Pressure tanks play a vital role in regulating water systems across residential, agricultural, and industrial applications. Choosing the right type diaphragm, bladder, or air over water pressure tank is essential to ensure efficiency, longevity, and ease of maintenance.

At Red River, we specialize in high-performance pressure vessels designed to meet your system’s specific requirements. This guide breaks down each type so you can make an informed decision.

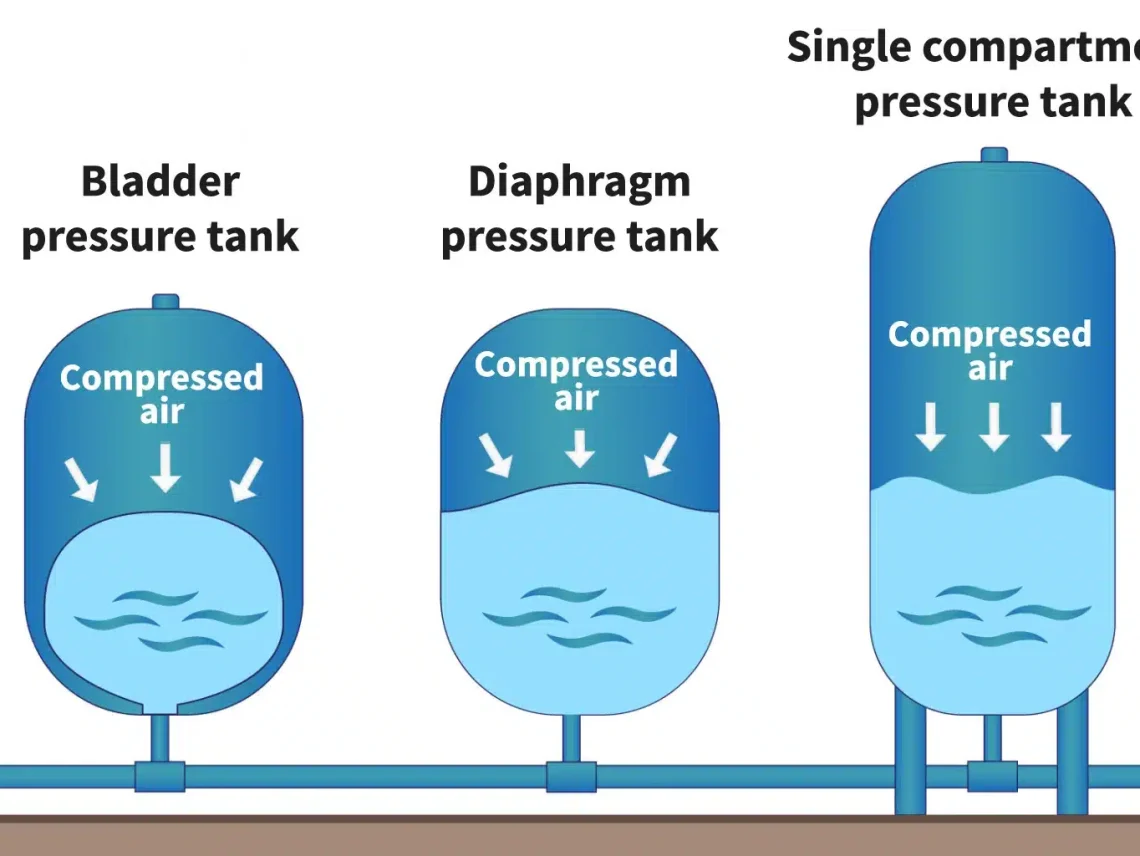

All pressure tanks serve the same fundamental purpose: maintaining consistent water pressure and preventing pump overwork. However, how they separate air and water determines their performance and maintenance profile. Among them, the air over water pressure tank is the simplest, yet often overlooked option.

Diaphragm tanks contain a sealed rubber membrane that divides the water from the air. This design eliminates waterlogging and offers low-maintenance operation.

Best for: Residential use, space-limited installations

Pros:

Minimal maintenance

Long-term durability

Steady pressure delivery

.

These tanks use a replaceable internal bladder, offering easy servicing and high efficiency, even in systems that cycle frequently.

Best for: Industrial and commercial water systems

Pros:

High efficiency

Replaceable internal parts

Long service life with proper care

The air over water pressure tank is a traditional design where water and air occupy the same chamber without a separating membrane. It’s budget-friendly but needs frequent air charging due to absorption into the water.

Best for: Low-cost installations, older or simpler systems

Pros:

Lower initial cost

Simple mechanical design

Easy access for maintenance

Cons:

Air dissolves into water over time

Requires regular monitoring and air replenishment

Many older homes still use an air over water pressure tank, but newer systems often favor diaphragm or bladder models due to lower maintenance demands.

A modern air over water pressure tank can still serve effectively in well water systems or rural installations where simplicity and accessibility matter. They’re especially attractive when the budget is limited, and system pressure needs are moderate.

However, if you’re considering upgrading your water system, weigh the long-term upkeep of an air over water pressure tank against the hands-off reliability of diaphragm or bladder tanks.

When selecting a pressure tank, here’s what to keep in mind:

Space constraints: Diaphragm tanks fit tight spaces.

Maintenance readiness: An air over water pressure tank needs more manual upkeep.

Performance demands: Choose bladder tanks for high-cycle systems.

Need help sizing the right tank? Visit our [Pressure Tank Sizing Guide].

If you’re leaning toward the air over water pressure tank, it’s a practical choice for basic systems but comes with more hands-on care. Diaphragm and bladder tanks are more advanced options with better long-term performance.

Ready to boost your system’s performance with the right pressure tank?

Get in touch with Red River now and let’s build the best solution for your needs.

Need expert advice on choosing the right pressure tank?

Talk to our team at Red River today let’s find the perfect solution for your system.

An air over water pressure tank is a basic type of pressure vessel where air and water share the same chamber. It’s cost-effective but requires regular air replenishment to maintain pressure.

Unlike bladder tanks, which use a rubber bladder to separate air and water, air over water pressure tanks allow direct contact between the two. This makes them simpler but less efficient over time due to air absorption.

Yes, while newer systems often use diaphragm or bladder tanks, air over water pressure tanks are still common in rural setups or legacy systems where cost and simplicity are priorities.

These tanks require periodic air recharging to compensate for air loss. Without regular checks, the system can become waterlogged and lose efficiency.

It depends. If you want a low-cost option and don’t mind occasional maintenance, it can work well. For more consistent performance with less upkeep, consider a diaphragm or bladder tank.

Diaphragm tanks offer minimal maintenance and long-lasting efficiency, ideal for residential systems.

Bladder tanks are highly efficient and suitable for demanding applications but require bladder replacements.

Air-over-water tanks are cost-effective and simple to maintain, though less efficient over time.

Choosing the right tank depends on system requirements, available space, and maintenance preferences.

Regular maintenance is essential for bladder and air-over-water tanks to ensure optimal performance.

Explore more resources to help you choose the right pressure tank for your system:

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.