Fatigue failure analysis is crucial for identifying early signs of material damage caused by repeated stress, especially in high-risk components like pressure vessels. It helps prevent catastrophic failures, enhances safety, reduces downtime, and extends equipment lifespan through proactive maintenance and inspections.

Understanding Why Is Fatigue Failure Analysis Important

Fatigue failure occurs when a material is weakened by repeated stress cycles, eventually causing cracks and structural breakdown. These stresses might not seem large at first, but over time, they accumulate and result in serious damage. If you work with pressure vessel fabrication or other critical infrastructure, small cracks can quickly become catastrophic faults. Analyzing fatigue proactively allows you to plan repairs, maintain safe conditions, and optimize your equipment’s lifespan.

At Red River LLC, safety and quality are core values. Fatigue failure analysis is embedded in daily practices through rigorous quality checks, alignment with ASME standards, and thorough material inspection. For insights into failures in these systems, explore our pressure vessel failure analysis resources.

How Fatigue Weakens Materials

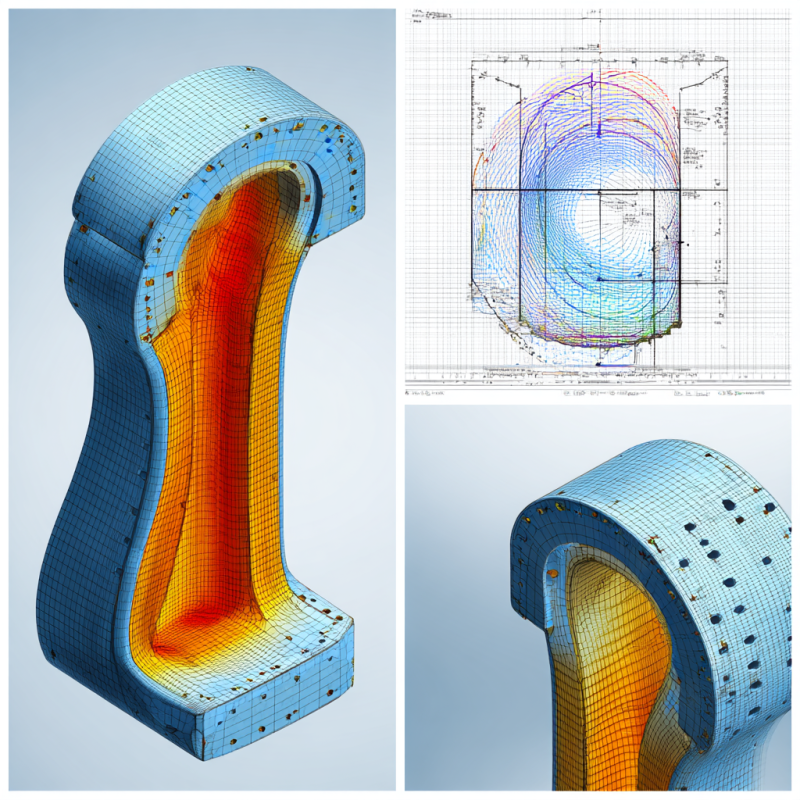

Fatigue is not about sudden overloads. Instead, it is a gradual process of hairline cracks forming under normal running conditions. Each stress cycle, such as internal pressure in a vessel or vibrations from heavy machinery, pushes the microscopic structure of the metal. If you overlook these signs, the damage accumulates until a sudden fracture occurs. Analyzing these patterns before they become critical helps you prevent major breakdowns, saving you from emergency shutdowns and expensive repairs.

Good news, this is more approachable than it sounds. There are non-destructive tests and advanced inspections that spot early-stage cracks. With consistent monitoring, you can detect tiny warning signs and address them long before they become a danger. Fatigue failure analysis is often paired with other inspection methods, like material failure analysis, to ensure you cover the entire chain of potential weaknesses.

Recognize Common Fatigue Triggers

If you want to protect your systems, start by identifying factors that elevate fatigue risk. These include:

- Repetitive loads: Mechanical parts enduring repetitive stresses are prime targets for fatigue cracks.

- Corrosive environments: Humidity, chemicals, or salt can degrade the protective surface of metals and speed up crack growth.

- Temperature extremes: Rapid thermal cycling causes expansion and contraction. Over time, that movement weakens the structure.

- Poor design or weld quality: Even a small mismatch in weld alignment can concentrate stress in a specific spot, creating a hotspot for fatigue.

Every facility is unique. For instance, chemical plants face thermal fluctuations, while energy facilities may contend with abrasives. Mapping these triggers supports a targeted maintenance plan focusing on vulnerable points first.

Influence of Manufacturing Quality

A strong manufacturing culture, like Red River LLC’s, embeds safety across design, fabrication, and testing. Controlled prefabrication reduces errors, while strict material traceability ensures all welds and joints are inspected before use.

Increase Safety, Cut Downtime

Unplanned downtime is costly and dangerous. Integrating fatigue failure analysis into maintenance programs prevents unexpected failures. By following ASME-certified pressure vessel standards, Red River LLC minimizes cracks, leaks, and ruptures in critical equipment.

Cost-effectiveness in the Long Run

Catching fatigue cracks early saves money by avoiding major repairs, legal issues, and emergency downtime. Regular inspections based on stress profiles allow planned maintenance, boosting productivity and reducing unexpected costs. For more insight, explore mechanical failure analysis to understand all types of mechanical stresses.

Practical Steps to Analyze Fatigue

You do not need to be a scientist to grasp the basics of testing for fatigue. The steps often include:

- Visual inspection: Start with a thorough visual check to spot discoloration, surface cracks, or unusual wear.

- Non-destructive examination (NDE): Methods such as ultrasonic testing or radiographic imaging can reveal hidden flaws. These tests are safe for your equipment because they do not damage the part.

- Stress measurement: Identify how much load your component experiences in real conditions. This data informs you where the most critical stress cycles occur.

- Crack growth modeling: If you find cracks, you can estimate how fast they will grow, which helps you prioritize repairs.

- Regular monitoring: By repeating these steps over time, you build a trend of your component’s health. That record helps you catch fatigue before it escalates.

For deeper insight, explore how to perform fatigue failure analysis and pressure vessel inspection procedures.

Role of Controlled Environments

Prefabrication in climate-controlled facilities reduces weather-related issues, cuts costs, and accelerates schedules. Integrated modeling software catches errors early, optimizing vessels for fatigue behavior and resistance before deployment.

Lifespan and Return on Investment

Thorough fatigue assessment prolongs equipment life. Maintaining stress below critical thresholds ensures components meet their design life. Red River LLC, an ASME-certified pressure vessel manufacturer, demonstrates how analysis of fatigue behavior translates into tangible ROI: fewer accidents, reliable performance, and extended system longevity.

Why Is Fatigue Failure Analysis Important for Long-Term Success

Fatigue failure analysis is a cornerstone of safe, reliable operations. By spotting subtle damage before it escalates, you safeguard your workforce, maintain output, and protect your investments. This proactive strategy builds a culture of safety and ensures long-lasting performance across all equipment.

Strengthen Your Operations with Proven Analysis

Don’t wait for cracks to become crises. Take control of your maintenance program today and integrate professional fatigue failure analysis into your system. Partner with experts like Red River LLC to ensure safety, reliability, and profitability.

Frequently Asked Questions

1. What is fatigue failure analysis

Fatigue failure analysis is the process of examining materials or components that have fractured due to repeated or cyclic stress over time. It identifies the causes, mechanisms, and contributing factors of fatigue to prevent future failures.

2. How to perform fatigue failure analysis

Fatigue failure analysis typically involves visual inspection, fractography using microscopes, material testing, and stress analysis. Engineers also review loading history, environmental conditions, and perform simulations to identify the root cause.

3. How often should I perform fatigue failure analysis?

It depends on your equipment load cycles and operational environment. Many facilities align inspections with scheduled shutdowns or conduct them yearly if conditions are stable. Keep an eye on high-stress areas, and adjust the frequency if you notice more wear and tear than usual.

4. Do all pressure vessels need fatigue failure analysis?

In most cases, yes. Pressure vessels face cyclical loading and pressure changes that create an ideal environment for fatigue. Having a regular inspection routine reduces the risk of a sudden break. You can also consult what are common pressure vessel failures to see other failure modes worth monitoring.

5. What type of testing do I need for small cracks?

Non-destructive tests, like ultrasonic, dye penetrant, or radiographic checks, can catch minute cracks. Once you locate a crack, you can use fracture mechanics to project how fast it might spread.

Key Takeaways

- Identify risks early: Repeated stress can create cracks that grow silently. Frequent inspection helps you catch and fix these flaws.

- Lower downtime expenses: A thorough analysis plan means fewer unplanned disruptions and more consistent production.

- Boost safety: Fatigue failure analysis protects your workforce and helps avoid workplace accidents.

- Match your environment: Tailor inspection intervals and methods to the level of stress, temperature, and corrosion your system faces.

- See long-term returns: By prioritizing analysis, you extend the life of your equipment and reap financial savings over time.