Stainless Steel Sheet Metal Fabrication: What You Need to Know

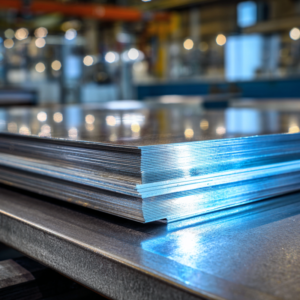

Stainless steel sheet metal fabrication offers durability, corrosion resistance, and aesthetic appeal for a wide range of applications. This guide breaks down how the process works, its benefits, and how to choose the right fabrication partner.

Understanding Stainless Steel Sheet Metal Fabrication

If you’re exploring stainless steel sheet metal fabrication for the first time, you might be pleasantly surprised by how versatile and dependable this process can be. Whether you’re designing industrial parts, kitchen equipment, or architectural elements, stainless steel often ranks as a top choice thanks to its rust resistance and sleek appearance. Below, you’ll discover how this fabrication method works and why Red River LLC is a trusted partner.

Understanding Stainless Steel Sheet Metal Fabrication

When we talk about stainless steel sheet metal fabrication, we’re describing the process of transforming flat sheets of stainless steel into a finished component or product. This can involve cutting, bending, welding, or finishing the metal to meet specific requirements. Stainless steel is highly valued for its ability to resist corrosion and maintain strength under varying temperatures, making it essential for everything from manufacturing equipment to consumer appliances.

If you want a quick explanation of the basics, you can check out our guide on what is stainless steel sheet metal fabrication. That overview touches on exactly how stainless steel differs from other metals, plus it highlights common fabrication steps.

Why stainless steel?

Before you consider other metals, it’s good to ask: what makes stainless steel special? For starters, stainless steel sheet metal fabrication delivers exceptional corrosion resistance and long-term durability, making it ideal for demanding environments. Unlike other materials, stainless steel sheet metal fabrication provides a clean, modern look while maintaining strength under pressure. Because of its versatility across industries, stainless steel sheet metal fabrication remains a top choice for producing reliable, high-quality components.

- Corrosion Resistance: With proper chromium content, stainless steel withstands humid and harsh environments far better than plain carbon steel (learn more).

- Visual Appeal: Its polished surface creates a modern look, perfect for exposed structures (see our projects).

- Strength-to-weight ratio: Robust yet workable, stainless steel delivers durability without excessive heft (more on material selection).

Industries using stainless steel enjoy longer product lifespans, fewer replacements, and reduced long-term costs. Even in high-wear settings, stainless steel components remain functional longer than many alternatives (explore our capabilities).

The Benefits of Stainless Steel for Sheet Metal Fabrication

Stainless steel doesn’t just stand out for its resilience. It brings additional perks when you’re specifically working with stainless steel sheet metal fabrication, offering superior strength and corrosion resistance for long-lasting results. Through stainless steel sheet metal fabrication, manufacturers achieve precise, clean finishes that elevate both function and appearance. This makes stainless steel sheet metal fabrication a preferred method for industries that demand reliability. Ultimately, stainless steel sheet metal fabrication ensures durable, high-quality products that consistently perform under pressure.

Versatility of Grades

There’s no single version of stainless steel, and understanding these variations is essential when planning stainless steel sheet metal fabrication. Grades like 304 or 316 each bring unique benefits that influence the results of your stainless steel sheet metal fabrication, with 304 ideal for general applications and 316 offering superior chloride resistance. Choosing the right grade ensures your stainless steel sheet metal fabrication remains cost-effective without sacrificing performance. With the proper material selection, stainless steel sheet metal fabrication delivers the strength and durability your application requires.

Cleanliness and Hygiene

Because stainless steel is easy to sanitize, you often see it in food service counters, medical equipment, or pharmaceutical machinery. If your project demands rigorous cleanliness standards, stainless steel fabrication might be your best bet.

Aesthetic Appeal

Many designers choose stainless steel for its refined, professional appearance that effortlessly elevates any space. From gleaming fixtures in a building lobby to seamless countertops in a busy commercial kitchen, the material’s visual appeal enhances both style and function. When used in stainless steel sheet metal fabrication, it offers a sleek, modern finish that stands the test of time. This is why professionals often rely on stainless steel sheet metal fabrication to achieve high-end results for their projects done efficiently.

Cost Efficiency Over Time

While stainless steel can be pricier than mild steel on a per-sheet basis, stainless steel sheet metal fabrication often pays off through long-term durability. With fewer repairs and less corrosion-related damage, stainless steel sheet metal fabrication reduces the need for replacements or frequent fixes. Over a product’s lifespan, the stable performance and minimized downtime delivered by stainless steel sheet metal fabrication typically outweigh the initial investment.

The Stainless Steel Sheet Metal Fabrication Process

Curious about what happens behind the scenes? While every facility has its specific methods, most fabrication workflows share a few common steps.

1. Cutting the Metal

Fabricators begin by cutting large sheets of stainless steel into workable pieces. Traditional methods like shearing are common, but many modern shops now use laser cutting or water-jet cutting to achieve cleaner edges with greater precision. If you’d like a broader look at these processes, consider exploring our overview of the sheet metal fabrication process.

laser cutting relies on intense beams of light to slice smoothly through the metal, maintaining high accuracy. water-jet cutting, on the other hand, uses a pressurized water stream (often combined with an abrasive) to handle thicker or denser stainless steel grades.

2. Forming the Sheets

Next, the cut metal is bent into shapes or contours using common forming techniques such as press braking or rolling, transforming flat sheets into precise, three-dimensional components ready for assembly or further fabrication processes.

- Press braking: A high-pressure machine clamps a sheet between a punch and die to form consistent bends.

- Rolling: Metal sheets pass through rollers to achieve cylindrical or curved shapes.

Forming transforms flat metal sheets into three-dimensional components, turning simple pieces into functional parts. Accuracy during this stage is critical, as precise measurements ensure proper bend angles. Any deviation can result in misaligned or poorly fitting components, potentially compromising the assembly and overall quality of the finished product.

3. Joining and Assembly

Once formed, parts often need to be joined. welding is the go-to for stainless steel, typically using TIG (tungsten inert gas) or MIG (metal inert gas) methods. Skilled welders ensure joints are strong, smooth, and free of defects like cracks.

If you’re creating more complex assemblies, you may need to incorporate fasteners, adhesives, or rivets to ensure everything stays securely connected. The goal is to join all components without compromising the clean, professional appearance or the material’s natural corrosion resistance, allowing the finished product to remain strong, seamless, and long-lasting in demanding environments.

4. Finishing Touches

After welding, you’ll want to polish or passivate the metal so it’s both smooth and corrosion-resistant. Passivation, for instance, is a chemical treatment that removes free iron from the surface, helping the stainless steel maintain its protective chromium oxide layer. Polishing or buffing can deliver a mirror-like finish or a more subdued brushed appearance.

For projects needing heavy-duty protection, extra coatings or sealants can be applied, although this is less common with stainless steel than carbon steel. Once fabrication is complete, every component undergoes thorough inspection to ensure it meets precise dimensional measurements and quality standards, guaranteeing durability, reliability, and consistent performance for the finished product in its intended application.

Choosing a Partner for Stainless Steel Sheet Metal Fabrication

Selecting the right fabrication shop is essential for project success. Here are some pointers on how to narrow your search:

- Check certifications and experience: Look for a proven track record in stainless steel fabrication (about Red River LLC).

- Assess capabilities: Not all shops can handle the same scope. If you have a large design in mind, you’ll want a facility with robust cutting and forming machinery, as well as skilled welders. For more insights, take a peek at how to choose a sheet metal fabrication service provider.

- Request sample work or references: Review prior projects to gauge quality (portfolio and blog).

- Evaluate communication: Ensure clear, consistent updates throughout production (contact us).

- Compare costs carefully: Balance value with quality to avoid cutting corners (request a quote).

If you’re also considering other metals, you could look into aluminum sheet metal fabrication or precision sheet metal fabrication. Comparing different materials is a smart way to confirm you’re making the best choice for your application.

Prefabrication and Modular Approaches

Some advanced manufacturers integrate prefabrication or modular construction into their process, especially in complex builds. Prefabrication happens in a controlled environment, reducing environmental hazards, saving time, and helping teams identify design conflicts early. Companies like Red River LLC showcase how modular fabrication can streamline everything from shipping to inspection.

Even if your project is relatively small, a fabricator experienced in modular methods can often deliver higher consistency, less on-site labor, and smoother installation. With stainless steel, you can combine prefabricated components for a faster, more reliable production cycle.

Stainless Steel Sheet Metal Fabrication for Long-Term Success

Stainless steel sheet metal fabrication provides a reliable and versatile solution for your production needs. Its natural corrosion resistance, durability, and stylish finish make it an ideal pick for countless applications in manufacturing, construction, and hospitality and beyond. As you map out your next project, keep in mind that selecting the right fabricator is as important as picking the right material. A seasoned expert can help you pinpoint the best stainless steel grade, recommend cutting-edge forming techniques, and ensure your finished product lives up to its goals.

If you’d like more details on custom solutions, you can also explore custom sheet metal fabrication. Each project is unique, so it’s always wise to find a specialist who’s ready to understand your vision and produce a precise, cost-effective result.

Partner with Red River LLC for Stainless Steel Sheet Metal Fabrication

Looking for a dependable provider? Red River LLC delivers high-quality stainless steel sheet metal fabrication backed by expert craftsmanship, advanced equipment, and reliable turnaround times. Whether you need prototypes or large-scale production, our team ensures every detail meets your specifications (contact us).

Frequently Asked Questions:

1. What is stainless steel sheet metal fabrication?

Stainless steel sheet metal fabrication is the process of cutting, bending, and assembling stainless steel sheets to create custom parts, components, or structures.

2. How does stainless steel sheet metal fabrication work?

Stainless steel sheet metal fabrication works by using specialized equipment and techniques to cut, form, weld, and finish stainless steel sheets into precise, functional designs.

3. Why use stainless steel sheet metal fabrication?

You use stainless steel sheet metal fabrication because it offers excellent durability, corrosion resistance, strength, and versatility for a wide range of industrial and commercial applications.

4. Does stainless steel fabrication require special welding?

Yes, welding stainless steel calls for more precision to prevent warping and maintain corrosion resistance. TIG and MIG welding are common approaches.

5. How do I know if I need a custom solution?

If standard off-the-shelf items can’t match your dimensions, shapes, or performance needs, custom fabrication is the way to go. This might include unique assemblies or specific design features. Our resource on why use custom sheet metal fabrication covers more details.

6. What’s the typical lead time for a stainless steel fabrication project?

It depends on the project’s size, complexity, and the shop’s workload. Straightforward parts might take days, while complex assemblies or large orders can run into several weeks.

7. Can stainless steel be combined with other metals in fabrication?

It’s possible, but you’ll want to be sure the metals are compatible. Dissimilar metals can corrode faster when placed in direct contact, especially in corrosive environments. Skilled fabricators can advise on proper isolation methods.

8. Is there a minimum order size?

Every fabricator has its own policies. Some handle quick, one-off tasks, but others may only accept larger orders. It’s always best to ask about minimums when you first contact them.

Key Takeaways

- Stainless steel’s corrosion resistance makes it valuable in high-wear or high-moisture environments.

- Different grades of stainless steel allow you to fine-tune cost and performance.

- Fabrication processes typically include cutting, forming, welding, and finishing.

- Selecting the right partner means checking certifications, capabilities, and communication style.

- Over the product’s life cycle, stainless steel often saves money by minimizing repairs and replacements.

Related Blog Post

Water Filter Replacement

Why Use Stainless Steel Sheet Metal Fabrication?

How Does Stainless Steel Sheet Metal Fabrication Work

What Is Stainless Steel Sheet Metal Fabrication?