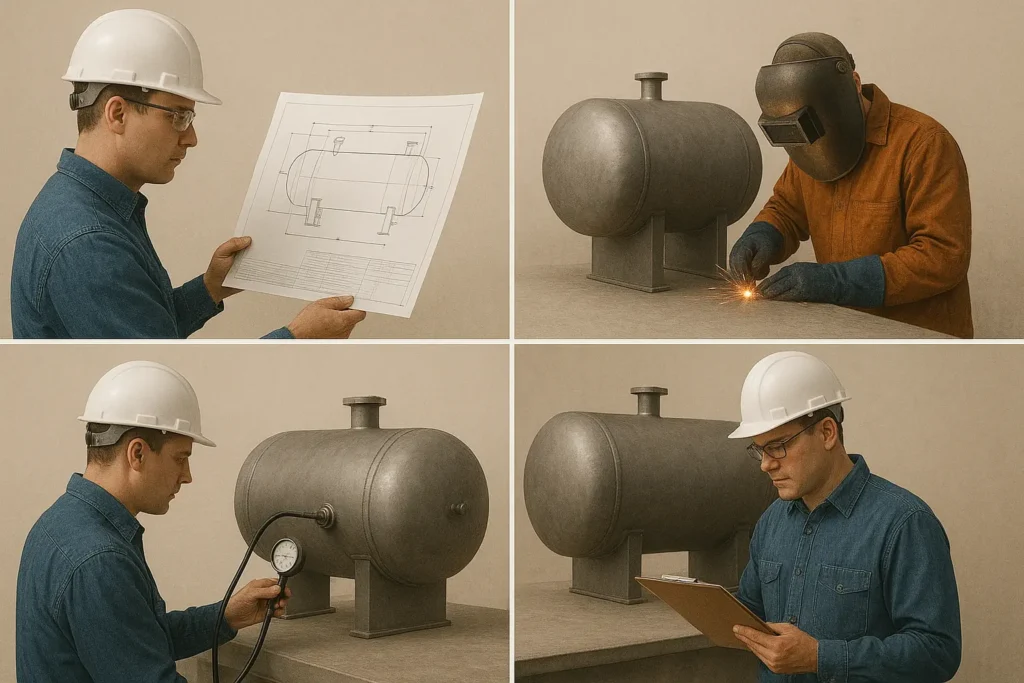

This blog explains Pressure Vessel Design and Engineering from requirements capture to materials, thickness calculations, welding, inspection, and documentation. You’ll learn how Pressure Vessel Design and Engineering integrates process data with shop realities to deliver safe, code-compliant results.

Understanding Pressure Vessel Design and Engineering

Pressure Vessel Design and Engineering is the structured conversion of real process conditions into a safe, traceable, testable pressure boundary that meets code and customer requirements. Red River LLC brings together mechanical design, materials science, welding and heat treatment practices, inspection methods, and digital documentation. In practical terms, Pressure Vessel Design and Engineering turns a process data sheet into calculations, drawings, welding procedures, inspection plans, and a complete Material Data Report (MDR) that stands up to audits.

Why Pressure Vessel Design and Engineering matters

Rigorous engineering prevents rework, delays, and integrity risks. By clarifying loads, temperatures, corrosion rates, transients, and interfaces early, ambiguity is removed before steel is cut. A skilled team uses careful planning to defuse conflicts between specifications, simplify fabrication, and reduce lifetime costs through smarter details, ensuring reliable performance and long-term efficiency in complex industrial projects. Learn more about safety and compliance in pressure vessel design.

Code Basis And Compliance In Pressure Vessel Design and Engineering

The process begins by selecting the governing code and mapping each clause to deliverables. Whether following a design-by-rules or design-by-analysis approach, engineering ensures joint categories, weld efficiencies, MDMT checks, PWHT rules, and NDE criteria are met. A compliance matrix maintained throughout the project serves as a central reference, helping the team track requirements, demonstrate adherence, and deliver vessels that meet safety, quality, and regulatory standards.

Documentation flow that auditors trust

The hallmark of rigorous engineering is a clean, revision-controlled data trail. This includes calculations, GAs, detailed fabrication drawings, weld maps, MTRs, WPS/PQR/WPQ, NDE reports, heat treatment charts, hydro or pneumatic test records, nameplate details, and the MDR. Maintaining a single source of truth makes inspections, audits, and project tracking straightforward and reliable. See our manufacturing process of pressure vessels for a deeper dive.

Materials, Corrosion, And MDMT In Pressure Vessel Design and Engineering

Material selection is a strategic decision. The team evaluates carbon steel, low alloy steel, stainless, duplex, and nickel alloys against corrosion, temperature, and mechanical demands. In sour or hydrogen service, hardness controls, PWHT requirements, and material toughness are specified to prevent cracking. For low-temperature applications, MDMT is calculated and impact testing is required where necessary. High-temperature designs consider time-dependent properties and allowable stresses. Choosing the right material for pressure vessel fabrication ensures safety, reliability, and long-term performance under diverse operational conditions.

Corrosion allowance, overlays, and linings

Engineering often begins with a sensible corrosion allowance. For aggressive media, solutions may include stainless overlays, strip cladding, or nonmetallic linings. Material and design selection reflect long-term inspection access and repairability, ensuring durability and maintainability. By addressing these factors early, the team minimizes future risks, simplifies maintenance, and extends the service life of the equipment while maintaining safety and efficiency.

Load Cases, Stress Categories, And Failure Modes In Pressure Vessel Design and Engineering

The defined load set includes internal pressure, external pressure or vacuum, deadweight, wind, seismic, nozzle loads, thermal gradients, transport, lifting, and test loads. Stresses are classified as primary membrane, primary bending, and secondary, then checked against limits. For complex geometry, formulas are supplemented with FEA and stress analysis, ensuring accurate assessment, compliance, and reliable vessel performance under all anticipated operating conditions. Learn more about types of failure in pressure vessels.

Typical failure modes to avoid

Plastic collapse, buckling under external pressure, ratcheting, fatigue at nozzles and attachments, brittle fracture at low temperature, and creep rupture are carefully managed. Well-designed details reduce stress concentrations, while engineering ensures supports, skirts, and saddles do not introduce unintended hotspots, improving safety, reliability, and the long-term performance of the equipment.

Thickness, Head Selection, And Nozzle Reinforcement In Pressure Vessel Design and Engineering

Converting loads into thickness is a core engineering activity. The choice among hemispherical, 2:1 ellipsoidal, or torispherical heads affects weight, cost, and forming feasibility. Nozzle reinforcement combines shell contribution, pad area, and interaction checks, while calculations, drawings, and weld maps are coordinated to ensure accuracy and reliable vessel performance.

Flanges, gaskets, and tightness

Seating stress and relaxation behavior are critical. Flange classes and gasket types are selected to maintain tightness across temperature cycles. Proper bolt load targets and torque procedures are incorporated into the testing plan, ensuring reliable sealing, consistent performance, and long-term safety under operational conditions.

Thermal Transients And Differential Expansion In Pressure Vessel Design and Engineering

Temperature is more than a number. Engineering models startup, shutdown, cleaning cycles, and quench scenarios to control gradients. Supports are checked for differential growth to prevent restraint-induced secondary stresses. Slots, expansion joints, and insulation details are employed to manage thermal effects, reduce risk, and ensure long-term reliability and safe operation.

MDMT, impact testing, and PWHT

The load set includes internal and external pressure, deadweight, wind, seismic, nozzle, thermal, transport, lifting, and test loads. Stresses are classified, checked against limits, and for complex geometry, FEA supplements formulas to ensure compliance, accuracy, and reliable vessel performance.

Welding, Heat Treatment, And NDE In Pressure Vessel Design and Engineering

Joints fail where details are weak. Engineering defines joint types and efficiencies, selects welding processes, and qualifies procedures and personnel. Essential variables in WPS/PQR/WPQ must align with P-Numbers and F-Numbers, and PQR evidence of soundness is recorded. Preheat and interpass controls limit HAZ hardness, while post-weld heat treatment ensures strength and integrity. Learn about 5G, 4G, and 3G welding positions for practical fabrication.

Inspection that finds what matters

NDE is targeted, not generic. Engineering specifies UT or RT for volumetric checks, MT or PT for surface cracks, and PMI for alloy verification. Acceptance standards are based on service severity, and reports are linked to weld maps and heat numbers, ensuring traceability, accuracy, and reliable verification of materials and weld integrity.

Dimensional Control And Fabrication Reality In Pressure Vessel Design and Engineering

Shops build according to drawings. Engineering sets tolerances for rolling, out-of-roundness, head fit, nozzle projection, and after-forming thickness. Hold points catch nonconformances early, and as-built data is maintained in sync with the traceable document set. See metal fabrications and prefabrication capabilities at Red River LLC.

Hydrostatic, Pneumatic, And Leak Tests In Pressure Vessel Design and Engineering

Testing proves integrity. Engineering defines hydrostatic test pressure, temperature control, venting, and safety boundaries. Pneumatic tests are used only when liquids are impractical, with strict controls and exclusion zones enforced. For critical tightness, helium leak tests may be specified, followed by verification of flange seating stresses and bolting procedures, ensuring safe, reliable performance and long-term operational integrity.

Supports, Skirts, Saddles, And Foundations In Pressure Vessel Design and Engineering

Loads must flow cleanly into the foundation. Engineering sizes skirts to resist overturning and checks skirt-to-shell transitions. Anchor bolts and base rings are coordinated with grout and pedestal geometry. For horizontal vessels, saddles are positioned to limit bending and local shell compression is verified. Wear pads and thicker courses are added where needed, ensuring structural integrity, stability, and long-term durability under operational loads.

Piping Interfaces And External Loads In Pressure Vessel Design and Engineering

Nozzle loads rarely appear unexpectedly. Engineering obtains load data from piping stress analysis and incorporates them into reinforcement and local stress checks. When loads are high, adjustments to piping routing or added flexibility are coordinated. Early collaboration ensures mature planning, reduces stress-related risks, and integrates design and operational considerations for safer, more reliable vessel performance.

Fatigue And Cyclic Duty In Pressure Vessel Design and Engineering

Cyclic service drives component life. Engineering evaluates fatigue using accepted methods, focusing on weld toes, ligaments, and attachments. Smoother transitions and blended weld toes reduce stress concentrations. Inspection plans are tailored to actual hot spots rather than fixed intervals, ensuring targeted monitoring, enhanced reliability, and extended service life of the equipment.

Sanitary And Clean Services In Pressure Vessel Design and Engineering

Cleanability is a key design factor. Engineering specifies drainable geometry, smooth internal finishes, high-quality orbital welding, and compatible gaskets for clean-in-place chemicals. Validation relies on traceable surface finishes and material certifications, all documented to ensure compliance, maintainability, and reliable long-term performance.

Digital Thread, Data Control, And Practical Twins In Pressure Vessel Design and Engineering

Data discipline is leverage. Engineering links data sheets, CAD, calculations, weld maps, MTRs, NDE results, and test records. Using sensors, a practical digital twin aligns operational data with design assumptions, enabling refined inspection intervals and supporting condition-based maintenance for improved reliability, efficiency, and long-term asset performance.

Sustainability And Cost Optimization In Pressure Vessel Design and Engineering

Less mass and energy are achieved without cutting corners. Engineering optimizes head selection, nozzle count, support design, and insulation to reduce weight and energy use. Thoughtful material choices and welding consumables can lower embodied carbon. Life-extension strategies, carefully planned, often provide the best return on investment while ensuring safety and durability.

Project Delivery, Risk, And Change Control In Pressure Vessel Design and Engineering

Predictability wins. Engineering freezes critical inputs early, defines deliverables and hold points, and keeps calculations synchronized with drawing revisions. Make-or-buy decisions, transport limits, and field assembly constraints are addressed to avoid late surprises. Traceable changes are maintained throughout the project, protecting quality, ensuring schedule adherence, and supporting safe, reliable vessel fabrication and delivery.

Why Red River LLC For Pressure Vessel Design and Engineering

Owners benefit when a single accountable partner handles design, fabrication, and documentation. At Red River LLC, the team integrates calculations, detailed drawings, welding procedures, NDE, testing, and MDR creation. Practical engineering simplifies fabrication, shortens audits, and ensures vessels operate as intended. Red River LLC focuses on safety, schedule, and cost, delivering reliable, high-quality vessels. Learn more about their approach and services at https://www.redriver.team/.

Pressure Vessel Design and Engineering In Closing

Pressure Vessel Design and Engineering is the backbone of reliable pressure systems. When accurate inputs meet disciplined calculations and shop-ready details, Pressure Vessel Design and Engineering turns challenging process needs into compliant, maintainable assets. With clean documentation and risk-based inspection anchored in Pressure Vessel Design and Engineering, you reduce downtime and extend asset life with confidence.

Get Expert Help For Your Next Vessel

Partner with a team that lives the details. Red River LLC brings Pressure Vessel Design and Engineering together with fabrication, inspection, and documentation so your project moves from data sheet to nameplate without drama. Share your process conditions and let the team propose a practical, code-compliant plan. Start here: https://www.redriver.team/.

Frequently Asked Questions

1. What is pressure vessel design and engineering

Pressure Vessel Design and Engineering is the end-to-end process of transforming process requirements into a safe, code-compliant vessel. It includes defining loads and temperatures, selecting materials, sizing shells and heads, detailing welds and nozzles, planning NDE and tests, and compiling an MDR. In short, Pressure Vessel Design and Engineering keeps traceability from data sheet to nameplate.

2. How do you design a pressure vessel

You design a vessel by following a disciplined Pressure Vessel Design and Engineering sequence. Capture design pressure, temperature, corrosion allowance, and transients. Choose the code basis. Size shells and heads, design nozzle reinforcement, and check supports. Select materials, welding procedures, and PWHT. Plan NDE and tests, then compile the MDR. This is the practical answer to How do you design a pressure vessel using Pressure Vessel Design and Engineering.

3. What are the key factors in pressure vessel engineering

The key factors are accurate process data, correct code selection, credible load combinations, suitable materials and MDMT checks, qualified welding, targeted NDE, realistic tolerances, and a complete MDR. These factors are embedded in Pressure Vessel Design and Engineering and define success for integrity and cost. That addresses What are the key factors in pressure vessel engineering.

4. When should I choose a design by analysis path

Choose design by analysis when optimization, complex geometry, or high utilization is required. Pressure Vessel Design and Engineering then applies elastic-plastic or fatigue assessments, validates stress categories, and documents acceptance with the selected code methodology.

5. How should nozzle loads be handled

Integrate piping early. Pressure Vessel Design and Engineering obtains nozzle loads from piping stress, checks local stresses and reinforcement, and coordinates flexibility or spring supports. When loads are high, Pressure Vessel Design and Engineering adjusts pads, shell thickness, or geometry to keep margins.

6. What controls brittle fracture risk

Low temperature and high restraint raise risk. Pressure Vessel Design and Engineering validates MDMT, specifies impact-tested materials or PWHT, and manages heat input to keep ductility. Proper thickness at discontinuities is another lever in Pressure Vessel Design and Engineering.

7. What is the role of PWHT

PWHT reduces residual stress and improves toughness in certain alloys. Pressure Vessel Design and Engineering sets PWHT when required by code or beneficial for service. The plan includes soak temperature, hold time, and controlled heating and cooling with calibrated charts.

8. How does inspection planning connect to design

Inspection should target hot spots. Pressure Vessel Design and Engineering maps calculated stress raisers to inspection points, supports risk-based inspection, and adapts intervals using field data. This turns design insights into operational reliability.

Key Takeaways

- Engineering links process data, code rules, materials, welding, NDE, testing, and documentation into one accountable workflow.

- Early clarity in engineering prevents rework, optimizes thickness and head selection, and smooths audits.

- Targeted inspection plans reduce downtime and extend asset life.

- Red River LLC applies practical engineering to deliver clean drawings, qualified welding, complete NDE, and audit-ready MDRs.

Related Blog Post

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

Pressure Vessel Fabrication and Manufacturing: RedRiver LLC

About Author