A fuel oil pressure vessel separator removes water and impurities from fuel to improve engine efficiency, reduce downtime, and extend equipment lifespan. It uses gravity, coalescing media, and pressure control to keep fuel systems clean and reliable.

How Does a Fuel Oil Pressure Vessel Separator Work: Key Insights

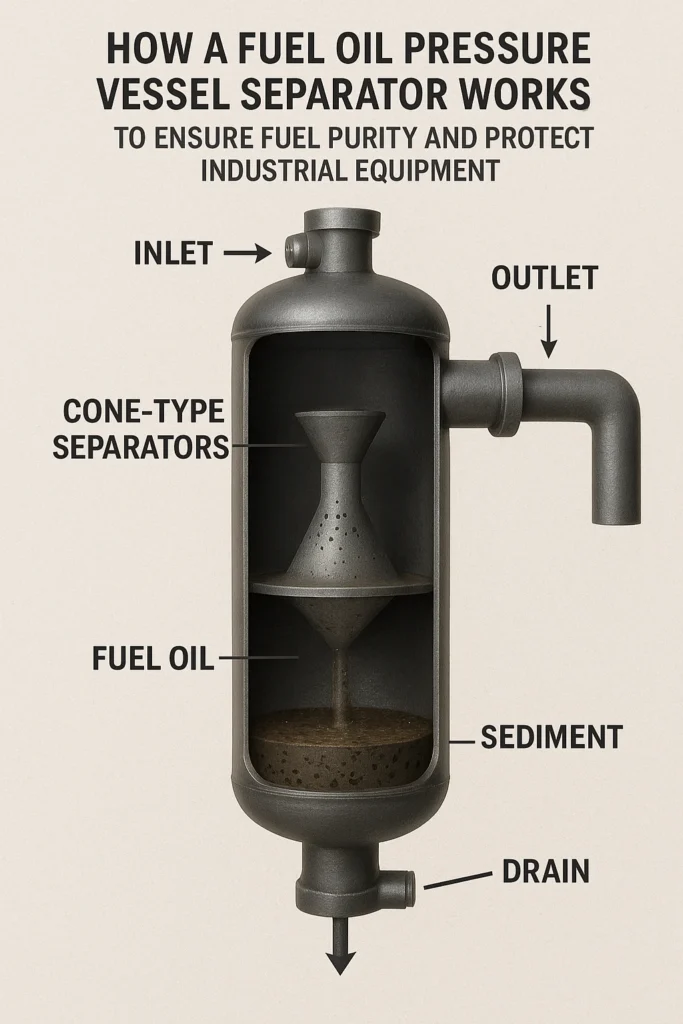

How does a fuel oil pressure vessel separator work? A fuel oil pressure vessel separator is a specialized tank designed to remove water and particulates from fuel through a series of filtration and coalescing stages. Essentially, it takes in a mix of liquids and possibly gases, then uses differences in density, gravity, and internal components to separate clean fuel from water or sediment. You might see similar principles in a diesel pressure vessel filter separator. Here is a quick, step-by-step look at the typical process:

- Inlet flow: Fuel enters the vessel through a carefully designed inlet. This inlet setup helps spread the fuel evenly within the vessel so separation can happen as efficiently as possible.

- Primary separation: As the fluid moves through the chamber, gravity begins to do the heavy lifting. Water droplets, which are denser than oil, start to settle at the bottom. Some vessel designs use baffles (internal plates) to reduce turbulence and encourage those droplets to drop out.

- Coalescing elements: Many separators include a coalescer. A coalescer is a layer of media that causes small water droplets to merge and form bigger droplets. Once they are bigger, they sink faster, leaving less water suspended in the fuel.

- Secondary separation: A demister or second coalescing stage can capture any remaining droplets of water. This step is especially helpful if the incoming fuel is heavily contaminated or if you need near-pristine quality for sensitive engines.

- Collection and discharge: The separated water or sludge drifts to a collection section. Once there, it is regularly drained off or piped away. Meanwhile, the clean fuel is drawn off at the top or from an outlet that sits above the separated water layer.

- Constant pressure control: The vessel is designed to handle operating pressures that keep fluid flow consistent. An internal or external control system ensures safe pressure levels, so you can efficiently process large amounts of fuel without risking leaks or damage.

A reliable fuel oil pressure vessel separator often meets ASME (American Society of Mechanical Engineers) standards, ensuring high-quality welds and materials that can tolerate your operating conditions. Red River, for instance, holds ASME certification and adheres to strict safety and quality checks to keep each separation unit performing at its best (Red River).

Identify Key Separator Components

To appreciate the day-to-day function of a fuel oil pressure vessel separator, it helps to know the essential parts at work. These elements combine to keep your fuel supply steady and your equipment in top shape.

Separation Chamber

The main body where separation occurs. Sized by flow and space needs, it slows fluid so heavier water and particles settle.

Inlet, Outlet, and Drain

Openings designed to minimize turbulence. Fuel enters smoothly, clean fuel exits without remixing, and separated water collects for easy removal.

Coalescer or Demister Pads

These trap and merge small droplets into larger ones to speed separation. They use mesh or specialized media that require cleaning or replacement.

Pressure-relief and Control Valves

Manage internal pressure to prevent over-pressurization and control fluid flow for optimal separation.

Safety Instrumentation

Includes gauges, alarms, and sensors that monitor pressure, temperature, and fluid levels, alerting operators to any issues.

Understand Important Benefits for Efficiency

You might wonder why a specialized separator is so critical when you can use basic filters. While standard filters do offer some defense against grit or small water droplets, they are usually not enough once water levels or contaminant risk climbs. Here is how a pressure vessel separator especially helps your bottom line:

Reduced Downtime

Separators prevent moisture from reaching engines, cutting corrosion and injector failures. Studies show they can reduce breakdowns by up to 25%.

Better Fuel Economy

Removing water and debris improves combustion, helping engines run cleaner and more efficiently, saving fuel over time.

Extended Component Life

Clean fuel protects pumps and injectors. Regular draining can extend equipment lifespan and reduce replacement costs.

Improved Safety

Contaminated fuel can cause misfires or steam buildup. A rated separator lowers these risks and supports safer operations.

Streamlined Operational Flow

Pressure vessels allow higher fuel flow without loss in efficiency, keeping fueling quick and consistent.

Faster Installs with Prefabrication

Prefabricated systems from companies like Red River offer better quality, quicker setup, and fewer site disruptions.

Practice Proper Operation and Maintenance

You might invest in the best separator on the market, but performance will slip if you do not maintain it. Fortunately, upkeep is straightforward as long as you follow these key steps:

Perform Regular Drain-offs

Routinely drain the sump to prevent water and solids from re-entering the fuel. Use sensors to get alerts when levels are too high.

Inspect Pressure Gauges

Check pressure weekly. Spikes or drops can signal blockages or valve issues—pause and inspect before problems grow.

Clean or Replace Coalescing Media

Follow the maintenance schedule to clean or swap the media. This keeps separation efficient and extends system life.

Monitor for Corrosion

Inspect the vessel regularly. Even certified units can corrode if water sits too long—early treatment prevents damage.

Schedule Routine Performance Tests

Test your fuel for water content to track separator performance. Adjust flow or maintenance if needed.

How Does a Fuel Oil Pressure Vessel Separator Work for Long-Term Reliability

A fuel oil pressure vessel separator removes water and contaminants using gravity, coalescing media, and steady pressure. Fuel enters through an inlet, water settles at the bottom, and clean fuel exits. Built to ASME standards, it ensures safe, efficient operation with regular maintenance.

For more details, explore the differences in an industrial fuel water separator vessel. Keeping your fuel free from water reduces downtime, protects equipment, and improves performance.

Ready to Improve Your Fuel Operations?

Contact RedRiver LLC today to learn more about how does a fuel oil pressure vessel separator work and explore prefabricated, ASME-certified solutions tailored to your facility.

Frequently Asked Questions

1. What is a fuel oil pressure vessel separator?

A fuel oil pressure vessel separator is a device designed to remove water and contaminants from fuel oil under pressure. It ensures cleaner fuel reaches engines and equipment, protecting them from damage and improving efficiency.

2.Why are fuel oil pressure vessel separators used in industry?

They are used to protect critical machinery from water-induced corrosion and wear. By providing clean fuel, these separators improve engine performance, reduce maintenance costs, and help prevent unexpected downtime in industrial operations.

3. What types of fuel can a pressure vessel separator handle?

Diesel, kerosene, and other fuel oils are common. Designs vary by fuel type, and some models also handle gases like propane or helium.

4. How long can a separator last before needing replacement?

With proper maintenance, 10–20 years or more. Poor upkeep or corrosion can shorten its lifespan.

5. Is prefabrication really more cost-effective?

Yes. It cuts on-site labor, avoids delays, and ensures quality through controlled shop fabrication.

Key Takeaway

- A fuel oil pressure vessel separator relies on multi-stage separation to remove water and particulates.

- Gravity, coalescers, and carefully engineered chambers work together to boost fuel cleanliness.

- Maintenance tasks like draining water, checking gauges, and changing coalescer media are vital for efficiency.

- ASME-certified construction confirms the vessel’s ability to operate under specific pressures and safety standards.

- Prefabrication often speeds up installation and reduces on-site costs, especially when you need a high-performance setup.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author