid catastrophic failures.

- Regular Maintenance: Preventative maintenance, including pressure checks and equipment inspections, is vital to ensure that the pressure vessel remains in optimal condition over its operational lifespan.

Letting Off Steam

When it’s time to reduce the internal pressure, operators should proceed carefully

- Release Pressure Gradually: Release pressure slowly through the designated valves to avoid any sudden shock or stress on the vessel.

- Monitor the Drop: As pressure drops, it is important to monitor the process to ensure that it is done gradually, preventing any abrupt fluctuations that could damage the vessel.

The Importance of Skilled Operators

A crucial aspect of the pressurization process is ensuring that operators are well-trained in both the operational and safety aspects of pressure vessels. Operators should be familiar with the latest industry standards and technologies, as well as best practices for handling these complex systems. Ongoing training is essential to maintaining safety and operational efficiency.

Case Study: Red River’s Pressure Vessel Solutions

At Red River, we specialize in the design and manufacturing of pressure vessels tailored to meet the specific needs of various industries. For example, in one recent project for a chemical processing plant, we designed a custom composite pressure vessel that not only met rigorous industry standards but also incorporated advanced monitoring systems to ensure safe operation under fluctuating environmental conditions. The success of this project demonstrated our commitment to safety, innovation, and precision in every aspect of pressure vessel design and manufacturing.

Ensuring Safe and Efficient Pressure Vessel Pressurization

The process of pressure vessel pressurization is critical in maintaining safety, efficiency, and operational integrity across industries. By following precise protocols, using the correct equipment, and ensuring continuous monitoring, pressure vessels can be safely filled with gases or liquids without compromising safety. As we’ve outlined, it is essential to inspect and seal the vessel, properly monitor the pressure, and maintain strict adherence to compliance standards such as ASME to avoid failures. Ensuring safety mechanisms like pressure relief valves and proper operator training further protects against potential hazards.

Contact Red River Today: Your Trusted Partner in Pressure Vessel Solutions

Ready to ensure your pressure vessels are designed and pressurized to the highest safety standards? At Red River, we specialize in the design, manufacture, and maintenance of pressure vessels that meet industry-leading safety protocols. Whether you’re in the petrochemical, pharmaceutical, or food processing industry, we provide reliable, durable, and expertly crafted solutions tailored to your needs.

Contact Red River today to discuss how we can support your pressure vessel requirements and help you achieve safety and efficiency in your operations. Let us be your trusted partner in keeping your operations running smoothly and safely!

Frequently Asked Questions

1. What is the process of pressurizing a pressure vessel?

Pressurizing a pressure vessel involves filling it with a gas or liquid at a pressure higher than the ambient pressure, using pumps for liquids and compressors for gases. Safety valves are essential to prevent over-pressurization.

2. How do you determine the appropriate pressure level for a pressure vessel?

The appropriate pressure level is based on the vessel’s design, material, and intended use. The maximum allowable working pressure (MAWP) is calculated by engineers during the design phase.

3. What safety mechanisms are in place during the pressurization of a pressure vessel?

Safety mechanisms include pressure relief valves, burst discs, regular inspections, and automated monitoring systems to detect pressure anomalies.

4. Can pressure vessels be pressurized with any type of gas or liquid?

The compatibility of a pressure vessel with specific gases or liquids depends on its construction material and design.

5. What are the common challenges faced during the pressurization of pressure vessels?

Challenges include managing thermal expansion, avoiding corrosion, and ensuring uniform pressure distribution.

Key Takeaways

- Safety First: Always conduct comprehensive inspections and ensure proper sealing of gaskets and valves before pressurization begins.

- Right Tools Matter: Use pumps for liquids and compressors for gases, and make sure the appropriate tool is selected based on the substance being pressurized.

- Constant Monitoring: Use sensors, gauges, and digital systems to continuously monitor internal pressure levels.

- Compliance: Adhere to industry standards and local regulations for safe operations.

- Skilled Operators: Regular training ensures operators maintain safe and efficient pressure vessel pressurization processes.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No subpillar set for this blog post.