Pressure vessel safety standards and compliance prevent failures, hazards, and downtime by ensuring strict adherence to engineering rules and ASME codes. RedRiver LLC follows these standards through inspections, documentation, and maintenance to deliver reliable, code-compliant vessels.

Understanding Pressure Vessel Safety Standards and Compliance

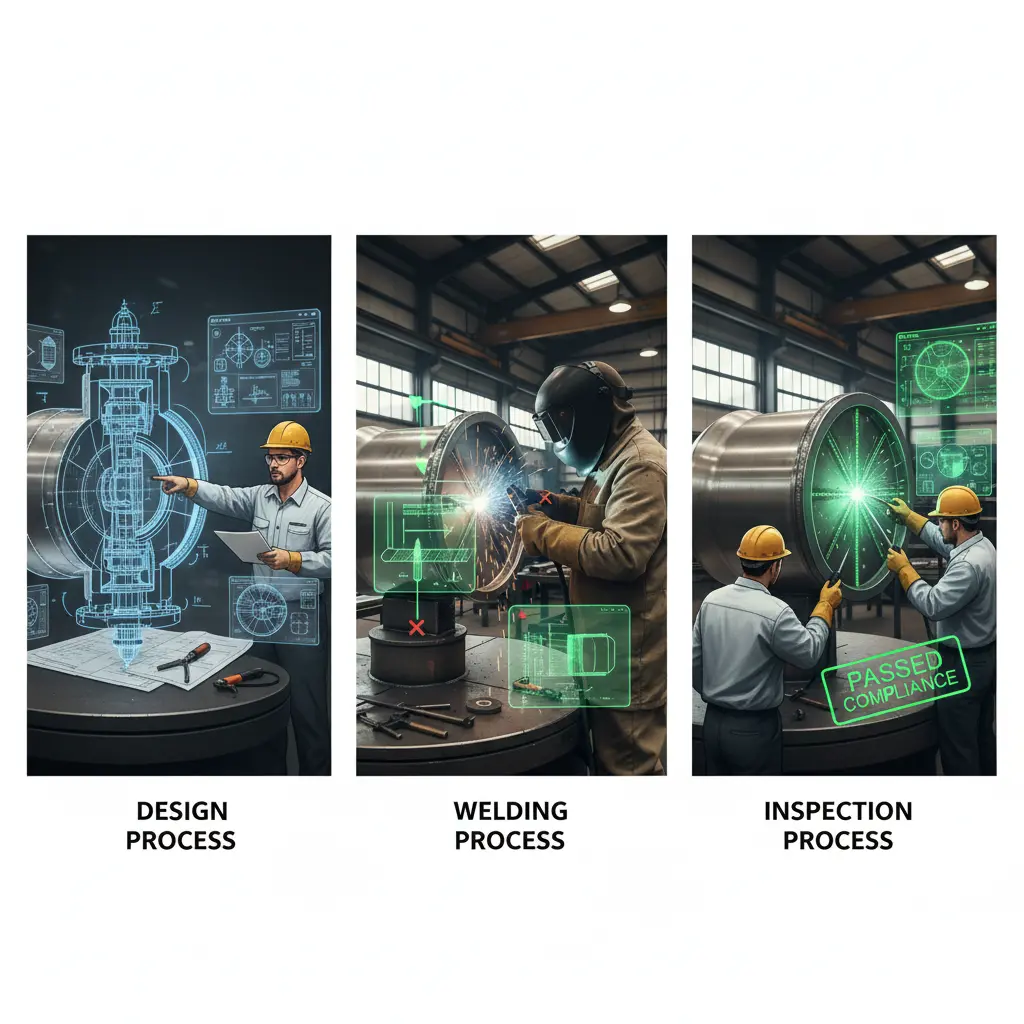

Pressure Vessel Safety Standards and Compliance form the foundation of safe design, fabrication, testing, and operation for any pressure-retaining equipment. Because pressure vessels store gases and liquids under high internal pressure, even small defects can escalate into dangerous failures. That is why safety standards exist: to define the rules, calculations, inspections, and documentation necessary to ensure structural integrity. These principles govern everything from allowable stress limits to materials, welding procedures, and pressure vessel inspection and maintenance practices required throughout a vessel’s lifespan.

Why Pressure Vessel Safety Standards and Compliance Matter

Pressure vessels must perform under extreme conditions, including internal pressure, heat, corrosion, vibration, and environmental exposure, all of which affect long-term performance. Adhering to Pressure Vessel Safety Standards and Compliance ensures these vessels remain structurally reliable under such demanding conditions. Without proper adherence, even minor defects can lead to catastrophic failures. Engineers implement Pressure Vessel Safety Standards and Compliance during design, material selection, and fabrication to manage risks effectively. Regular inspections and testing further reinforce Pressure Vessel Safety Standards and Compliance, while proper documentation ensures traceability. Ultimately, following Pressure Vessel Safety Standards and Compliance protects workers, equipment, and operational continuity in all industrial applications.

Using Pressure Vessel Safety Standards and Compliance reduces risks through:

- Consistent engineering design rules

- Verified material selection

- Reliable welding procedures

- Mandatory inspections

- Traceable documentation

- Certified quality-control processes

These expectations ensure that vessels can withstand long-term pressure cycles, unexpected surges, harsh chemicals, and demanding operational environments. RedRiver LLC integrates these standards during every phase of fabrication, from early engineering assessments to the final hydrotest, making compliance a built-in part of the manufacturing workflow.

Key Components of Pressure Vessel Safety Standards and Compliance

ASME Codes and Their Role

When exploring “What are the safety standards for pressure vessels,” ASME Boiler and Pressure Vessel Code is the most essential reference. This code establishes comprehensive rules for design, fabrication, inspection, testing, and documentation that ensure each vessel operates safely under pressure. It defines material specifications, welding procedures, stress analysis requirements, and rigorous testing methods to prevent failures. Compliance with the ASME Boiler and Pressure Vessel Code guarantees that vessels meet internationally recognized safety standards. Engineers, fabricators, and inspectors rely on it to verify every stage of production, ensuring reliability, traceability, and long-term performance. Ultimately, adherence to this code protects both operators and end-users.

To answer “What is ASME code for pressure vessel safety,” ASME Section VIII outlines:

- Allowable stress calculations

- Material properties and requirements

- Forming and welding procedures

- Heat treatment expectations

- Repairs and alterations

- Testing methods such as hydrostatic or pneumatic testing

- Required data reports and nameplates

Understanding how pressure vessels meet safety requirements begins with strict adherence to Pressure Vessel Safety Standards and Compliance from the start of a project. Following the ASME code ensures all design rules are met, materials are approved, and welding procedures are correctly executed. Mandatory inspections and testing reinforce Pressure Vessel Safety Standards and Compliance, while complete certification and documentation maintain traceability. Engineers rely on Pressure Vessel Safety Standards and Compliance to guide fabrication, installation, and long-term operation, reducing risk of failure. Ultimately, maintaining Pressure Vessel Safety Standards and Compliance protects personnel, equipment, and processes, ensuring vessels operate safely and reliably under extreme conditions in all industrial applications.

Materials and Engineering Requirements

Proper material selection is central to Pressure Vessel Safety Standards and Compliance. This includes ensuring materials meet ASME standards, have proper mechanical properties, and are traceable to approved suppliers.

Engineers evaluate:

- Strength

- Temperature resistance

- Corrosion resistance

- Weldability

- Service environment compatibility

Having complete documentation for all materials is essential to meet Pressure Vessel Safety Standards and Compliance. This traceability ensures that every piece of steel used in fabrication aligns with code requirements and is safe for the intended pressure conditions. Engineers rely on Pressure Vessel Safety Standards and Compliance to guide material selection, welding procedures, and fabrication processes. Proper records support inspections and testing, reinforcing Pressure Vessel Safety Standards and Compliance throughout the vessel’s lifecycle. By adhering to Pressure Vessel Safety Standards and Compliance, organizations maintain structural integrity, minimize operational risks, and ensure personnel safety, equipment reliability, and long-term compliance with regulatory requirements in all industrial applications.

Design Considerations and Stress Management

A major part of compliance involves understanding how internal pressure affects the structure. This involves concepts such as stress limits, allowable stress values, and detailed stress analysis methods. These concepts directly relate to Pressure Vessel Stress Analysis and Calculations and help determine wall thickness, reinforcement needs, pressure ratings, and overall vessel geometry.

Addressing what is pressure vessel stress analysis involves evaluating hoop stress, longitudinal stress, and radial stress. Engineers use these calculations to determine what types of stresses a vessel experiences and ensure it can handle pressure without exceeding material limits. Following Pressure Vessel Safety Standards and Compliance ensures that stress evaluations are performed correctly and align with ASME rules. All design decisions, including wall thickness, reinforcements, and pressure ratings, rely on Pressure Vessel Safety Standards and Compliance to maintain safety and reliability. By adhering to Pressure Vessel Safety Standards and Compliance, engineers can prevent failures and guarantee operational integrity. Proper documentation supports Pressure Vessel Safety Standards and Compliance throughout the vessel’s lifecycle.

Welding Requirements for Code Compliance

Welding is one of the biggest factors in pressure-vessel safety. All welds must follow code-approved procedures, performed by certified welders. This directly relates to Welding in Pressure Vessel Engineering and explains “What is welding in pressure vessel engineering.”

Code-approved welding includes:

- Approved Welding Procedure Specifications (WPS)

- Welder qualification tests

- Controlled heat input

- Inspection of weld surfaces

- Non-destructive testing

- Documentation of all welding activity

Understanding how welding is used in pressure vessel fabrication is essential because weld quality directly affects a vessel’s ability to withstand pressure safely. Following Pressure Vessel Safety Standards and Compliance ensures that welding procedures, welder qualifications, and heat control meet stringent requirements. Engineers rely on Pressure Vessel Safety Standards and Compliance to select appropriate welding methods, perform inspections, and document all processes accurately. Adhering to Pressure Vessel Safety Standards and Compliance reduces the risk of weld defects and structural failures. Proper implementation of these standards guarantees that vessels maintain integrity under extreme conditions and that maintenance, testing, and documentation align with Pressure Vessel Safety Standards and Compliance throughout their lifecycle.

This process also includes knowledge of What are the common welding methods for pressure vessels, including:

- TIG welding

- MIG welding

- SMAW welding

- Submerged arc welding

- Orbital welding (5G welding position)

RedRiver LLC implements advanced welding practices to ensure flawless joints and long-term reliability in every pressure vessel they fabricate. Each weld is carefully planned, executed, and inspected according to strict industry standards, guaranteeing structural integrity under extreme operating conditions. RedRiver LLC combines skilled craftsmanship with cutting-edge technology, using precise techniques to minimize defects and maximize performance. Their commitment extends beyond welding, encompassing thorough documentation, quality control, and adherence to all relevant codes and regulations. By maintaining meticulous records and following best practices at every stage, RedRiver LLC ensures that every unit meets or exceeds client expectations, providing safety, durability, and confidence in every project delivered.

Inspection and Testing as Part of Compliance

Meeting Pressure Vessel Safety Standards and Compliance requires thorough inspections throughout fabrication. This aligns with Pressure Vessel Inspection and Maintenance, including questions like:

- Pressure Vessel Inspection and Maintenance

- How often do pressure vessels need to be inspected

- How to inspect a pressure vessel

- What to include in a pressure vessel inspection checklist

Inspections ensure that all design rules, material requirements, and welding procedures are met. Mandatory testing includes hydrotesting, where water is pressurized inside the vessel to verify structural integrity. Non-destructive examination is also used to detect weld defects or material inconsistencies.

A typical inspection checklist includes:

- Visual weld examination

- Dimensional accuracy checks

- Verification of materials

- Hardness testing

- Paint and coating inspections

- Documentation review

These steps support long-term safety and ensure the vessel complies not just at installation, but throughout its lifecycle. Maintaining proper inspections, testing, and documentation is critical to meeting Pressure Vessel Safety Standards and Compliance. Engineers follow these standards to verify material integrity, weld quality, and overall vessel design, reducing the risk of structural failure. Adhering to Pressure Vessel Safety Standards and Compliance provides clear guidelines for ongoing maintenance, recordkeeping, and operational checks. By consistently applying Pressure Vessel Safety Standards and Compliance, organizations safeguard personnel, protect equipment, and ensure reliable performance under high-pressure conditions, helping vessels operate safely and efficiently over their entire service life.

Documentation and Traceability

Pressure Vessel Safety Standards and Compliance require extensive documentation. ASME rules mandate that every vessel has a complete data package, including:

- Certified material test reports

- Welding procedure documentation

- Welder certifications

- Inspection and testing records

- Non-destructive testing reports

- Final nameplate information

Traceability is a cornerstone of safe and compliant pressure vessel fabrication. It ensures that every step, from material selection to final inspection, meets established code requirements and can be verified at any stage of the process. RedRiver LLC upholds this standard rigorously, maintaining detailed, precise records for every unit manufactured. These records document materials, procedures, welding, testing, and quality checks, providing full transparency and accountability. By doing so, RedRiver LLC not only guarantees compliance but also enhances safety, reliability, and confidence for clients. Traceability is more than documentation it’s an essential practice that protects both the manufacturer and end-users.

Maintenance and Long-Term Safety Compliance

Pressure vessels require recurring inspections to maintain safety. Operators must evaluate corrosion, cracking, deformation, and changes in operating conditions. When understanding “How often do pressure vessels need to be inspected,” the timeline varies based on service environment, but regular internal and external checks are essential. RedRiver LLC supports operators through guidance on best practices for inspection intervals, recordkeeping, repairs, and vessel modifications.

Pressure Vessel Safety Standards and Compliance

Pressure Vessel Safety Standards and Compliance form the backbone of safe pressure-vessel design, fabrication, installation, and long-term operation. These standards protect workers, equipment, and businesses by defining strict rules for engineering design, weld quality, inspection procedures, material selection, and regulatory documentation. By applying ASME codes, following structured inspection processes, and maintaining complete traceability, organizations prevent failures and maintain operational reliability. RedRiver LLC ensures that every project meets these safety requirements at every step, providing high-quality pressure vessels built with robust engineering and full compliance in mind.

Discover Precision-Engineered, Code-Compliant Pressure Vessels with RedRiver LLC

RedRiver LLC delivers safe, durable, and fully compliant pressure vessels built with precision engineering and meticulous quality control. Explore more at RedRiver LLC.

Frequently Asked Questions

1. What are the safety standards for pressure vessels?

Safety standards define the rules for design, testing, inspection, and documentation to ensure vessels operate safely under pressure.

2. What is ASME code for pressure vessel safety?

The ASME Boiler and Pressure Vessel Code provides the rules for design, fabrication, inspection, and certification.

3. How do pressure vessels comply with safety regulations?

Compliance is achieved by using approved materials, certified welders, code-compliant design, required inspections, and proper documentation.

4. How often do pressure vessels need to be inspected?

Inspection timing depends on service conditions, materials, and operating environment, but routine internal and external inspections are required.

5. How to inspect a pressure vessel?

Inspections include checking welds, coatings, dimensions, corrosion levels, and performing non-destructive testing when needed.

6. What to include in a pressure vessel inspection checklist?

A checklist includes weld examination, thickness evaluation, documentation verification, coatings, and safety-device evaluations.

7. What is Pressure Vessel Inspection and Maintenance?

It refers to ongoing evaluations and repairs to keep the vessel code-compliant and functioning safely.

8. What happens if a pressure vessel fails to meet compliance?

Non-compliant vessels face shutdown, repair requirements, or safety hazards.

KEY TAKEAWAYS

- Pressure Vessel Safety Standards and Compliance protect equipment, workers, and operations.

- ASME codes establish the rules for design, welding, testing, and documentation.

- Regular inspections are essential for long-term safety and performance.

- RedRiver LLC integrates compliance into every stage of fabrication.

- Proper maintenance prevents failures and supports reliable vessel operation.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author