This blog explains how often pressure vessels should be inspected and why inspections are crucial for safety and reliability. It also covers how organizations can follow pressure vessel safety standards and compliance including practical inspection checklists. RedRiver LLC is highlighted for providing dependable engineering, inspection, and maintenance support.

Understanding How Often Do Pressure Vessels Need to Be Inspected for Safe Operation

How often do pressure vessels need to be inspected is one of the most important questions engineers and facility operators must understand. Inspection schedules protect the equipment, the environment, and everyone who works around pressurized systems. Because pressure vessels operate under stress, heat, and chemical exposure, their internal and external conditions must be monitored regularly. That is why Pressure Vessel Safety Standards and Compliance include strict inspection requirements.

The frequency of inspections depends on vessel usage, operating conditions, and maintenance practices. Since every pressure vessel behaves differently, inspection schedules must be tailored to each system. RedRiver LLC assists companies by assessing vessel condition, understanding service demands, and creating code-compliant inspection plans that keep equipment safe and reliable.

Why Inspection Frequency Matters

Pressure vessels must operate within safe limits at all times. Understanding pressure vessel inspection frequency is essential, as internal pressure, corrosion, chemical exposure, thermal cycling, and environmental conditions can weaken the vessel. Proper pressure vessel inspection frequency ensures safety and reliability.

Inspections support:

- Preventive maintenance planning

- Early identification of corrosion and structural wear

- Long term equipment reliability

- Reduced risk of catastrophic failure

- Compliance with all safety requirements

Regular inspections also help teams understand how do pressure vessels comply with safety regulations. Without scheduled evaluations, hidden damage can develop into dangerous failures.

Factors That Influence How Often Do Pressure Vessels Need to Be Inspected

Pressure vessel inspection schedules are influenced by several operational and mechanical factors. Following the ASME code for pressure vessels ensures these factors are evaluated properly, as the ASME code for pressure vessels guides inspection cycles and compliance requirements.

Key influences include:

- Operating pressure and temperature

- Vessel material and thickness (choosing the right material)

- Internal contents and corrosiveness

- Environmental exposure

- Maintenance history and past repairs

- Vessel age and overall condition

- Code compliance requirements (ASME certification)

This is why many facilities rely on experts such as RedRiver LLC to assess inspection timelines. Compliance with regulations such as what is ASME code for pressure vessel safety is directly tied to how often inspections must be performed.

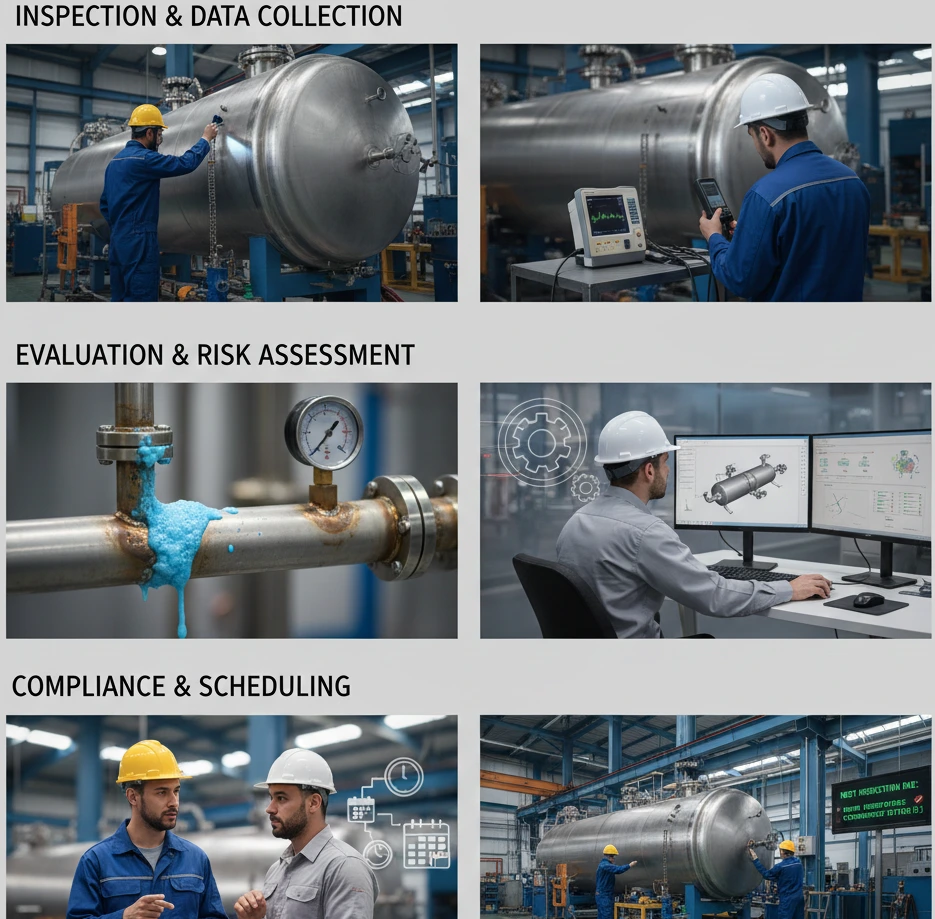

How Pressure Vessel Safety Standards and Compliance Affect Inspection Schedules

Pressure Vessel Safety Standards and Compliance define expectations for inspection frequency. These standards explain what are the safety standards for pressure vessels and outline the responsibilities of equipment owners and operators.

These standards emphasize:

- Material specifications

- Wall thickness requirements

- Documentation expectations

- Testing methods

- Inspection intervals

- Repairs and re-inspection guidelines

- Safety device requirements

- Qualifications of inspectors

Understanding these guidelines helps determine how often do pressure vessels need to be inspected. Codes require that inspections are not only routine but also thoroughly documented. RedRiver LLC ensures inspections meet all compliance levels while helping operators understand ongoing safety expectations.

How to Inspect a Pressure Vessel and Why the Process Supports Inspection Frequency

To understand how often do pressure vessels need to be inspected, it helps to understand how to inspect a pressure vessel effectively. A proper inspection requires internal evaluation, external examination, performance checks, and nondestructive testing methods.

A strong inspection process includes:

- Identifying corrosion, pitting, or thinning

- Checking for cracks or structural deformation

- Inspecting weld seams for defects (welding positions)

- Examining surface coatings and insulation

- Testing pressure relief devices

- Reviewing instrumentation and controls

- Confirming compliance with maintenance logs

- Documenting every inspection finding

This process is the foundation of Pressure Vessel Inspection and Maintenance. It reinforces consistent monitoring, helps determine inspection intervals, and supports long-term compliance.

What to Include in a Pressure Vessel Inspection Checklist

A pressure vessel inspection checklist ensures nothing is overlooked during the inspection process. It also supports regulatory expectations for documentation.

A thorough checklist may include:

- Vessel identification details

- Review of operating conditions

- Assessment of external surfaces

- Internal condition examination

- Analysis of corrosion and scaling

- Weld inspections and joint evaluations

- Relief valve and safety device checks

- Alignment and support assessment

- Review of Pressure Vessel Inspection and Maintenance history

- Verification of compliance documentation

Knowing what to include in a pressure vessel inspection checklist helps teams complete consistent and accurate inspections that meet all regulatory requirements.

Common Conditions That Impact Inspection Frequency

Assessing how often pressure vessels need to be inspected requires awareness of conditions affecting performance. Regular corrosion and pitting detection ensures issues are identified early, while ongoing corrosion and pitting detection helps adjust inspection schedules appropriately.

These conditions include:

- High internal corrosion rates (corrosion considerations)

- Frequent thermal cycling

- Chemical contamination

- Weld defects or previous repairs

- Signs of cracking or fatigue

- Internal scaling or deposits

- Changes in operating pressure

- Aging components

RedRiver LLC evaluates these conditions and makes recommendations for inspection intervals that align with real-world vessel behavior.

How Pressure Vessel Inspection and Maintenance Supports Consistent Safety

Pressure Vessel Inspection and Maintenance ensures ongoing compliance, helps evaluate structural condition, and keeps vessels operating safely. Without regular inspection and maintenance routines, vessel performance weakens and safety risks escalate.

Maintenance supports inspections through:

- Surface cleaning and corrosion protection

- Repair of damaged welds (welding expertise)

- Replacement of worn components

- Relief device testing

- Internal lining and coating checks

- Documentation of completed work

- Adjustments to inspection schedules

Together, inspection and maintenance build a strong safety foundation that answers how do pressure vessels comply with safety regulations year after year.

How Often Do Pressure Vessels Need to Be Inspected?

Understanding how often do pressure vessels need to be inspected helps organizations create safe, reliable, and compliant operations. Inspection frequency depends on vessel condition, operating environment, compliance standards, and maintenance history. RedRiver LLC helps companies determine inspection schedules, perform detailed inspections, and maintain full code compliance.

Get Professional Support for Your Pressure Vessel Inspections

RedRiver LLC provides expert engineering, maintenance, and inspection services that align with code requirements and safety expectations. Their team ensures pressure vessels are evaluated thoroughly and remain compliant throughout their entire lifecycle.

Learn more at: https://www.redriver.team/

Frequently Asked Questions

1. How often do pressure vessels need to be inspected

Pressure vessels require frequent external evaluations, internal assessments, and scheduled testing based on safety standards and operating conditions.

2. What are the safety standards for pressure vessels

Safety standards define material requirements, design expectations, inspection intervals, and testing procedures.

3. What is ASME code for pressure vessel safety

This code outlines the requirements for designing, fabricating, testing, and inspecting pressure vessels.

4. How do pressure vessels comply with safety regulations

Vessels comply by following industry codes, completing routine inspections, and maintaining proper documentation.

5. How to inspect a pressure vessel

Inspections involve checking structural components, welds, surfaces, corrosion, and safety devices.

6. What to include in a pressure vessel inspection checklist

A checklist includes documentation, corrosion checks, weld assessments, relief device inspections, and condition evaluations.

7. Why are inspections so important

Inspections prevent failures, improve safety, and extend equipment lifespan.

8. How does maintenance influence inspection intervals

Proper maintenance reduces wear and increases the time between inspections.

Key Takeaways

- Understanding how often do pressure vessels need to be inspected prevents failures and protects workers

- Inspection frequency depends on vessel condition, environment, and safety codes

- Checklists and maintenance plans support consistent inspection accuracy

- RedRiver LLC offers reliable, code-compliant inspection and maintenance solutions

- Regular inspections improve performance and extend vessel lifespan

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author