How to Perform Fatigue Failure Analysis? Red River LLC

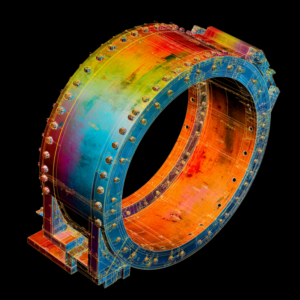

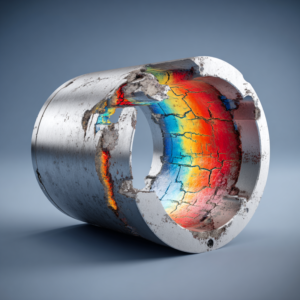

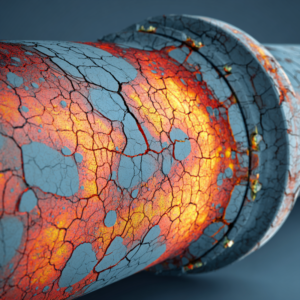

Performing fatigue failure analysis involves gathering operational and material data, using methods like visual inspection, nondestructive testing, fractography, and computational tools such as S-N curves and finite element analysis. Identifying fatigue triggers like cyclic loading, environmental factors, and design flaws helps prevent crack growth. Combining thorough inspection schedules, quality materials, and advanced modeling ensures safer, longer-lasting industrial components. Mastering How to Perform Fatigue Failure Analysis Fatigue failure is often cited as a major cause of mechanical breakdown in heavy industries,