How Does the Sheet Metal Fabrication Process Work

Understanding how does the sheet metal fabrication process work helps you see how metal sheets transform into durable structures. Red River LLC in Texas leads this process with precision, safety, and efficiency from design to installation.

Exploring How Does the Sheet Metal Fabrication Process Work

If you’ve ever asked yourself, “How does the sheet metal fabrication process work?” you’re in the right place. Imagine you’re piecing together a puzzle made of metal there’s design, cutting, shaping, and finishing involved at every step. Each piece serves a specific purpose, and when done correctly, it transforms a flat sheet of metal into a functional masterpiece. Whether you’re curious about the nuts and bolts or considering working with a fabrication partner, let’s explore this process so you can feel confident in every step you take.

How Does the Sheet Metal Fabrication Process Work

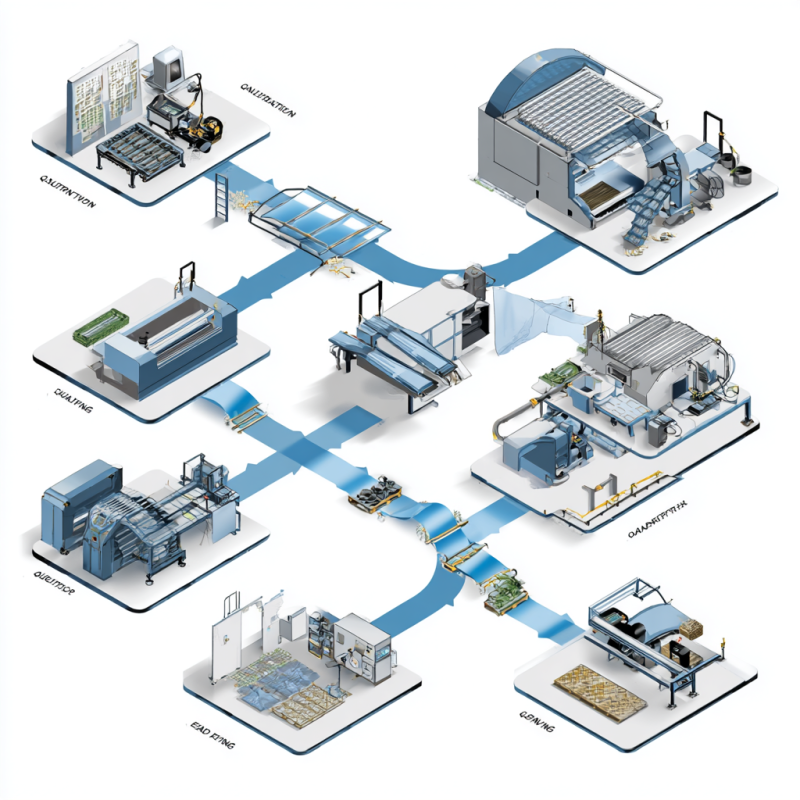

To set the stage, the sheet metal fabrication process generally starts with a conceptual design. From there, high-tech machinery (like laser cutters) and skilled fabricators transform raw metal sheets into tailored parts. One of the biggest advantages of sheet metal fabrication is its versatility; you’ll find it in anything from pressure vessels to modular skids to everyday appliances.

Professional companies such as Red River follow strict quality protocols and maintain controlled manufacturing environments to minimize errors. By doing so, they deliver highly precise results that bring cost savings and increased safety to the table.

Step 1: Identifying Needs and Design Planning

The first step in the stages of sheet metal fabrication is all about understanding the final product’s needs. You or your project’s engineer will gather essential details, such as:

- The function of the part or product

- Specific dimensions and tolerances

- Environmental conditions the product will face (e.g., high temperature, moisture)

Fabricators often rely on advanced CAD software to lay out the blueprint. If you’re contemplating a specialized build, explore custom sheet metal fabrication for an in-depth look.

Step 2: Material Selection

The next stage in the stages of sheet metal fabrication is picking the right metal. Each material aluminum, stainless steel, carbon steel brings something unique to the table:

- Aluminum: Lightweight, corrosion-resistant, popular in automotive and aerospace. For more details, see what is aluminum sheet metal fabrication.

- Stainless steel: Highly corrosion-resistant, excellent for food processing or medical settings. If that interests you, learn more at what is stainless steel sheet metal fabrication.

- Carbon steel: Very strong, relatively low cost, often used for structural applications.

A reputable provider will guide you through material selection.

Step 3: Cutting and Shaping

After design and material selection, the metal sheets are cut using CNC machines, laser cutters, or waterjet cutters.

Shaping or forming uses press brakes or rolling machines. For advanced precision, explore precision sheet metal fabrication.

Step 4: Welding and Joining

Welding joins the pieces using techniques like MIG, TIG, or stick welding. Safety is key, and Red River emphasizes a robust safety culture.

Step 5: Finishing Touches

Finishing may include grinding weld seams, galvanizing, painting, or powder coating. This step enhances both aesthetics and durability.

Step 6: Assembly and Final Check

Everything comes together in the assembly stage. Beyond fitting each piece, quality control teams inspect the work thoroughly. They check dimensions, look for imperfections, and run operational tests. Many companies rely on advanced scanning technologies and thorough documentation here. If you’re intrigued by how a provider might handle rigorous final checks, what are the steps in the sheet metal fabrication process offers a more detailed perspective on verifying each stage before shipping.

Step 7: Delivery or Installation

Finally, fabricated parts are shipped or installed. Prefabricated modules reduce on-site labor and downtime, a strategy used by Red River in modular skid packages.

Benefits of a Controlled Environment

Using a controlled manufacturing environment ensures:

- Weather delays and on-site interruptions are nearly eliminated

- Quality control improves because machines stay calibrated in stable conditions

- BIM (Building Information Modeling) reveals potential clashes before fabrication starts, minimizing mistakes

This leads to fewer surprises during installation, which saves you time and money. If you’re researching your options, it’s helpful to compare sheet metal fabrication services that offer comprehensive in-house solutions versus those relying on multiple subcontractors.

Prefabrication: An industry Game-Changer

Prefabrication means building entire modules or sections off-site, then shipping them assembled or nearly assembled. It’s especially powerful for large-scale energy or mining facilities that need a faster way to go from concept to production. Companies like Red River harness this approach to deliver consistent quality in their modular fabricated skid packages and packaged equipment.

Many industrial clients appreciate how prefabrication simplifies logistics. Instead of juggling multiple deliveries on-site, they receive a near-finished product. It’s a hassle-free method that can lower overhead costs. If you have big plans, see how to choose a sheet metal fabrication service provider for tips on picking a partner experienced in modular construction.

Practical Uses Across Industries

Sheet metal fabrication isn’t limited to one field. Industries like water treatment, renewable energy, and food processing rely on custom metal fabrication techniques, using custom metal fabrication techniques for unique solutions.

- Energy Sector: Pressure vessels that handle high heat or corrosive agents

- Agriculture: Grain storage solutions, silo attachments, or piping systems

- Automotive/Aerospace: Lightweight structural pieces or custom brackets

- Medical: Sterile cabinets, surgical trays, specialized equipment

For each specific industry, you can read more about how custom sheet metal fabrication and the metal cutting and forming process adapt to specialized operational requirements.

Factors that Influence Cost

When you’re planning a new fabrication project, budget is always on your mind, as factors like the metal cutting and forming process significantly shape the final quote:

- Material choice: Some metals cost more per pound than others.

- Complexity: More bends, welds, or intricate shapes translate to extra labor.

- Finishing requirements: Basic grinding is cheaper than advanced coatings or multiple finishing layers.

- Volume: Bulk orders may receive per-unit discounts.

- Lead times: Rush jobs can boost your costs if you need parts shipped ASAP.

If you want a clearer breakdown, how much do sheet metal fabrication services cost is a useful reference to help you plan effectively.

Why You Should Prioritize Quality Control

Quality control isn’t just a buzzword. A single mistake such as an incorrect weld or a poorly cut piece can snowball into safety risks, operational downtime, or product recalls. Reputable shops invest in thorough documentation, daily team huddles, and strict processes to ensure every product meets its specification. Not only does this keep you safe, but it also protects your wallet from costly rework.

In fact, companies like Red River track their materials from start to finish, ensuring full traceability and compliance. By applying rigorous checks, they deliver pressure vessels and fabrications that comply with ASME guidelines for the highest performance and reliability (Red River).

How Does the Sheet Metal Fabrication Process Work in Summary

So, how does the sheet metal fabrication process work from start to finish? It’s a detailed, multi-phase procedure that transforms raw metal into reliable components through design, cutting, welding, and finishing. By working with Red River LLC in Texas, you ensure your project benefits from precision, prefabrication and certified quality control.

Partner with Red River LLC Today

Ready to begin your next project? Red River LLC offers turnkey sheet metal fabrication, prefabrication, and modular assembly services. Get in touch today and experience excellence at every stage.

Frequently Asked Questions

1. What Is the Sheet Metal Fabrication Process?

The sheet metal fabrication process is the method of turning raw metal sheets into functional parts and components used in industries like automotive, construction, aerospace, and energy. It involves shaping, cutting, and assembling metals to precise specifications.

2. What Are the Steps in the Sheet Metal Fabrication Process?

The typical steps include: design and engineering, cutting, forming, joining (welding, riveting, or adhesive bonding), finishing (painting, polishing, or coating), and quality inspections. Each stage ensures that the final product meets specifications and standards.

3. How Does Custom Sheet Metal Fabrication Work for Complex Designs?

Designers use advanced software to plan, test fit, and ensure accurate cutting, forming, and assembly.

4. Does Prefabrication Help Reduce Timelines?

Yes, prefabricated modules installed on-site reduce weather delays, save labor, and significantly shorten project timelines.

5. What Is Precision Sheet Metal Fabrication?

Precision fabrication uses high-tech machinery and tight tolerances, ideal for producing extremely accurate sheet metal parts.

6. Is Aluminum or Stainless Steel Better for My Project?

Aluminum is lightweight and corrosion-resistant; stainless steel is stronger. Choose based on environment, budget, and design.

7. Can I Combine Multiple Metals in One Project?

You can, but experts advise considering corrosion differences and galvanic reactions when combining different metals.

8. How Can I Keep Fabrication Costs Down?

Provide clear designs, select materials wisely, and partner with experts to optimize cutting and forming.

Key Takeaways

- Begin every project with a thorough design phase and material planning.

- Prefabrication in a controlled environment can minimize errors and accelerate deadlines.

- Welding and finishing steps protect your product’s strength, appearance, and longevity.

- Quality control is crucial for cost management and overall safety.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author