Mechanical failure analysis identifies root causes of breakdowns like material flaws, design errors, or corrosion to prevent costly downtime and improve reliability. For industries using pressure vessels, combining this process with prefabrication enhances safety, strengthens durability, and supports long-term efficiency.

Understanding What Is Mechanical Failure Analysis in Industry

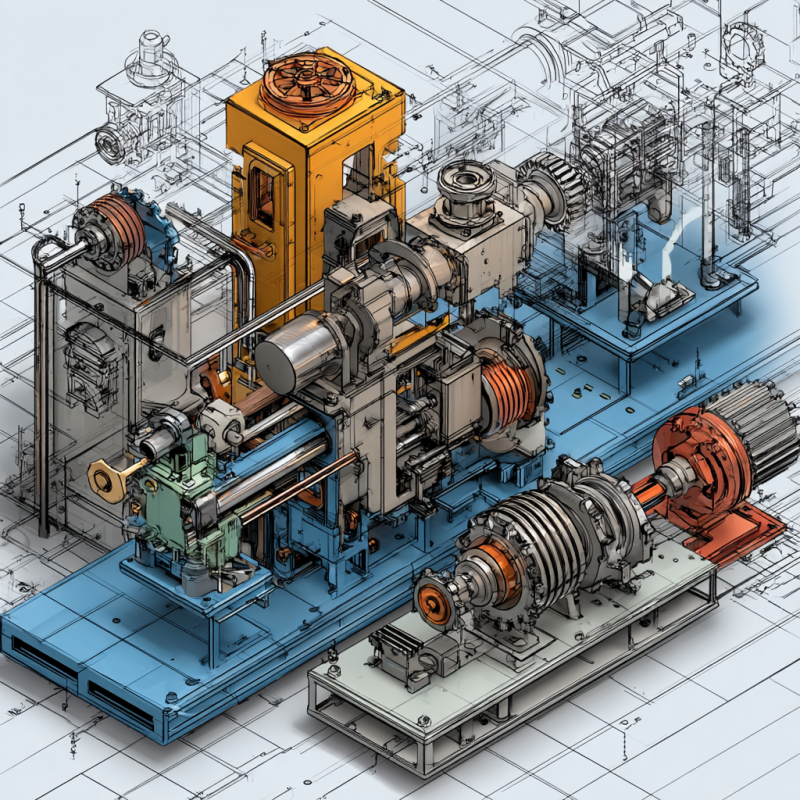

What is mechanical failure analysis? Mechanical failures can strike anywhere—pumps, pipelines, or full industrial plants causing costly downtime and unexpected breakdowns. The structured process of mechanical failure analysis goes beyond identifying a part that “broke.” It digs into root causes like material flaws, overloading, or harsh environmental conditions. For industries using pressure vessels, this approach is vital to prevent cracks, leaks, and safety risks. Combined with prefabrication, which ensures quality through controlled manufacturing, facilities gain stronger reliability, reduced risks, and solutions that keep systems running smoothly.

Understand What is Mechanical Failure Analysis

Mechanical failure analysis, at its simplest, is an in-depth investigative process that uncovers why a mechanical part or system did not perform as expected. This approach goes beyond simply saying a part “broke” or “weakened.” Instead, it explores the root causes, such as:

- Material flaws: Hidden imperfections in metals or welds.

- Overloading beyond design limits: Excessive force or pressure.

- Environmental conditions: Corrosion, extreme temperatures, or vibration.

- Manufacturing defects: Poor welding technique or incorrect assembly.

The ultimate goal is to diagnose what went wrong so you can map out a permanent fix. In the pressure vessel industry, for instance, a thorough mechanical failure analysis clarifies whether a factory-made seam was stressed to its limit or if a certain corrosive fluid triggered premature deterioration. Studying the specifics helps you prevent the same problem from arising again.

According to Red River LLC, a trusted ASME pressure vessel provider, mechanical failure analysis reveals hidden issues in design, materials, and environmental factors. This process saves time, reduces costly breakdowns, and strengthens reliability. It also supports your risk management plan by documenting causes of failure, ensuring better prevention strategies, and helping avoid repeat problems in the future.

If you ever want to explore a deeper look at how this process applies to different systems, you could compare it with related topics like pressure vessel failure analysis or structural failure analys is. Each type zeroes in on specific stresses and usage, but they all share the same underlying logic: find what caused the failure, then fix it before it recurs.

Key Causes and Contributing Factors

Many mechanical components operate under enormous stress, especially in demanding industries like power generation, mining, agriculture, and oil refining. Over time, the everyday loads can build up, introducing micro-cracks and other flaws that you rarely see on the surface. Here are some common causes and factors:

- Material selection problems: Using the wrong metal or cheaper alloy often causes cracks, wear, and premature failure.

- Incorrect design assumptions: Design errors occur when real-world conditions exceed expectations, causing failures.

- Environmental effects: Moisture, chemicals, saltwater, and dust exposure rapidly accelerate component corrosion.

- Manufacturing flaws: Weld defects or poor machining create stress points that become cracks.

- Maintenance gaps: Skipping inspections or ignoring small cracks quickly turns into major failures.

Knowing these causes arms you with preventative strategies. You can plan regular inspections, choose better materials or coatings, adjust your operational parameters, and have robust quality controls in place. If you are curious about exploring the science behind each factor, feel free to read more at mechanical failure analysis, where you will find deeper discussions on root causes and testing methods.

Benefit for Pressure Vessels

If you work with pressure vessels, tanks, reactors, or other enclosed containers under pressure, you already recognize how critical reliability is. A single weld fault or material flaw can trigger cracks that compromise the vessel’s integrity. Because pressure vessels store liquids or gases at high pressure, even a small leak can be dangerous and very costly.

This is where mechanical failure analysis becomes your guide. By studying the manufacturing process, the stress distribution, and the types of fluids involved, you can:

- Identify weaknesses: Does a section of the vessel wall show thinning due to corrosion? Are there signs of micro-cracks along weld seams?

- Pinpoint the correct repair: Should you replace the entire zone or overlay the weld? Which material grade can withstand the stress better?

- Improve future designs: If you see repeated failures in one region, perhaps the vessel’s geometry needs reinforcement, or operators must reduce load spikes.

According to Red River LLC, strong quality control extends vessel lifespan, while applying advanced coatings or adjusting inspection schedules improves safety and reliability.

It also helps to connect the dots with additional resources, especially if you are exploring deeper questions like what causes pressure vessel failure or the differences between mechanical and metallurgical failure analysis. Gathering varied perspectives paints a more complete picture of your vessel’s health and life cycle.

Role of Prefabrication

Prefabrication, building components in a controlled facility before shipping them to the final site, offers another protective layer for your systems. Rather than on-site fabrication (exposed to weather, dust, or limited quality checks), prefabricated parts undergo strict inspection, standardized assembly, and rigorous testing in an ideal environment.

Red River LLC, for example, has moved from manual isometric drawings to advanced 3D modeling and prefabrication. This controlled approach cuts down on:

- Unwanted welding errors due to weather and rushed on-site conditions

- Variations in assembly quality

- Extra shipping time for small fixes

Prefabrication identifies conflicts early, reducing accidents, insurance costs, and failures. It integrates mechanical failure analysis, ensuring vessels and modules are built with fewer weaknesses and stronger long-term reliability.

If you decide to dig deeper into analyzing how components fail under different conditions, you might also consider specialized angles like corrosion failure analysis or fatigue failure analysis. These subsets look at corrosion impacts and cyclic loading, two frequent culprits in industrial settings.

Mastering What Is Mechanical Failure Analysis

When you break down repeated mechanical breakdowns, you often discover that a small miscalculation or tiny crack spun out of control. Mechanical failure analysis is your roadmap to stop that snowball effect. By looking at the root causes, material flaws, defective designs, or environmental stressors, you build a plan that keeps problems from returning.

Think of this approach as a long-term investment in your equipment and your bottom line. You will spend fewer resources on emergency repairs and run a smoother, safer operation. Meanwhile, prefabrication methods act as an insurance policy, reinforcing each component before it ever sees real-world stress. You gain confidence that your pressure vessels, pipelines, or mechanical assemblies can handle the load.

If you are weighing whether to implement a detailed failure analysis, remember that each step you take toward deeper investigation pays off in more consistent performance. You reduce the risk of on-site hazards, keep your costs down, and preserve valuable reputation points in your industry.

Take Action with Red River LLC Today

Ready to strengthen your systems? Contact Red River LLC today to explore expert solutions in mechanical failure analysis and pressure vessel manufacturing. Build a safer, stronger future for your operations.

Frequently Asked Questions

1. How to perform mechanical failure analysis?

To perform mechanical failure analysis, experts examine failed parts, study operating conditions, and use testing methods to determine the cause.

2. Why is mechanical failure analysis important?

Mechanical failure analysis is important because it prevents future breakdowns, improves safety, and reduces costly downtime.

3. Can mechanical failure analysis help extend pressure vessel life?

Early crack or corrosion detection lets you adjust maintenance, preventing failures and extending lifespan.

4. Is prefabrication really worth the effort?

Prefabrication ensures consistent quality, reduces costly on-site errors, accelerates timelines, and improves reliability.

5. Should I only do analysis after a failure happens?

Earlier is better; proactive inspections detect early damage, enabling repairs before major failure.

6. What if the problem is ongoing or repeats often?

If problems recur, use specialized analysis: investigate, find material flaws, confirm design suitability.

7. Does mechanical failure analysis apply to non-metal parts?

Metals, polymers, ceramics, and composites fail; mechanical failure analysis examines stress and environmental reactions.

Key Takeaway

- Thorough investigations of breakdowns help you tackle the exact root cause.

- Environmental conditions and design assumptions are just as important as materials.

- Prefabrication streamlines production and reduces hidden weaknesses.

- Pressure vessels gain a major safety edge when analyzed and built with strict standards.

- Identifying failures early safeguards budgets, timelines, and workforce safety.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author