How Water Scrubber Systems Work: Uses, Types & Optimization

Introduction: The Power of Water Scrubber Systems in Modern Industry

Clean air is a top priority in today’s industrial world, and water scrubber systems are essential for achieving this goal. Whether you’re in manufacturing, energy, or chemical processing, understanding how a water scrubber system works—and why it matters—can help you meet environmental standards, cut costs, and ensure workplace safety. In this guide, we’ll explore the science, benefits, and best practices of water scrubber systems. If you want to know how these powerful systems tackle industrial pollution, you’re in the right place.

Explore more about the role of water in scrubber vessel operations and why scrubber vessel cleaning is crucial for optimal performance.

What Is a Water Scrubber System?

A water scrubber system—sometimes called a wet scrubber—is a pollution control device designed to remove harmful substances like sulfur dioxide (SOx), particulate matter, and volatile organic compounds (VOCs) from industrial exhaust streams. The system passes contaminated gas through a water-based solution, which absorbs and neutralizes pollutants before releasing cleaner air.

Industries use water scrubber systems to comply with strict environmental regulations from agencies such as the U.S. Environmental Protection Agency (EPA) and the International Maritime Organization (IMO). To understand their industrial importance, see this deep dive on scrubber vessel technology.

Key Components & Operation

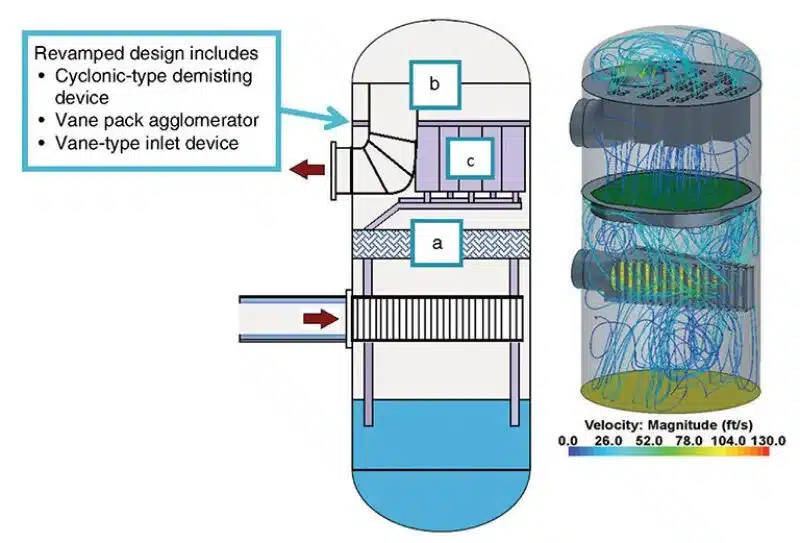

Every water scrubber system includes:

Inlet Duct: Where polluted air or gas enters.

Scrubbing Chamber: The heart of the system where gas meets the scrubbing liquid (usually water).

Mist Eliminator: Removes droplets before clean air exits.

Outlet Duct: Releases treated air into the environment.

Gas-Liquid Contact

The success of a water scrubber system depends on how effectively gas interacts with the scrubbing solution. This process allows pollutants to be absorbed, adsorbed, or chemically transformed. The result is cleaner emissions that comply with regulatory standards.

Explore more: Learn about how air quality scrubber vessels work and the significance of different types and applications of scrubber vessels.

Types: Wet vs Dry Scrubbers

Water scrubber systems are a category of wet scrubbers, but it’s helpful to compare them with dry scrubbers:

Wet Scrubbers: Use water or a liquid solution to remove gases and particulates. Best for controlling SOx, NOx, and soluble pollutants.

Dry Scrubbers: Use solid sorbents, ideal for applications where water use is limited.

Closed-loop and open-loop designs offer different advantages. Closed-loop systems recycle water for higher efficiency, while open-loop systems are simpler but use more water. Wikipedia’s overview covers the technical basics of both.

Applications & Industry Standards

Water scrubber systems are widely used in:

Power plants: Removing sulfur and nitrogen oxides from flue gas.

Marine vessels: Complying with IMO regulations on emissions.

Chemical processing: Controlling toxic releases.

Manufacturing: Keeping air safe for workers and the public.

Regulatory compliance is non-negotiable. Failure to use an effective water scrubber system can result in fines and environmental harm. See understanding scrubber vessels in the industry for sector-specific insights.

Optimization Tips for Maximum Efficiency

Get the most out of your water scrubber system by:

Monitoring pH and flow rates: Ensures pollutant removal efficiency.

Regular maintenance: Prevents build-up and system failures.

Upgrading to smart monitoring systems: Real-time adjustments mean higher efficiency.

Selecting the right system: Consider type, pollutant load, and installation needs.

For more on maximizing lifespan and performance, check out the importance of scrubber vessels.

Conclusion

Water scrubber systems are a proven solution for industrial air pollution control, helping organizations meet regulatory requirements and safeguard the environment. Investing in the right system and maintaining it properly pays off in cleaner air, safer workplaces, and regulatory peace of mind.

Call to Action

Ready to upgrade your pollution control or need expert advice on water scrubber systems? Contact Red River today to discover custom solutions for your operation.

FAQ Section

How does a water scrubber system work?

A water scrubber system uses water to absorb and neutralize pollutants from exhaust gases. Polluted air passes through a chamber, where contaminants dissolve or react in the water, resulting in cleaner emissions.

What types of pollutants can water scrubber systems remove?

These systems can remove sulfur dioxide (SOx), nitrogen oxides (NOx), particulates, and volatile organic compounds (VOCs).

What are the main types of water scrubber systems?

The main types are wet scrubbers (use liquids like water) and dry scrubbers (use solid sorbents). Wet scrubbers are more effective for gaseous pollutants.

What is the difference between closed-loop and open-loop systems?

Closed-loop systems recycle the scrubbing liquid, increasing efficiency and reducing water use. Open-loop systems discharge used water after one cycle.

How do I maintain a water scrubber system?

Regular inspection, cleaning, and monitoring of solution chemistry are essential. Upgrading controls can further enhance performance.

Are water scrubber systems required by law?

Can water scrubber systems reduce greenhouse gas emissions?

While primarily for air pollutants, some advanced systems help minimize emissions that contribute to climate change.

Where can I learn more about scrubber vessel technology?

See scrubber vessel technology for the latest in system innovations and best practices.

Key Takeaways

Water scrubber systems play a crucial role in removing harmful pollutants and meeting strict environmental standards in industrial settings.

Choosing the right type (wet vs. dry, closed-loop vs. open-loop) depends on your industry’s needs and compliance requirements.

Effective operation and regular maintenance are key to maximizing performance and minimizing downtime.

Optimizing system settings—like pH, flow rate, and automation—can significantly improve pollutant removal efficiency.

Internal and external links enrich your understanding and connect you to valuable resources and solutions.

Investing in a well-designed water scrubber system protects both your business reputation and the environment.

Related Blog Post

- Do scrubber vessels use water?

- What do scrubbers vessel clean?

- What do scrubbers remove 90% of?

- How do scrubber vessel clean the air?

- What are the three types of scrubber vessels?

- What is the industrial use of scrubber vessels?

- What are the advantages of a scrubber vessel?

- What are the pros and cons of a scrubber vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No pillar keyword set for this post.

About Author