Separators are essential devices that split heterogeneous mixtures into usable components using gravity, magnetism, or centrifugal force. They’re widely used in industries like oil & gas and water treatment to boost efficiency, reduce waste, and meet environmental standards. Understanding the right type gravity, centrifugal, magnetic, or three-phase can significantly improve operational performance.

Exploring Separator Technology

Separators are vital devices used to split heterogeneous mixtures into usable components. From everyday examples like separating oil and water to advanced industrial systems in oil, gas, and water treatment, separators ensure efficiency, safety, and productivity. In this article, we’ll explore what separators are, how they work, the main types of separators, and their importance in different industries. Learn more about our capabilities and solutions in industrial processing.

What Is a Separator?

A separator is a piece of equipment designed to divide heterogeneous mixtures into their individual parts based on physical properties such as density, magnetism, or particle size. Unlike homogeneous mixtures, where substances blend uniformly, heterogeneous mixtures can be separated by mechanical or physical methods. Common examples include:

For an in-depth look at specialized separator types, check out our guide on liquid separators.

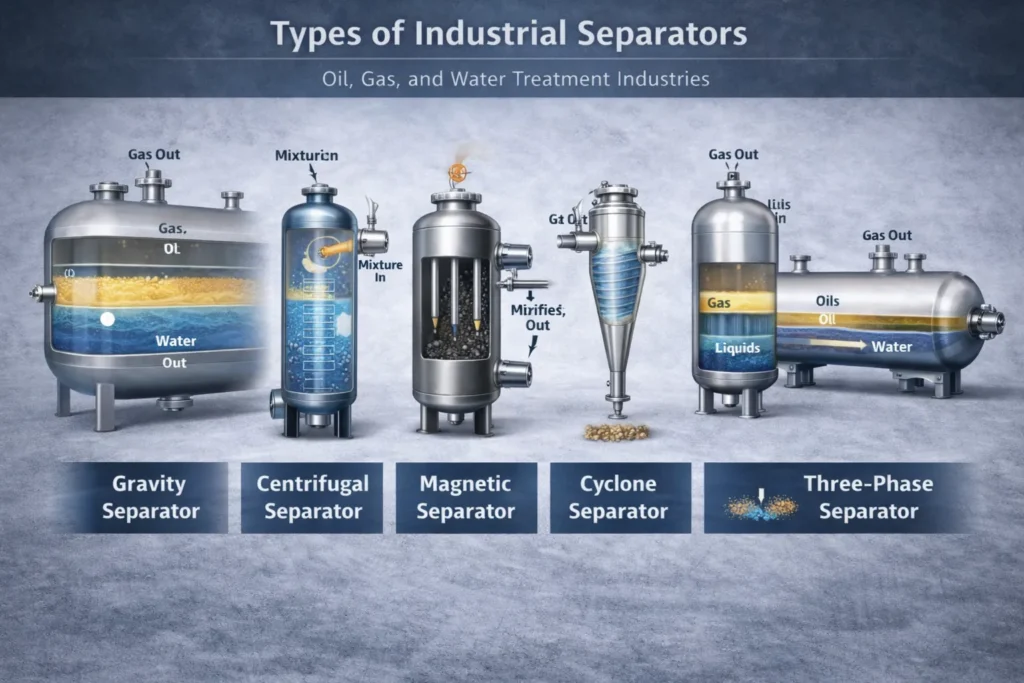

Types of Industrial Separators

Different industries rely on specialized separators designed for unique challenges:

- Gravity Separators – Use natural gravity to separate heavier materials from lighter ones. Learn how this applies in three-phase separators.

- Centrifugal Separators – Employ high-speed rotation to divide components by density. See our two-phase fluid systems for more applications.

- Magnetic Separators – Use magnetic fields to pull ferrous materials from mixtures, related to metal fabrication.

- Cyclone Separators – Generate a vortex to remove particulates from gases or liquids. Check out our modular skids for integrated designs.

- Three-Phase Separators – Separate gas, oil, and water simultaneously, especially useful in oil & gas. Explore three-phase separators in detail.

If you’re working in oil-water processing, our oil-water separator guide provides detailed insights.

How Do Separators Work?

Separators operate using physical principles:

- Gravity separation: Splits liquids like oil and water based on density differences. Learn about pressure vessels that integrate these systems.

- Centrifugal separation: Spins mixtures rapidly to accelerate separation by density. Explore air receiver tanks for gas-liquid systems.

- Magnetic separation: Pulls out ferrous contaminants using magnetic force, connected to metal production processes.

- Cyclone separation: Traps airborne dust or liquid droplets through vortex flow. See desiccant dryers for particulate removal in air systems.

For environmental and industrial processes, separators help reduce waste, improve product quality, and ensure compliance with environmental standards. According to ScienceDirect, separators are critical for efficient fluid and solid separation. The American Petroleum Institute also provides standards guiding safe separator design and operation.

Industrial Benefits of Separators

Industries benefit from separators in multiple ways:

- Improved product quality: Cleaner outputs for manufacturing and processing. See quality assurance in pressure tanks.

- Reduced waste: Lower disposal costs and environmental impact. Learn about environmentally conscious skids.

- Lower operational costs: Efficient processes mean less energy use, linked to prefabrication methods.

- Sustainability: Better compliance with environmental regulations. Explore capabilities in water and gas treatment.

For example, in water treatment facilities, specialized water separators ensure impurities are removed before recycling or safe discharge.

The Power of Separator Technology

Separators are more than just industrial equipment they are the backbone of efficient and sustainable operations in science and industry. From basic oil-water separation to advanced three-phase systems, separators ensure quality, safety, and performance across multiple fields. By understanding the types, functions, and benefits of separators, businesses can unlock long-term efficiency and reliability.

Ready to Transform Your Operations with Separator Solutions?

Looking for high-performance separator solutions tailored to your operations?

Partner with Red River today. We design and manufacture American-made separators built to meet the most demanding industrial needs. Contact us to find the right separator for your business.

Frequently Asked Questions

1. What is the easiest way to separate heterogeneous mixtures?

Simple techniques like filtration, decantation, and magnetism work for small-scale mixtures.

2. Which separators are used in the oil and gas industry?

Gravity separators, centrifugal separators, and three-phase separators are widely used.

3. Can separators be customized for specific industries?

Yes. At Red River, we specialize in designing separators tailored to unique operational challenges.

4. Are heterogeneous mixtures always separable?

Yes, but the method depends on the mixture’s properties such as density, particle size, or magnetism.

5. What is the difference between separating heterogeneous and homogeneous mixtures?

Heterogeneous mixtures can be separated by simple physical methods, while homogeneous mixtures often require advanced processes like distillation.

Key Takeaways

- A separator is an industrial device used to divide heterogeneous mixtures.

- Common types include gravity, centrifugal, magnetic, cyclone, and three-phase separators.

- Separators are critical in industries such as oil, gas, and water treatment.

- They improve efficiency, reduce waste, and support sustainability.

- Red River delivers customized, American-made separator solutions.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

- Understanding the 2 Types of Oil Water Separator

- Understanding the Difference Between Distillation and Separator

- Understanding the Purpose of a Water Separator

- Understanding Two-Phase Fluid Dynamics

- Understanding the Role of a 2-Phase Separator in Industrial Processes

- Liquid Nitrogen Phase Separator Essential for Efficient Cryogenic Systems