What Is Stainless Steel Sheet Metal Fabrication?

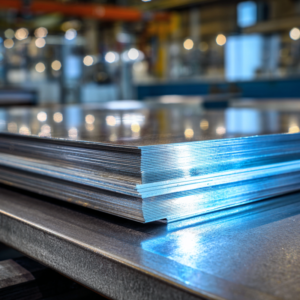

Stainless steel sheet metal fabrication is the process of cutting, bending, and assembling stainless steel sheets to create durable components for construction, automotive, industrial, and consumer applications. It is preferred for its corrosion resistance, longevity, and clean finish.

Understanding What Is Stainless Steel Sheet Metal Fabrication

Stainless steel sheet metal fabrication might sound a bit technical at first, but understanding what is stainless steel sheet metal fabrication makes it surprisingly straightforward. You see stainless steel all around you think of kitchen appliances , industrial equipment, When you hear the term “fabrication,” it refers to the entire process of shaping, cutting, welding, and assembling these sheets into a finished product ready to serve specific needs. Whether you are looking for more durable household items or specialized industrial parts, knowing what is stainless steel sheet metal fabrication can help you see why stainless steel is so popular.

In this article, you will learn how stainless steel sheet metal transforms from flat panels into functional pieces, as well as how prefabrication, pressure vessels, and modular solutions come into play. By the end, you will know exactly how this fabrication technique can make projects more efficient, reduce costly errors, and deliver high-quality results for any application.

Explore What is Stainless Steel Sheet Metal Fabrication

Let’s start with a simple explanation. When you ask, “what is stainless steel sheet metal fabrication,” you are essentially asking how skilled professionals take inert sheets of stainless steel and convert them into a diverse range of products. This could involve anything from a small bracket to a huge structural component inside a manufacturing plant. These sheets are typically made of chromium-containing steel, which gives stainless steel its unique rust-resistant properties.

Definition and Background

- “Sheet metal” is a flat metal stock available in various thicknesses (often called “gauges”).

- “Fabrication” covers several steps like cutting, bending, welding, polishing, and final assembly.

- Stainless steel’s resilience against corrosion makes it a top choice in industries that need cleanliness and durability (food processing, healthcare, energy, and more).

Why Stainless Steel?

Its strength-to-weight ratio and corrosion resistance make the stainless steel fabrication process essential in industry; understanding the stainless steel fabrication process is key (learn more about material selection).

Common uses today

Stainless steel sheet metal finds its way into:

- Medical tools that require antimicrobial surfaces.

- Architectural features like decorative panels and handrails.

- Infrastructure and construction projects needing strong load-bearing components.

- Pressure vessels designed for industries like water treatment and oil and gas (Red River LLC).

Understand the fabrication process

Building a modular skid requires industrial sheet metal fabrication, and mastering industrial sheet metal fabrication ensures precision, strength, and efficiency in every project.

Cutting and Shaping

- Laser cutting, water jet cutting, or plasma cutting might be used, depending on the thickness and the required precision.

- For shaping stainless steel, presses or rolling machines come into play to create arcs and bends.

- The goal is to achieve the exact dimensions needed before any assembly begins.

Forming and Assembling

Once each piece is shaped, you join them together. Traditional welding is common, but sometimes fasteners or adhesives are used. In the case of industrial projects, you might see advanced welding techniques that ensure full material penetration for high-pressure applications (see welding positions)

Finishing Touches

After the initial shape is set, fabrication teams will smooth edges, remove any sharp burrs, and perform surface treatments. Finishes range from a basic matte look to a mirrored polish. This finishing enhances corrosion resistance, cleanliness, and aesthetics (read about metal finishing).

If you are curious about the broader scope of how transforming metal sheets works, you could explore the metal sheet fabrication process to see all the ways metal is morphed into final products.

See Why Prefabrication Matters

Prefabrication is a game-changer in stainless steel sheet metal fabrication. Instead of transporting raw materials to a work site and building everything in a haphazard environment, professionals assemble modules or skids in a controlled facility. This approach is especially handy for large-scale industrial projects where on-site labor, time, and risk can be huge cost factors.

Cost savings and efficiency

Working in a well-equipped shop means less downtime caused by weather disruptions or logistics delays. Every piece is created in a predictable schedule, so you do not need to worry about last-minute site changes that inflate budgets.

- Prefabrication significantly reduces shipping costs since modules are assembled in sections.

- Labor hours are consolidated, which often leads to fewer mistakes and less rework.

- Efficiency climbs because skilled teams can work together under one roof, sharing resources and expertise.

Quality Assurance

Because everything happens in a single location, you get a uniform standard of quality. Skilled welders, inspectors, and quality control staff can test each piece for strength, durability, and compliance (ASME-certified vessels).

Reduced on-site Risk

Fewer people working on your property means fewer accidents. Prefabricating stainless steel components prevents random on-site issues, from weather-related hazards to space constraints and workforce fluctuations. By the time these modules or parts arrive on location, they are essentially plug-and-play (contact Red River LLC).

Discover the Role of ASME Pressure Vessels

A major branch of stainless steel sheet metal fabrication is the creation of pressure vessels. These specialized containers hold gases or liquids at pressures different from the outside atmosphere (learn about pressure vessels).

Regulatory Standards

Regulations like the ASME Boiler and Pressure Vessel Code outline what materials you can use, the required thickness, safe working pressures, and quality checks.

Tailoring Pressure Vessels

In many cases, you might need a custom design to handle unique fluids or specialized processes. Stainless steel is a popular material because it can withstand corrosive elements and temperature fluctuations (custom solutions).

Manufacturing and Testing

Experienced welders use high-precision techniques to assemble each part under strict supervision. Tests like radiographic and ultrasonic inspections ensure there are no hidden flaws (pressure vessel inspection guide).

Choose a Reliable Fabrication Partner

Red River LLC excels in sheet metal manufacturing techniques, using advanced sheet metal manufacturing techniques for quality and precision.

Look for Certified Expertise

Ask if your chosen fabricator holds certifications (NBBI R Stamp, AWS membership, ASME U4 & R stamps). These stamps show they meet recognized quality and safety guidelines. If a fabricator invests in these credentials, it signals a real commitment to delivering the best results possible.

Check for custom solutions

Some manufacturers specialize in off-the-shelf components. Others offer fully custom or OEM solutions. If you have a specialized project, make sure your fabricator can adapt to your needs. The best partners will walk you through the entire process, from drafting a design to final on-site installation.

What Is Stainless Steel Sheet Metal Fabrication: Final Thoughts

Understanding what is stainless steel sheet metal fabrication helps engineers, contractors, and business owners make informed material decisions based on performance, aesthetics, and cost-efficiency (about Red River LLC).

What Is Stainless Steel Sheet Metal Fabrication for Reliable Solutions

Looking for precision, strength, and longevity? Red River LLC delivers expert support in what is stainless steel sheet metal fabrication for all project sizes. Contact us today to get a custom quote.

Frequently Asked Questions

1. How does stainless steel sheet metal fabrication work?

Stainless steel sheet metal fabrication works by using specialized equipment and techniques to cut, form, weld, and finish stainless steel sheets into precise, functional designs.

2. Why use stainless steel sheet metal fabrication?

You use stainless steel sheet metal fabrication because it offers excellent durability, corrosion resistance, strength, and versatility for a wide range of industrial and commercial applications.

3. Does stainless steel sheet metal fabrication cost more than aluminum fabrication?

Stainless steel costs more but offers longer-lasting, durable savings.

4. How does prefabrication help my project timeline?

Prefabrication consolidates work, speeding assembly, testing, and inspections efficiently.

5. Are all pressure vessels made from stainless steel?

Material choice depends on application, including stainless steel or alloys.

6. Can I get custom sizes and shapes with stainless steel?

You can explore the sheet metal fabrication services for customization.

7. Is stainless steel recyclable?

Stainless steel is recyclable, retaining strength and corrosion resistance.

8. How does quality control play a role in fabrication?

Stainless steel sheet metal fabrication uses inspections, stress tests, radiography, ensuring compliance.

Key Takeaways

- Stainless steel sheet metal fabrication involves cutting, shaping, welding, and finishing to create everything from small brackets to large industrial modules.

- Prefabrication streamlines the process, reducing on-site labor costs, minimizing errors, and speeding up project timelines.

- ASME-certified pressure vessels are essential in industries that handle pressurized liquids and gases, and stainless steel is a top choice for corrosion resistance.

- Choosing stainless steel often pays off in longevity, durability, and lower maintenance, making it a smart long-term investment.

Related Blog Post

Water Filter Replacement

Why Use Stainless Steel Sheet Metal Fabrication?

How Does Stainless Steel Sheet Metal Fabrication Work

Stainless Steel Sheet Metal Fabrication: What You Need to Know