Why Use Aluminum Sheet Metal Fabrication? Red River LLC

This article explains why use aluminum sheet metal fabrication for efficient, corrosion-resistant, and sustainable projects. Learn how Red River LLC delivers top-quality aluminum prefabrication and fabrication solutions.

Understanding Why Use Aluminum Sheet Metal Fabrication

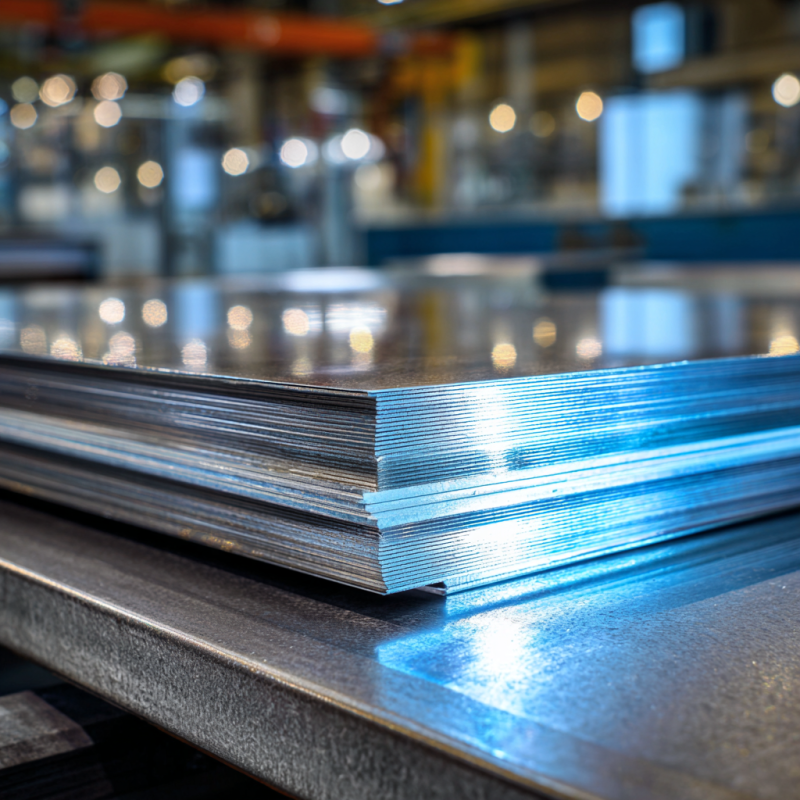

Aluminum sheet metal fabrication has become a go-to solution for countless projects, and if you’ve ever wondered why use aluminum sheet metal fabrication, you’re in the right place. You probably want sturdy, lightweight, and cost-effective materials for your builds. Aluminum delivers all that and more, making it a favorite in industries from energy to agriculture. In the next few sections, we’ll look at what aluminum sheet metal fabrication really means, how prefabrication saves you money, and how to find the best partner to get the job done.

Why Use Aluminum Sheet Metal Fabrication

Aluminum is often your go-to metal for everyday products you might take for granted, like car frames or window frames. When fabricated properly, it’s extremely versatile and easy to work with. It’s also well-suited for modular assemblies or facilities that need to meet strict safety and performance standards. Companies like Red River LLC highlight the lightweight properties, durability, and recyclability of aluminum, showcasing just how useful it can be across different industries.

You’ll see aluminum sheet metal used in everything from air filtration systems to large-scale energy production sites. Its rust-resistant nature and overall flexibility mean you can shape, weld, and install components quicker than with most other metals. If you’ve been curious about metal sheet fabrication in general, you’ll find that focusing on aluminum is one of the best decisions you can make.

Understand the Basics

Before you think about your next project, it helps to know exactly what aluminum sheet metal fabrication is and the benefits of aluminum sheet metal fabrication. Simply put, it’s the process of cutting, bending, and shaping aluminum sheets into the desired form. Understanding the benefits of aluminum sheet metal fabrication ensures you make smarter design and material choices.

Common Techniques Involved

- Cutting: This can be mechanical (like shearing) or thermal (such as laser cutting), allowing you to achieve precise shapes.

- Bending: Fabricators use press brakes or folding equipment to create angles and form the metal.

- Welding: Welding aluminum can be tricky, but specialized equipment and training ensure a solid, durable joint.

If you’d like a deeper dive into how these steps all fit together, take a look at what are the steps in the sheet metal fabrication process. Understanding the basics sets you up to make informed decisions about design, budget, and timelines.

Explore the Key Benefits

What sets aluminum apart from other metals like stainless steel? It comes down to a few standout factors that might just tip the scales in your favor, especially when choosing custom metal fabrication services for your project. Partnering with experts in custom metal fabrication services ensures precision, quality, and efficiency in every aluminum component you use.

- Lightweight structure: Aluminum weighs less than many metals, making handling easier and reducing shipping costs.

- Corrosion resistance: Naturally rust-resistant, ideal for coastal regions or humid climates (importance of material choice).

- Recyclability: Aluminum can be recycled repeatedly without losing properties (sustainability in fabrication).

- Cost-effectiveness: Lightweight and corrosion-resistant aluminum reduces maintenance and labor hours (custom sheet metal fabrication).

If you’re curious about other custom solutions, be sure to explore custom sheet metal fabrication. It highlights how fabrication can be adapted to match your specific project goals, saving you headaches or even entire budgets down the line.

Enhance Productivity with Prefabrication

Prefabrication builds components in controlled facilities before shipping to the job site.

- Speed and consistency: Indoor construction avoids weather delays and enhances workflow (modular skids).

- Fewer errors and better quality: Precise measurements reduce mistakes (quality control).

- Lower on-site exposure: Safer work environment and reduced insurance rates (ASME standards).

Check Popular Industry Applications

You might think aluminum is only used for a specific type of product. In reality, it shows up in multiple sectors:

- Energy production and distribution: Lightweight skids and modules meet safety standards.

- Agriculture: Aluminum resists corrosion from soil and weather (capabilities).

- Mineral extraction and chemical industries: Durable against chemicals and heat (solutions).

- Pressure vessels: If your project goes into high-pressure territory, you can rely on aluminum fabrications backed by thorough testing. Red River LLC, for instance, offers Custom/OEM Pressure Vessels that handle various pressure conditions, meeting demanding quality standards.

For an in-depth comparison of different metals, consider checking out what is stainless steel sheet metal fabrication. Understanding the pros and cons can clarify whether aluminum remains your best bet or if there’s a steel alternative that fits better.

Collaborate with a Trusted Manufacturer

Knowing what you want is only half the journey. You also need a skilled, forward-thinking partner experienced in industrial aluminum fabrication processes to bring your vision to life. Working with experts in industrial aluminum fabrication processes ensures your project meets high standards of quality, safety, and efficiency from start to finish.

Top qualities to look for:

- Technical expertise: Skilled in advanced aluminum fabrication (capabilities).

- Streamlined process: Efficient lean manufacturing (prefabrication).

- Solid quality control: ASME-approved inspections (ASME certification).

Red River LLC has emphasized its commitment to quality and American manufacturing, with rigorous testing protocols (Red River LLC Team). You’ll want similarly thorough practices wherever you decide to partner.

Continuous Improvement

Leading fabricators are also investing in the future. They track new software, follow advanced welding methods, and adapt to changes in regulatory guidelines. That way, your final product isn’t just good it’s also prepared for the next wave of innovation.

Why Use Aluminum Sheet Metal Fabrication for Modern Projects

If you value reliability, cost-efficiency, and eco-friendliness, it’s easy to see why aluminum sheet metal fabrication is the smarter choice. Its lightweight design simplifies logistics, while prefabrication cuts downtime and enhances quality.

Red River LLC continues to lead in delivering modular aluminum systems that meet stringent safety and environmental standards proving that aluminum isn’t just a smart material choice, but a long-term investment in project success.

Partner with Red River LLC for Aluminum Fabrication Excellence

Looking for a team that understands exactly why use aluminum sheet metal fabrication matters?

Contact Red River LLC today to discuss your custom aluminum fabrication needs and discover how prefabrication can transform your next build.

Frequently asked questions

1. What is aluminum sheet metal fabrication?

Aluminum sheet metal fabrication is the process of cutting, bending, shaping, welding, and finishing aluminum sheets into functional components or structures for various applications, from automotive panels to industrial equipment.

2. How does aluminum sheet metal fabrication work?

The process involves selecting the appropriate aluminum sheet thickness, then using techniques like cutting, bending, stamping, welding, and finishing to shape it. Prefabrication in controlled environments can improve efficiency, quality, and safety while reducing onsite labor.

3. Is aluminum sheet metal fabrication expensive compared to steel?

The initial material cost for aluminum can be higher, but you often save in the long run due to lower maintenance and the metal’s lighter weight, which reduces shipping and labor costs.

4. How long does aluminum sheet metal last in harsh conditions?

With proper fabrication and finishing, aluminum can last for decades, even in demanding environments like chemical plants or rugged, high-pressure applications.

5. Is prefabrication only for large industrial projects?

Not at all. While large-scale industries definitely benefit, smaller or midsize projects also see cost and time savings by fabricating modules offsite before final assembly.

6. Can aluminum sheet metal be recycled if I need to replace it?

Yes. One of the biggest advantages is that aluminum can be recycled multiple times without losing quality. It’s a perfect fit if you care about minimizing waste.

7. How do I choose the right thickness for my aluminum sheet?

It depends on the structural requirements of your project. A good fabrication partner will help you analyze stress factors, weight demands, and design specifications to select the right gauge.

8. Where should I start if I need a custom design?

Start by discussing your project goals with a reputable fabricator. They’ll guide you through design considerations, material options, and the overall sheet metal fabrication process to ensure your final build meets every requirement.

Key Takeaway

- Aluminum’s lightweight properties reduce shipping costs and speed up onsite assembly.

- Corrosion resistance makes it a smart choice for outdoor and demanding environments.

- Prefabrication cuts delays, boosts quality, and improves workplace safety.

- Multiple industries, from energy to agriculture, depend on aluminum for durable components.

- Partnering with a trusted manufacturer ensures your projects meet high performance and safety standards.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author