Introduction to Pressure Vessel Design

The production of a pressure vessel is a meticulous procedure, one which we at Red River take extraordinary delight in. Our vessels are greater than just metallic structures; they are the result of superior engineering and specific fabrication strategies. We focus on vessels with hemispherical ends, a layout choice that’s no longer just aesthetically alluring but additionally scientifically sound. The hemispherical shape presents an advanced distribution of pressure, lowering the chances of pressure-related failures. This design is a testament to our dedication to no longer most effectively meet but exceed enterprise requirements.

Importance of Design in Pressure Vessel Safety

Safety isn’t just a phrase at Red River; it’s a mantra that guides each step of our production system. The design of a pressure vessel plays a pivotal position in its protection. Hemispherical ends, for example, aren’t just a design desire but a safety characteristic. They dispose of sharp corners, lowering pressure concentrations and considerably decreasing the danger of cracks and structural failures. This design, coupled with our rigorous first-class control measures, ensures that each vessel we produce isn’t always just compliant but a benchmark in protection.

Overview of Different Pressure Vessel End Shapes

While hemispherical ends are our specialty, we understand that distinct packages may also require exceptional designs. That’s why we provide several ranges of end shapes, which include elliptical and flat. Each layout has its precise blessings and is selected based totally on the precise needs of the software. Our crew of experts is adept at reading those necessities and advising at the best cease to form, making sure that your pressure vessel isn’t just a product but a tailor-made answer.

The Science Behind Hemispherical Ends

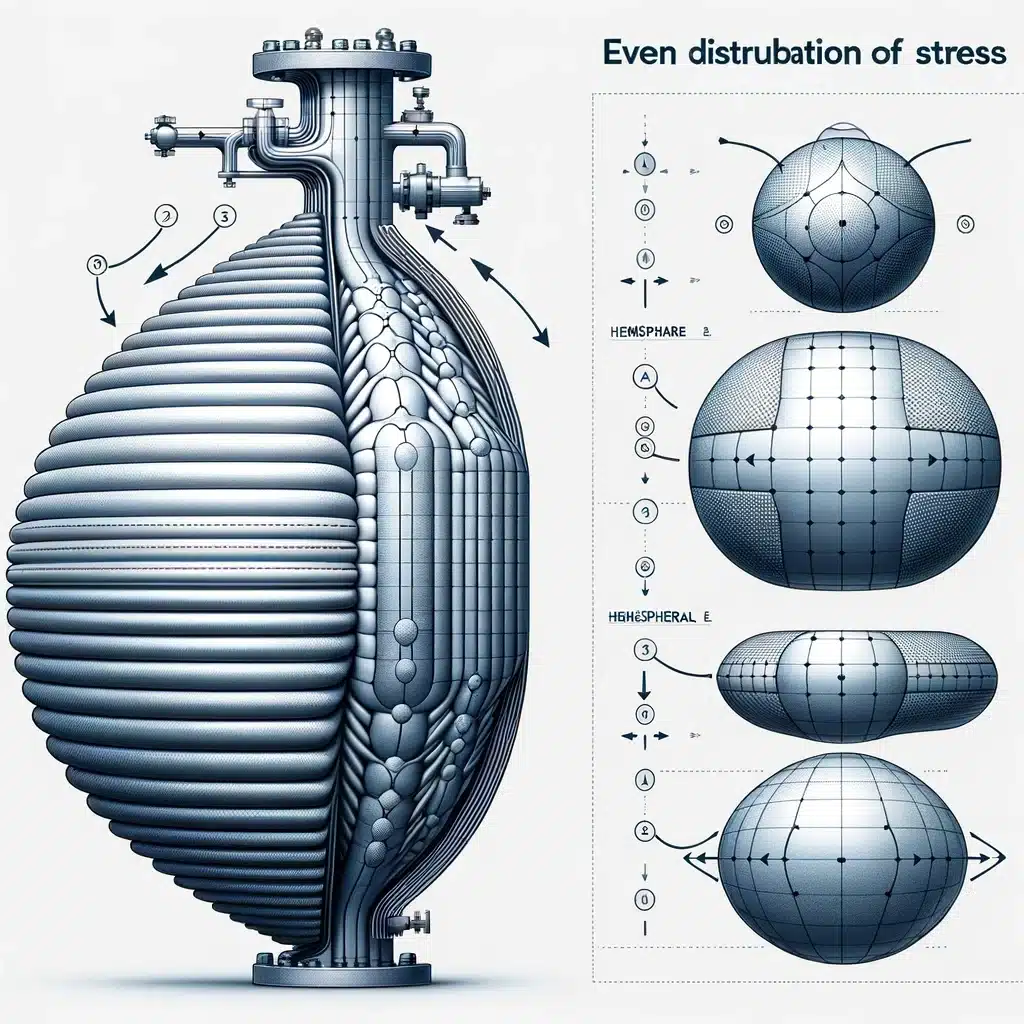

Stress Distribution in Hemispherical Designs

Hemispherical results in pressure vessels provide advanced pressure distribution. This form lightly disperses pressure across the vessel’s surface, minimizing pressure concentrations which can result in material fatigue and failure.

Comparing Hemispherical and Flat-End Stress Factors

Compared to flat ends, hemispherical designs substantially lessen pressure factors. The curved surface of a hemispherical cease withstands better pressure ranges more efficiently, enhancing the vessel’s universal structural integrity.

Material Efficiency in Hemispherical Pressure Vessels

Hemispherical vessels utilize substances more effectively. Their design requires much less thickening at the rims, lowering fabric utilization even as keeping strength and sturdiness.

Advantages of Hemispherical Ends in Pressure Vessels

Enhanced Durability and Safety

The hemispherical layout inherently complements sturdiness and safety. Its potential to lightly distribute pressure results in a lower risk of cracks and leaks, making sure a more secure operation surroundings.

Improved Pressure Distribution

Hemispherical ends ensure a more uniform pressure distribution within the vessel. This uniformity is crucial for retaining structural integrity under excessive pressure situations.

Cost-Effectiveness of Hemispherical Design

The hemispherical layout is not only structurally effective but also powerful. It calls for less clothing and maintenance, main to long-term financial savings.

Historical Development of Pressure Vessel Designs

Evolution from Flat to Hemispherical Ends

The evolution from flat to hemispherical ends marks a sizeable advancement in pressure vessel layout, prioritizing safety and performance.

Milestones in Pressure Vessel Engineering

Key milestones in pressure vessel engineering were pushed through the want for more secure, extra green designs, with hemispherical ends being a prime instance.

Case Studies: Historical Pressure Vessel Failures

Historical disasters in pressure vessels have underscored the significance of the foremost design, in particular the shift towards hemispherical ends for better pressure control.

Engineering Principles of Hemispherical Vessel Ends

Geometric Analysis of Hemispherical Shapes

Geometric evaluation of hemispherical shapes is famous for its advanced ability to face up to internal pressures in comparison to different designs.

The Role of Curvature in Pressure Resistance

The curvature of hemispherical ends plays an essential role in improving pressure resistance, distributing pressure greater evenly across the vessel.

Material Selection for Hemispherical Ends

Selecting the right material for hemispherical ends is critical for maximizing their efficiency and longevity under various pressure situations.

Manufacturing Processes for Hemispherical Ends

Fabrication Techniques for Hemispherical Shapes

Advanced fabrication techniques are hired to create hemispherical shapes, ensuring precision and exceptional in each vessel.

Quality Control in Hemispherical End Production

Stringent nice manipulation measures are in the region for the duration of the manufacturing of hemispherical ends, ensuring adherence to protection and enterprise standards.

Innovations in Manufacturing of Pressure Vessels

Continuous innovations in manufacturing methods replicate our dedication to generating the maximum reliable and green pressure vessels in the industry.

Real-World Applications of Hemispherical Pressure Vessels

Hemispherical Vessels in the Chemical Industry

In the chemical industry, hemispherical pressure vessels are critical for properly coping with high-pressure reactions, ensuring stability and reliability in volatile environments.

Role in Energy Sector and Power Plants

These vessels play a critical role inside the strength zone, in particular in strength flowers, where they are used for steam technology and gasoline garages under high pressures.

Use in Aerospace and Submarine Applications

Hemispherical pressure vessels are fundamental in aerospace and submarine programs, imparting superior resistance to outside pressures and cruel environments.

Comparing Hemispherical and Other End Cap Designs

Hemispherical vs. Elliptical Pressure Vessel Ends

Hemispherical ends are often compared to elliptical ends, with the previous supplying better pressure distribution and the latter providing a lower profile.

Pros and Cons of Various End Cap Designs

Different stop cap designs have their specific blessings and obstacles, with hemispherical ends often leading in phrases of sturdiness and safety.

Case Studies: Performance Comparison

Case studies show that hemispherical designs regularly outperform other shapes in high-pressure situations, validating their preference in critical packages.

Maintenance and Inspection of Hemispherical Pressure Vessels

Routine Maintenance Practices

Regular upkeep of hemispherical vessels is crucial for toughness, concerning inspections for corrosion, put-on, and pressure integrity.

Inspection Techniques for Hemispherical Ends

Specialized inspection techniques are hired for hemispherical ends, focusing on their specific curvature and pressure factors.

Longevity and Lifecycle of Hemispherical Vessels

The layout of hemispherical vessels contributes to their extended lifecycle, reducing the frequency and price of replacements.

Future Trends in Pressure Vessel Design

Innovations in Hemispherical End Design

Ongoing innovations in hemispherical give up design recognition on improving fabric efficiency and adapting to new energy sources.

Emerging Materials and Technologies

The destiny of pressure vessel design lies in the adoption of rising substances and technologies, aiming for better performance and environmental sustainability.

Predictions for Future Pressure Vessel Developments

Predictions for future trends consist of smarter, greater adaptable vessels that can cope with a much wider variety of pressures and mediums.

Why Choose Red River LLC for Your Pressure Vessel Needs

Our Expertise in Hemispherical Pressure Vessel Design

Red River LLC stands out for its expertise in hemispherical pressure vessel design, presenting unparalleled protection and performance.

Custom Solutions and Services Offered

We offer custom answers tailored to particular industry wishes, subsidized via a crew of experts devoted to delivering excellence.

Commitment to Quality and Safety Standards

Our unwavering commitment to exceptional protection standards ensures that each vessel we produce meets the highest industry benchmarks.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions About Pressure Vessels

What are the key factors to consider when selecting materials for pressure vessels?

When selecting materials for pressure vessels, it is crucial to take into account factors like the working temperature, pressure situations, the chemical nature of the contents, corrosion resistance, and the vessel’s supposed lifespan. Materials typically used encompass carbon metallic, stainless steel, and alloys like Hastelloy, Inconel, and Monel, every offering distinct blessings in phrases of strength, corrosion resistance, and fee effectiveness.

How do pressure vessel design standards ensure safety and reliability?

Pressure vessel design requirements, consisting of the ones set with the aid of the American Society of Mechanical Engineers (ASME), provide a complete framework for safety and reliability. These standards cover components like cloth selection, layout, fabrication, inspection, and testing. They ensure that vessels can withstand the operational pressures and temperatures, prevent failures, and defend both the team of workers and the surroundings.

What are the differences between vertical and horizontal pressure vessels, and how does orientation impact performance?

The orientation of a pressure vessel, whether vertical or horizontal, influences its performance and suitability for precise applications. Vertical vessels generally require much less floor space and are better for isolating liquids from gases due to gravity. Horizontal vessels, then again, offer less difficulty to get the right of entry for maintenance and are preferred for storing liquids. The desire relies upon elements like area constraints, phase separation needs, and simplicity of maintenance.

Can pressure vessels be customized for specific industrial applications, and what are the common customizations?

Yes, pressure vessels can be distinctly customized to satisfy particular business desires. Common customizations consist of varying the dimensions and shape, including internal components like baffles or liners, incorporating unique inlet and outlet configurations, and applying specialized coatings for corrosion resistance. These customizations permit vessels to efficaciously deal with unique operational requirements, consisting of high-pressure reactions, temperature management, or corrosive substances.

What are the emerging trends and technologies in pressure vessel manufacturing, and how are they enhancing performance?

Emerging trends in pressure vessel production consist of the use of advanced substances like composites and excessive-strength, lightweight alloys, which provide advanced performance under severe conditions. Technological improvements like 3-D printing and automatic welding are enhancing production precision and efficiency. Additionally, the mixing of smart sensors and IoT generation is allowing real-time monitoring of vessel situations, leading to predictive renovation and improved safety.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author