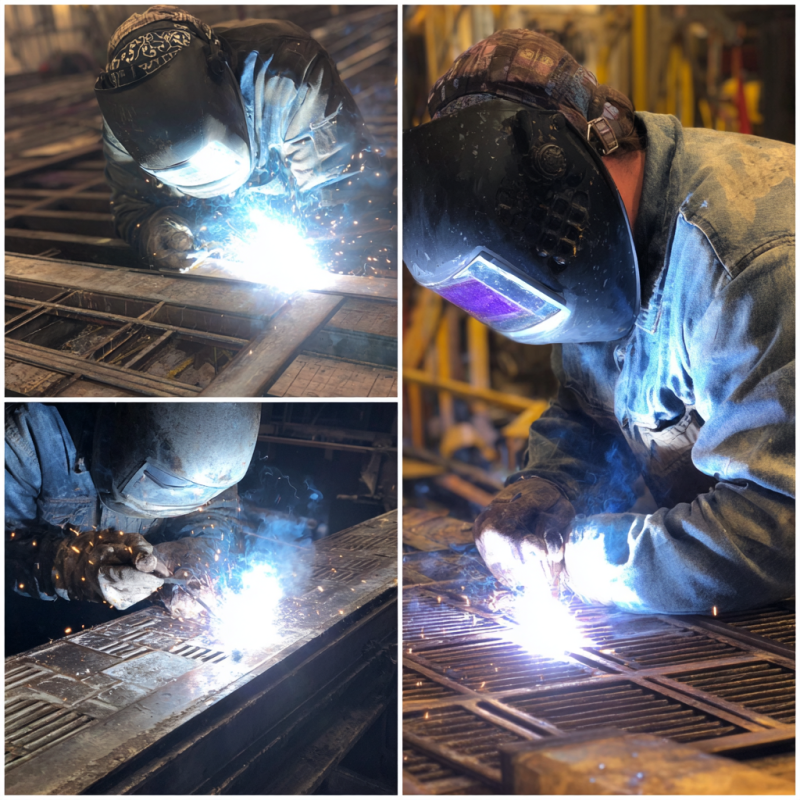

What Is 6G Welding Position? Master Advanced Pipe Welding

The 6G welding position fixes a pipe at a 45° angle, requiring welds in overhead, vertical, and horizontal orientations, making it one of the most challenging welding skills. Mastering it with proper technique, safety, and practice demonstrates advanced ability, improves employability, and prepares welders for high-pressure industrial projects. Why Understanding What Is 6G Welding Position […]

Which Welding Position Is the Easiest?

The flat (1G) welding position is the easiest for beginners because it provides a level surface, better visibility, and easier control of the weld pool. Mastering flat welding builds foundational skills that make progressing to horizontal, vertical, and overhead positions safer and more effective. Understanding Which Welding Position Is the Easiest If you are just […]

The Essential Guide: How Many Types of Welding Positions Are There?

There are six main groove welding positions (1G–6G) and four fillet positions (1F–4F), each testing different angles and skills. Beginners should start with the flat 1G position to build fundamentals before progressing to horizontal, vertical, overhead, and advanced pipe positions like 5G and 6G. Understanding How Many Types of Welding Positions Are There When learning […]

What Are the Different Welding Position Types and Their Benefits?

Welding positions range from 1G (flat) to 6G (angled pipe), each affecting technique, safety, and weld quality. Beginners start with easier positions like 1G, while mastering advanced ones like 6G improves skill, versatility, and efficiency for real-world projects. Understanding What Are the Different Welding Position Types You may find yourself asking, “What are the different […]

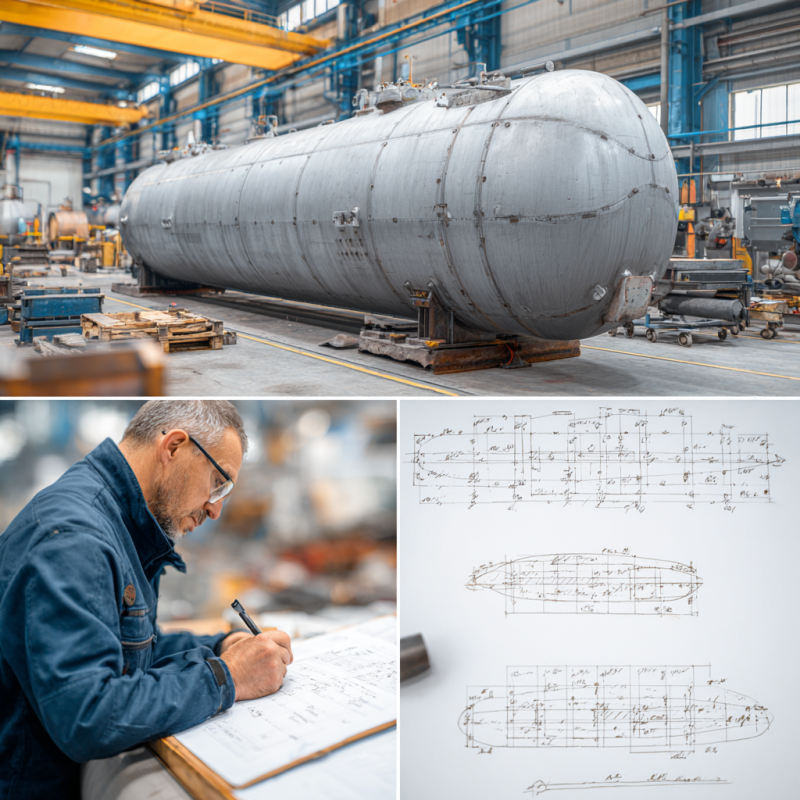

Which Welding is Best for Pressure Vessel? Get the Facts!

Choosing the best welding for pressure vessels depends on material, thickness, production needs, and code compliance, with common methods including TIG for precision, MIG for general fabrication, and SAW for thick steel. Advanced techniques, certified welders, and prefabrication in controlled environments ensure safer, high-quality welds that meet ASME standards and extend vessel lifespan. Understanding Which […]

How to Weld a Pressure Vessel: Techniques for Strong Joints

Welding a pressure vessel safely and effectively requires strict adherence to ASME codes, proper PPE, certified materials, a clean workspace, and controlled welding techniques like SMAW, GTAW, or GMAW. Thorough inspection, testing, and post-weld finishing ensure the vessel can withstand high pressures and remain reliable over time. Mastering How to Weld a Pressure Vessel Safely […]

What Is the Welding Procedure for Pressure Vessel

The welding procedure for a pressure vessel involves careful design, certified materials, qualified welders, controlled welding techniques, and thorough inspections to meet ASME code and ensure safety under high pressure. Prefabrication and strict quality control further reduce risks, improve efficiency, and ensure long-term reliability of the vessel. Understanding What Is the Welding Procedure for Pressure […]

What Are the Requirements for ASME Pressure Vessel Welding

ASME pressure vessel welding requires certified welders, approved materials, strict adherence to Section IX codes, thorough inspections, and complete documentation to ensure safety, reliability, and code compliance. Prefabrication in controlled environments further improves quality, reduces costs, and minimizes on-site risks while maintaining consistent, defect-free welds. Understanding What Are the Requirements for ASME Pressure Vessel Welding […]

How to Comply with ASME Pressure Vessel Welding Code

Complying with ASME pressure vessel welding code requires certified welders, approved materials with full traceability, controlled welding procedures, rigorous inspections, and thorough documentation to ensure safety and reliability. Prefabrication and consistent quality checks further reduce errors, speed up production, and help maintain full code compliance. Your Guide on How to Comply with ASME Pressure Vessel […]

What Is the ASME Pressure Vessel Welding Code

The ASME pressure vessel welding code sets strict standards for materials, welding procedures, inspections, and documentation to ensure vessels are safe, durable, and reliable under high pressures. Working with certified manufacturers and following these guidelines, including prefabrication and rigorous testing, minimizes risks, ensures compliance, and protects both workers and equipment. Understanding What Is the ASME […]